Designing engobe coatings for ceramic bricks

DOI:

https://doi.org/10.15587/1729-4061.2023.279918Keywords:

engobe, rheological properties, ceramic brick, thermal expansion, crystal phase, shrinkageAbstract

This paper reports research into the development of compositions of engobe coatings for ceramic bricks and investigating the influence of technological production factors on their physical and mechanical properties. The results of this work make it possible to solve the task of expanding the range and improving the operational properties of building ceramics.

The data obtained have made it possible to establish physicochemical processes occurring during the formation of the phase composition and structure of engobe coatings. This has revealed the possibilities for designing engobe for various types of ceramic bricks, which differ in technological parameters of production and operational properties.

The charge compositions were designed in a three-component system "refractory clay – quartz sand – cullet", taking into account the possibility of their practical implementation in large-tonnage production. It has been established that the most important condition for obtaining high-quality products is the correlation of shrinkage and temperature coefficients of linear expansion of the ceramic shard and engobe coating. To prevent various defects, these indicators should vary by no more than 10 %.

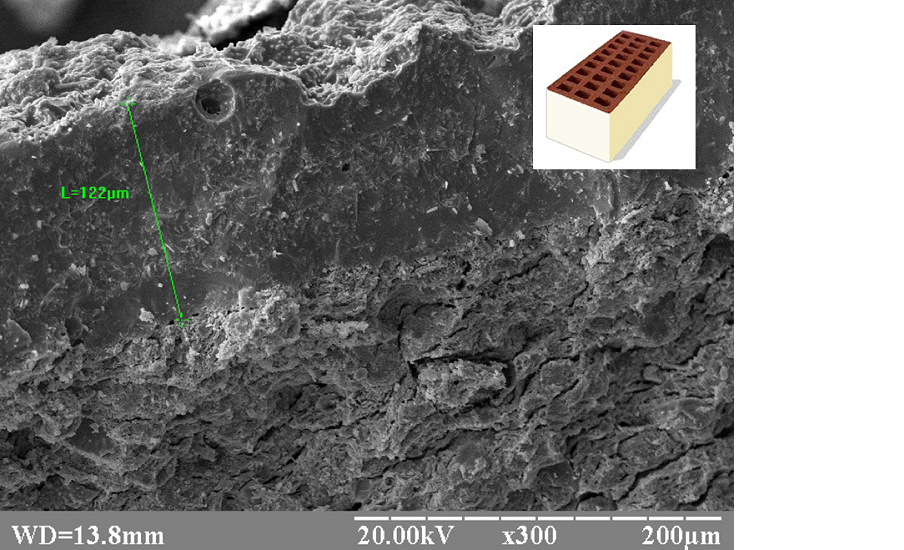

The crystal-phase composition of engobe is represented by b-quartz and a small amount of devitrite, which are evenly distributed in a vitreous dense layer of coating on the surface of the ceramic shard.

Distinctive features of the results relate to the fact that a solution to the problem of designing engobe coatings for ceramic bricks has been proposed and the physicochemical bases of production have been highlighted. This paper also suggests ways to achieve coordination of finely dispersed coatings with coarse-grained ceramic masses by shrinkage and thermal processes.

The results reported here could be applied in typical production of face, clinker, and in some cases – ordinary brick or ceramic stone with firing temperatures of 950–1150 °C

References

- Muneron, L. M., Hammad, A. W., Najjar, M. K., Haddad, A., Vazquez, E. G. (2021). Comparison of the environmental performance of ceramic brick and concrete blocks in the vertical seals' subsystem in residential buildings using life cycle assessment. Cleaner Engineering and Technology, 5, 100243. doi: https://doi.org/10.1016/j.clet.2021.100243

- Khomenko, О. S., Datsenko, B. M., Fomenko, G. V. (2022). Determination of approaches to the development of ceramic compositions for the manufacture of facial bricks. Voprosy Khimii i Khimicheskoi Tekhnologii, 6, 98–107. doi: https://doi.org/10.32434/0321-4095-2022-145-6-98-107

- Pavlova, I. A., Sapozhnikova, M., Farafontova, E. P. (2020). The Effect of Manganese-Containing Pigment on the Strength of Ceramic Bricks. Materials Science Forum, 989, 329–334. doi: https://doi.org/10.4028/www.scientific.net/msf.989.329

