Determining the elongation of T-type pressure fire hoses based on full-scale experiments

DOI:

https://doi.org/10.15587/1729-4061.2023.279616Keywords:

fire hose, hose line, water transportation, geometric dimensions, fire hose extensionAbstract

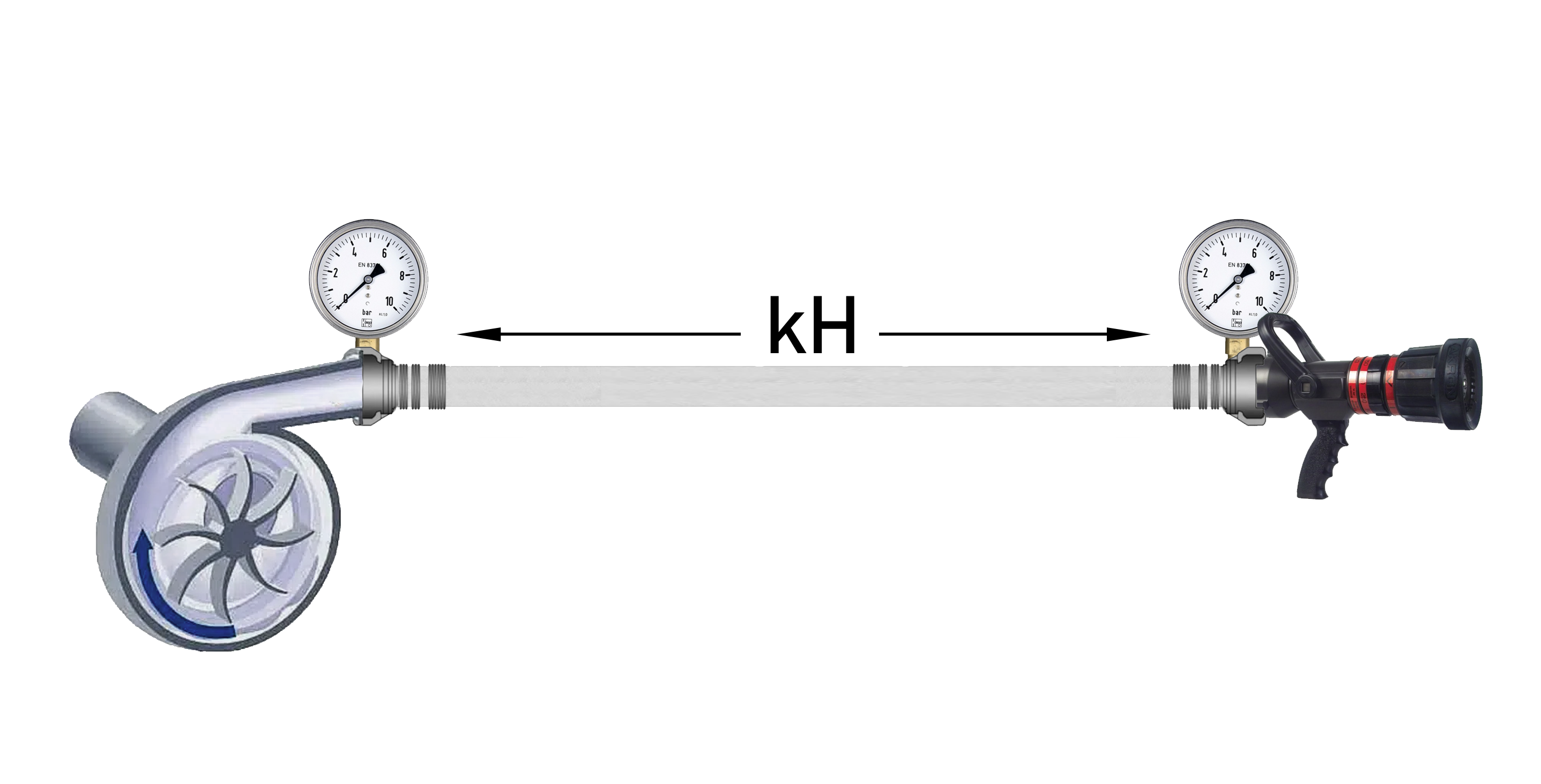

The phenomenon of changing the geometric parameters of pressure fire hoses is manifested when they transport extinguishing liquids. Although the extension of pressure fire hoses does not have a significant impact on the fire extinguishing process, the energy costs associated with such changes should be taken into account. In fact, part of the power of the fire pump is spent not on transporting liquids and forming extinguishing jets but on the «optional» lengthening of pressure fire hoses. Latex pressure fire hoses with diameters of 51 mm and 77 mm and fire pressure hoses with double-sided polymer coating of 51 mm (all of type T) were randomly selected for the experiments. The temperature was 263 K and 298 K, the fluid flow rate was constant, the pressure values at the inlet of the Protek 366 fire barrel had fixed values. No significant changes in the diameters (expansion or narrowing) of pressure fire hoses were recorded during water transportation. An elongation of 79 cm with a hose length of 1960 cm (73 cm with a hose length of 1790 cm) was recorded when transporting water in the case of using hoses with a diameter of 77 mm, a pressure at their inlet of 0.8 MPa, a temperature of 263 K, and a water flow rate of 0 l/s. The force that provided such a stretch was 2.04 kN. When extinguishing liquid was supplied by pressure fire hoses with a diameter of 77 mm in the temperature range of 263–298 K, the elongation decreased slightly with decreasing temperature. A slight unevenness of stretching of pressure fire hoses along the length was found when stretching increased closer to their middle. The results indicate the dependence of the amount of stretching on the materials from which pressure fire hoses are made, as well as their diameter. The values of dynamic forces that cause stretching of pressure fire hoses established in the study can be used in practice when taking into account the forced energy losses for fluid transportation

References

- Larin, A. N., Chernobay, G. A., Nazarenko, S. Y. (2014). Vyznachennia pozdovzhnoi zhorstkosti pozhezhnoho rukava. Problemy pozhezhnoi bezpeky, 35, 133–138. Available at: http://nbuv.gov.ua/UJRN/Ppb_2014_35_23

