Development of informational-technological support for designing cutting diagrams of haberdashery parts

DOI:

https://doi.org/10.15587/1729-4061.2023.281426Keywords:

rational cutting, cutting schemes, haberdasheryAbstract

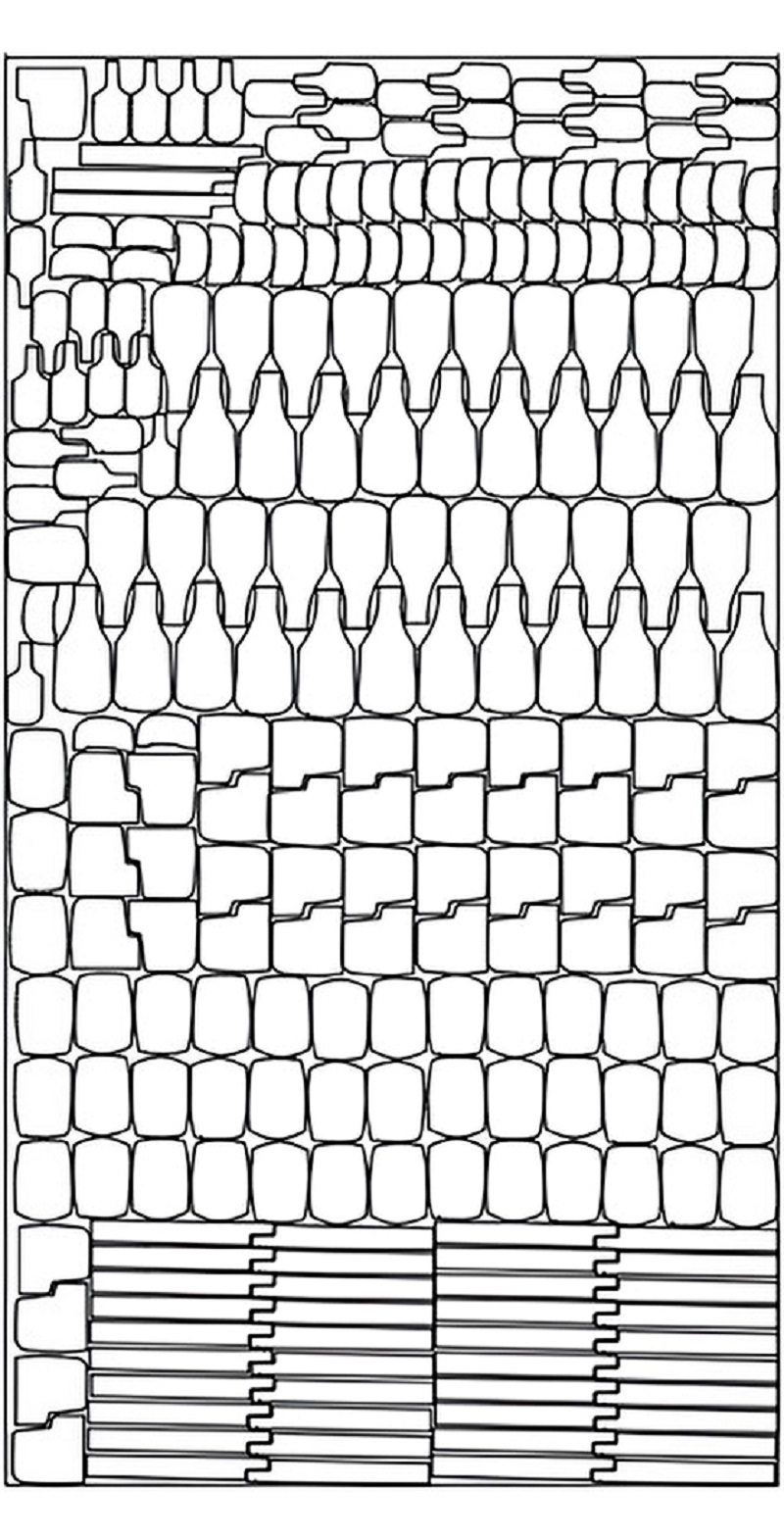

The object of research is the technological process of cutting rectangular materials into haberdashery parts.

The mathematical statement of the problem to find cutting diagrams of rectangular materials for haberdashery parts is given. The structural components of this problem and its mathematical model were described.

A method for implementing the task set is proposed, which includes the following stages:

– generation of layouts;

– generation of a set of permissible sections of one part, from a combination of two parts, and from a combination of three product parts;

– generation of cutting diagrams of rectangular materials for haberdashery parts from a combination of designed sections.

Implementation algorithms have been proposed for each of the stages of the task. The proposed algorithms were used in the development of information technology support for finding cutting diagrams of rectangular materials for haberdashery parts.

The information and technological support that was offered makes it possible to create graphic visualizations of rational cutting schemes and save them in a file. This feature allows automated cutting systems to use information about such schemes.

The developed information technology support was tested on the parts of haberdashery and showed its effectiveness. This information and technological support can be successfully used at haberdashery enterprises in preparatory and cutting production to increase the utilization of material during cutting by 1.5–2.5 %.