- Khomenko, O., Datsenko, B., Sribniak, N., Nahornyi, M., Tsyhanenko, L. (2019). Development of engobe coatings based on alkaline kaolins. Eastern-European Journal of Enterprise Technologies, 6 (6 (102)), 49–56. doi: https://doi.org/10.15587/1729-4061.2019.188126

- Mangone, A., Caggiani, M. C., Giannossa, L. C., Eramo, G., Redavid, V., Laviano, R. (2013). Diversified production of red figured pottery in Apulia (Southern Italy) in the late period. Journal of Cultural Heritage, 14 (1), 82–88. doi: https://doi.org/10.1016/j.culher.2012.03.011

- Dal Bó, M., Bernardin, A. M., Hotza, D. (2014). Formulation of ceramic engobes with recycled glass using mixture design. Journal of Cleaner Production, 69, 243–249. doi: https://doi.org/10.1016/j.jclepro.2014.01.088

- Jaramillo Nieves, L. J., Nastri, S., Lot, A. V., Melchiades, F. G., Marsola, G. A., Flauzino, I. S. et al. (2022). Influence of engobe and glaze layers on the evolution of porosity and permeability of single-fired porcelain tiles. Applied Clay Science, 228, 106635. doi: https://doi.org/10.1016/j.clay.2022.106635

- Kavanova, M., Kloužková, A., Kloužek, J. (2017). Characterization of the interaction between glazes and ceramic bodies. Ceramics – Silikaty, 61 (1), 267–275. doi: https://doi.org/10.13168/cs.2017.0025

- Nandi, V. S., Raupp-Pereira, F., Montedo, O. R. K., Oliveira, A. P. N. (2015). The use of ceramic sludge and recycled glass to obtain engobes for manufacturing ceramic tiles. Journal of Cleaner Production, 86, 461–470. doi: https://doi.org/10.1016/j.jclepro.2014.08.091

- Tarhan, M., Tarhan, B. (2019). Development of waterproof engobe layer for ceramic wall tiles. Journal of Thermal Analysis and Calorimetry, 140 (2), 555–565. doi: https://doi.org/10.1007/s10973-019-08893-3

- Samoilenko, N., Shchukina, L., Baranova, A. (2019). Development of engobe composition with the use of pharmaceutical glass waste for glazed ceramic granite. Eastern-European Journal of Enterprise Technologies, 4 (10 (100)), 6–12. doi: https://doi.org/10.15587/1729-4061.2019.175922

- Koleda, V. V., Mikhailyuta, E. S., Alekseev, E. V., Tsybul’ko, É. S. (2009). Technological particularities of clinker brick production. Glass and Ceramics, 66 (3-4), 132–135. doi: https://doi.org/10.1007/s10717-009-9129-3

- Subashi De Silva, G. H. M. J., Hansamali, E. (2019). Eco-friendly fired clay bricks incorporated with porcelain ceramic sludge. Construction and Building Materials, 228, 116754. doi: https://doi.org/10.1016/j.conbuildmat.2019.116754

- Benahsina, A., El Haloui, Y., Taha, Y., Elomari, M., Bennouna, M. A. (2022). Substitution of natural clay by Moroccan solid mining wastes to manufacture fired bricks. Materials Today: Proceedings, 58, 1324–1330. doi: https://doi.org/10.1016/j.matpr.2022.02.211

- Luangnaem, C., Sathonsaowaphak, A., Kamon-In, O., Pimraksa, K. (2014). Development of Engobe Samples for Dan Kwian Ceramic Body. Key Engineering Materials, 608, 325–330. doi: https://doi.org/10.4028/www.scientific.net/kem.608.325

- Johnson, L. A., McCauley, R. A. (2005). The thermal behavior of albite as observed by DTA. Thermochimica Acta, 437 (1-2), 134–139. doi: https://doi.org/10.1016/j.tca.2005.06.039

- Governatori, M., Cedillo-González, E.I., Manfredini, T., Siligardi, C. (2022). Solar reflective properties of porcelain tiles for UHI mitigation: effect of highly reflective frits in the engobe's formulation. Materials Today Sustainability, 20, 100255. doi: https://doi.org/10.1016/j.mtsust.2022.100255