- Nazarenko, S., Kovalenko, R., Asotskyi, V., Chernobay, G., Kalynovskyi, A., Tsebriuk, I. et al. (2020). Determining mechanical properties at the shear of the material of “T” type pressure fire hose based on torsion tests. Eastern-European Journal of Enterprise Technologies, 5 (7 (107)), 45–55. doi: https://doi.org/10.15587/1729-4061.2020.212269

- Larin, O. M., Chernobai, H. O., Nazarenko, S. Yu., Zapolskyi, L. L. (2015). Vyznachennia dysypatyvnykh vlastyvostei napirnoho pozhezhnoho rukava typu «T» diametrom 77 mm. Naukovyi visnyk Ukrainskoho naukovo-doslidnoho instytutu pozhezhnoi bezpeky, 2 (32), 18–25.

- Larin, O., Morozov, O., Nazarenko, S., Chernobay, G., Kalynovskyi, A., Kovalenko, R. et al. (2019). Determining mechanical properties of a pressure fire hose the type of «T». Eastern-European Journal of Enterprise Technologies, 6 (7 (102)), 63–70. doi: https://doi.org/10.15587/1729-4061.2019.184645

- Cho, J. R., Yoon, Y. H., Seo, C. W., Kim, Y. G. (2015). Fatigue life assessment of fabric braided composite rubber hose in complicated large deformation cyclic motion. Finite Elements in Analysis and Design, 100, 65–76. doi: https://doi.org/10.1016/j.finel.2015.03.002

- Motorin, L. V., Stepanov, O. S., Bratolyubova, E. V. (2011). The simplified mathematical model for strength calculation of pressure fire hoses under hydraulic influence. Tehnologiya tekstil'noy promyshlennosti, 1, 126–133.

- Aripbayeva, A. E. et al. (2016). New Formula for Strength Calculation of Pressure Fire Hoses under Intrinsic Hydraulic Pressure. International Journal of Research in Engineering, IT and Social Sciences, 06 (12), 47–50. Available at: http://indusedu.org/pdfs/IJREISS/IJREISS_1022_58588.pdf

- Aripbaeva, A. E., Myrkhalykov, Zh. U., Koifman, O. I., Bazarov, Yu. M., Stepnov, S. G. (2016). Perspective direction of calculation and design of reinforcing carcasses of tension fire hoses on basis of synthetic fibers. Izvestiya vysshikh uchebnykh zavedenii khimiya khimicheskaya tekhnologiya, 59 (7), 92–95. doi: https://doi.org/10.6060/tcct.20165907.5406

- Aripbaeva, A. E., Mirkhalykov, Z. U., Kaldybaev, R. T., Koyfman, O. I., Bazarov, Y. M., Stepanova, S. M., Stepanov, S. G. (2020). Investigation of characteristics of woven reinforcing frames of pressure fire hoses and their influence on values of internal bursting pressures. Izvestiya vysshikh uchebnykh zavedenii khimiya khimicheskaya tekhnologiya, 63 (10), 96–104. doi: https://doi.org/10.6060/ivkkt.20206310.6234