Thus, the proposed information and technological support makes it possible to improve the technological process of designing rational schemes of cutting for haberdashery articles

References

- Cinat, P., Gnecco, G., Paggi, M. (2020). Multi-Scale Surface Roughness Optimization Through Genetic Algorithms. Frontiers in Mechanical Engineering, 6. doi: https://doi.org/10.3389/fmech.2020.00029

- Mundim, L. R., Andretta, M., Carravilla, M. A., Oliveira, J. F. (2017). A general heuristic for two-dimensional nesting problems with limited-size containers. International Journal of Production Research, 56 (1-2), 709–732. doi: https://doi.org/10.1080/00207543.2017.1394598

- Leao, A. A. S., Toledo, F. M. B., Oliveira, J. F., Carravilla, M. A. (2015). A semi-continuous MIP model for the irregular strip packing problem. International Journal of Production Research, 54 (3), 712–721. doi: https://doi.org/10.1080/00207543.2015.1041571

- Leao, A. A. S., Toledo, F. M. B., Oliveira, J. F., Carravilla, M. A., Alvarez-Valdés, R. (2020). Irregular packing problems: A review of mathematical models. European Journal of Operational Research, 282 (3), 803–822. doi: https://doi.org/10.1016/j.ejor.2019.04.045

- Liu, X., Liu, J., Cao, A., Yao, Z. (2015). HAPE3D—a new constructive algorithm for the 3D irregular packing problem. Frontiers of Information Technology & Electronic Engineering, 16 (5), 380–390. doi: https://doi.org/10.1631/fitee.1400421

- Cherri, L. H., Cherri, A. C., Soler, E. M. (2018). Mixed integer quadratically-constrained programming model to solve the irregular strip packing problem with continuous rotations. Journal of Global Optimization, 72 (1), 89–107. doi: https://doi.org/10.1007/s10898-018-0638-x

- Peralta, J., Andretta, M., Oliveira, J. F. (2018). Solving irregular strip packing problems with free rotations using separation lines. Pesquisa Operacional, 38 (2), 195–214. doi: https://doi.org/10.1590/0101-7438.2018.038.02.0195

- Stoyan, Y., Pankratov, A., Romanova, T. (2016). Cutting and packing problems for irregular objects with continuous rotations: mathematical modelling and non-linear optimization. Journal of the Operational Research Society, 67 (5), 786–800. doi: https://doi.org/10.1057/jors.2015.94

- Wang, A., Hanselman, C. L., Gounaris, C. E. (2018). A customized branch-and-bound approach for irregular shape nesting. Journal of Global Optimization, 71 (4), 935–955. doi: https://doi.org/10.1007/s10898-018-0637-y

- Guo, B., Ji, Y., Hu, J., Wu, F., Peng, Q. (2019). Efficient Free-Form Contour Packing Based on Code Matching Strategy. IEEE Access, 7, 57917–57926. doi: https://doi.org/10.1109/access.2019.2914248

- Ke, Q., Zhang, P., Zhang, L., Song, S. (2020). Electric Vehicle Battery Disassembly Sequence Planning Based on Frame-Subgroup Structure Combined with Genetic Algorithm. Frontiers in Mechanical Engineering, 6. doi: https://doi.org/10.3389/fmech.2020.576642

- Hopcroft, J. E., Motwani, R., Ullman, J. D. (2001). Introduction to Automata Theory, Languages, and Computation. Boston: Addison-Wesley. Available at: https://archive.org/details/introductiontoau00hopc_510

- Havrylov, T. M., Chuprynka, V. I. (2011). Model avtomatychnoho proektuvannia skhem rozkroiu lystovykh materialiv na detali vzuttia. Visnyk KNUTD, 6, 83–88. Available at: https://knutd.edu.ua/files/Visnyk/Visnuk_6_2011.pdf

- Chuprynka, V. I., Murzhenko, V. S. (2011). Metod avtomatyzovanoho proektuvannia shchilnykh ukladok pry priamokutno-hnizdoviy skhemi rozkroiu. Visnyk KNUTD, 6, 72–77. Available at: https://knutd.edu.ua/files/Visnyk/Visnuk_6_2011.pdf

- Chuprynka, V. I., Naumenko, B. V., Vasylenko, O. L. (2022). Heneruvannia ratsionalnykh skhem rozkroiu rulonnykh materialiv na detali shkirhalanterei. Mekhatronni systemy: innovatsiyi ta inzhynirynhtezy dopovidei VI mizhnar. Nauk.-prakt. konf. Kyiv: KNUTD, 157–158. Available at: https://er.knutd.edu.ua/bitstream/123456789/20956/1/MSIE_2022_P157-158.pdf

- Kolysko, O. Z. (2009). Modyfikatsiya henetychnoho alhorytmu dlia heneratsiyi sektsiy rozkriinykh skhem. Visnyk KNUTD, 1, 54–56. Available at: https://er.knutd.edu.ua/bitstream/123456789/6983/1/V45_P014-017.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Viktor Chuprynka, Tetiana Demkivska, Nataliia Chuprynka, Ievgen Demkivskyi, Bohdan Naumenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.