- Ferrari, C., Muscio, A., Siligardi, C. (2016). Development of a Solar-reflective Ceramic Tile Ready for Industrialization. Procedia Engineering, 169, 400–407. doi: https://doi.org/10.1016/j.proeng.2016.10.049

- Zorigt, S., Jadamba, Ts., Tsevel, S. (2012). Synthesis and structural studies of face engobe layer's mass. Proceedings 7th International Forum on Strategic Technology, IFOST. doi: https://doi.org/10.1109/ifost.2012.6357603

- Yatsenko, N. D., Rat’kova, É. O. (2009). Engobes for ceramic brick. Glass and Ceramics, 66 (3-4), 93–94. doi: https://doi.org/10.1007/s10717-009-9144-4

- Janus, M., Zając, K. (2019). Self-cleaning efficiency of nanoparticles applied on facade bricks. Nanotechnology in Eco-Efficient Construction, 591–618. doi: https://doi.org/10.1016/b978-0-08-102641-0.00024-4

- Becker, E., Jiusti, J., Minatto, F. D., Delavi, D. G. G., Montedo, O. R. K., Noni Jr., A. de. (2017). Use of mechanically-activated kaolin to replace ball clay in engobe for a ceramic tile. Cerâmica, 63 (367), 295–302. doi: https://doi.org/10.1590/0366-69132017633672077

- Bernasconi, A., Diella, V., Pagani, A., Pavese, A., Francescon, F., Young, K. et al. (2011). The role of firing temperature, firing time and quartz grain size on phase-formation, thermal dilatation and water absorption in sanitary-ware vitreous bodies. Journal of the European Ceramic Society, 31 (8), 1353–1360. doi: https://doi.org/10.1016/j.jeurceramsoc.2011.02.006

- Gültekin, E. E., Topateş, G., Kurama, S. (2017). The effects of sintering temperature on phase and pore evolution in porcelain tiles. Ceramics International, 43 (14), 11511–11515. doi: https://doi.org/10.1016/j.ceramint.2017.06.024

- Shaikh, S. M. R., Nasser, M. S., Hussein, I., Benamor, A., Onaizi, S. A., Qiblawey, H. (2017). Influence of polyelectrolytes and other polymer complexes on the flocculation and rheological behaviors of clay minerals: A comprehensive review. Separation and Purification Technology, 187, 137–161. doi: https://doi.org/10.1016/j.seppur.2017.06.050

- Khomenko, O. S. (2018). Choice of ceramic masses for the manufacture of electrical ceramics. Voprosy Khimii i Khimicheskoi Tekhnologii, 1, 92–95. Available at: http://vhht.dp.ua/wp-content/uploads/pdf/2018/1/Khomenko.pdf

- Kavanova, M., Kloužková, A., Kloužek, J. (2017). Characterization of the interaction between glazes and ceramic bodies. Ceramics – Silikaty, 61 (1), 267–275. doi: https://doi.org/10.13168/cs.2017.0025

- Venturelli, C., Paganelli, M. (2006). Thermo-mechanical behaviour of technical ceramic bricks, felt boards and fibres. CFI Ceramic Forum International, 83, 4, E18–E22. Available at: https://www.expertlabservice.it/en/publication/thermo-mechanical-behaviour-of-technical-ceramic-bricks-felt-boards-and-fibres/

- Goncalves, R. A., Dal-Pont, G., Werneke, A. S. W. Riella, H. G., Mamede, W. F. (2000). Determination of mohs hardness of glazed tiles by scratching tests. Ceramic Technology Center, 67–71. Available at: https://www.qualicer.org/recopilatorio/ponencias/pdfs/0032170e.pdf

- Li, J., Lin, H., Li, J., Wu, J. (2009). Effects of different potassium salts on the formation of mullite as the only crystal phase in kaolinite. Journal of the European Ceramic Society, 29 (14), 2929–2936. doi: https://doi.org/10.1016/j.jeurceramsoc.2009.04.032

- Kazmina, O. V., Tokareva, A. Y., Vereshchagin, V. I. (2016). Using quartzofeldspathic waste to obtain foamed glass material. Resource-Efficient Technologies, 2 (1), 23–29. doi: https://doi.org/10.1016/j.reffit.2016.05.001

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Olena Khomenko, Liudmyla Tsyhanenko, Hennadii Tsyhanenko, Artem Borodai, Dmytro Borodai, Serhii Borodai

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.