- Anikin, S. N., Danilov, M. M., Denisov, A. N., Korolev, P. S., Litvinov, A. A. (2022). Algorithm of actions of fire service to extend high-pressure hoses when extinguishing a fire on the railway. Fire and Emergencies: Prevention, Elimination, 3, 99–109. doi: https://doi.org/10.25257/fe.2022.3.99-109

- Park, J., Kim, S.-J., Chun, K.-H. (2022). Verification of the Effectiveness of a Fire Hose Backpack in Areas Fire Trucks have Difficulty Accessing. Fire Science and Engineering, 36 (5), 134–141. https://doi.org/10.7731/kifse.db6da288

- Kim, H., Song, Y. (2021). A Study on the Durability of Fire Hoses of Fire Hydrants. Journal of the Korean Society of Hazard Mitigation, 21 (6), 97–102. doi: https://doi.org/10.9798/kosham.2021.21.6.97

- Prisyajnyuk, V., Semychayevsky, S., Yakimenko, M., Osadchuk, М., Svirskiy, V., Milutin, О. (2020). Analysis of structural compliance and basic technical requirements for layflat fire hoses for fire-rescue equipment. Series: Engineering Science and Architecture, 154, 324–327. doi: https://doi.org/10.33042/2522-1809-2020-1-154-324-327

- Prisyajnyuk, V., Semychayevsky, S., Yakimenko, M., Osadchuk, M., Svirskiy, V., Milutin, О. (2020). About improvement of the regulatory base for technical requirements and test methods for delivery fire hoses. Series: Engineering Science and Architecture, 154, 312–317. doi: https://doi.org/10.33042/2522-1809-2020-1-154-312-317

- Muramatsu, H., Iino, R., Yoneda, K. (2018). Development of Fire Hose Laying Robot. The Proceedings of JSME Annual Conference on Robotics and Mechatronics (Robomec), 2018, 1A1-I12. doi: https://doi.org/10.1299/jsmermd.2018.1a1-i12

- Stas, S., Bychenko, A., Kolesnikov, D., Myhalenko, O., Pustovit, M. (2021). Experimental study of changes in the geometric parameters of fire hoses during the supply of extinguishing agents. Bulletin of the National Technical University "KhPI". Ser.: Hydraulic Machines and Hydraulic Units, 2, 39–42. Available at: http://gm.khpi.edu.ua/article/view/248744

- Stas, S., Bychenko, A., Pustovit, M., Myhalenko, O., Kolesnikov, D. (2022). Experimental research of geometric parameters change of the of fire hoses when using the Protek 366 nozzle. Bulletin of the National Technical University "KhPI". Ser.: Hydraulic Machines and Hydraulic Units, 1, 78–82. Available at: http://gm.khpi.edu.ua/article/view/267053

- Kostiuk, D., Kolesnikov, D., Stas, S., Yakhno, O. (2018). Research into cavitation processes in the trapped volume of the gear pump. Eastern-European Journal of Enterprise Technologies, 4 (7 (94)), 61–66. doi: https://doi.org/10.15587/1729-4061.2018.139583

- Yakhno, O., Seminskaya, N., Kolesnikov, D., Stas, S. (2014). Destabilization of stream in a channel with the length-varying flow rate. Eastern-European Journal of Enterprise Technologies, 3 (7 (69)), 45–49. doi: https://doi.org/10.15587/1729-4061.2014.24658

- Yakhno, O., Stas, S., Gnativ, R. (2015). Taking into account the fluid compressibility at its unsteady flow in pressure pipelines of fire extinguishing systems. Eastern-European Journal of Enterprise Technologies, 3 (7 (75)), 38–42. doi: https://doi.org/10.15587/1729-4061.2015.42447

- Maglyovana, T., Nyzhnyk, T., Stas, S., Kolesnikov, D., Strikalenko, T. (2020). Improving the efficiency of water fire extinguishing systems operation by using guanidine polymers. Eastern-European Journal of Enterprise Technologies, 1 (10 (103)), 20–25. doi: https://doi.org/10.15587/1729-4061.2020.196881

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Serhiy Stas, Artem Bychenko, Denis Kolesnikov, Oleksii Myhalenko, Mykhailo Pustovit, Kostiantyn Myhalenko, Lesya Horenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.