The implementation of fusion properties calculation to predict wax deposition

DOI:

https://doi.org/10.15587/1729-4061.2023.281657Keywords:

fusion properties, melting point temperature, solid state temperature, wax depositionAbstract

Deposition of wax on the pipe walls is one of the complex flow assurance problems that causes a decrease and complete blockage of oil production rates by reducing the cross-sectional area of flow in the pipelines. In addition, surface facilities require higher energy consumption and failure of facilities due to wax plugging.

Effective design of oil recovery processes requires an adequate prediction of the thermodynamic conditions in which wax can precipitate from crude oil, depending on the pressure, temperature, and composition of the oil.

In this paper, the modified melting and pour point temperatures were presented based on the fluid description. Other fusion properties such as the enthalpy of fusion, the solid-state transition enthalpies, and the heat capacity of fusion have been calculated to modify the multi-solid model for predicting wax deposition.

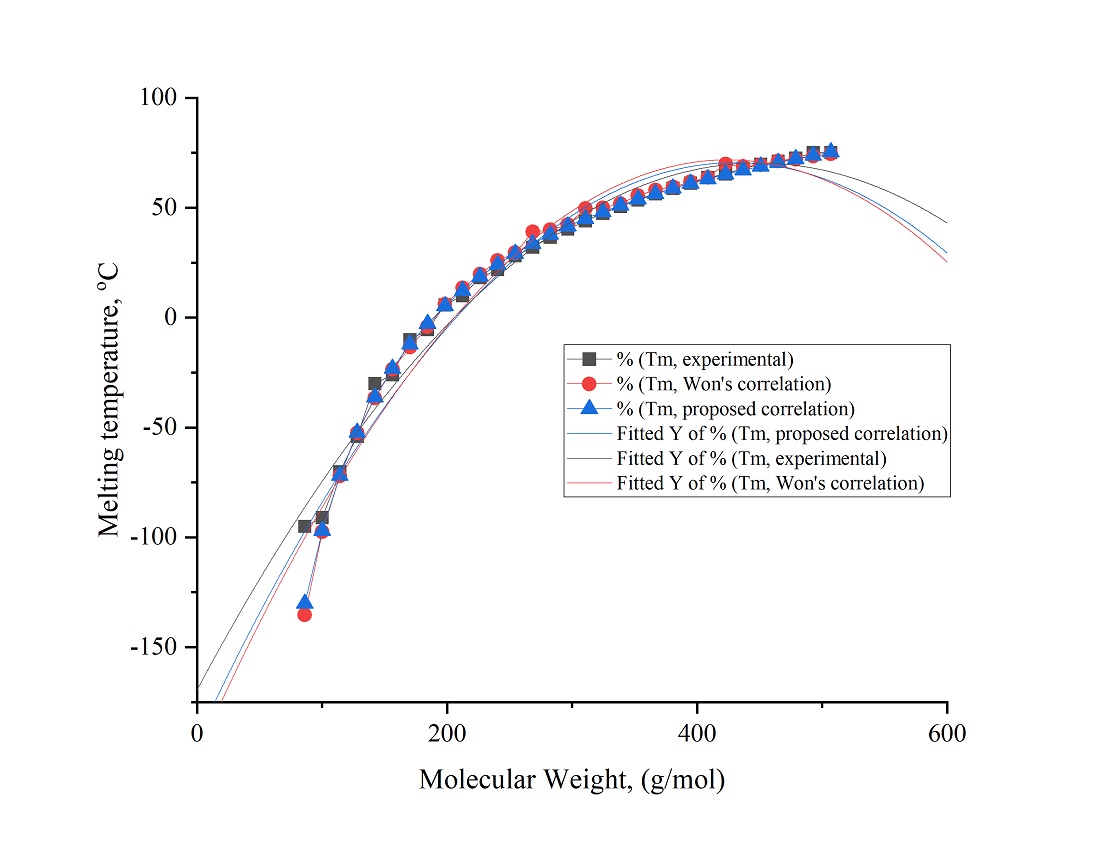

The proposed modified equations for melting and pour point temperatures were showing reliable agreement with experimental data based on SARA analysis and demonstrated more accurate results compare to literature data.

In order to justify the proposed model, the comparative approach has been implemented between literature, experimental, and data obtained based on proposed solutions.

The detailed description of the Republic of Kazakhstan’s (RoK) oil fields, components from C1 up to C36+ has been used during this research and the most crucial components which tend to form wax precipitation from C15H32 to C20H42 were plotted, which showed an increasing accuracy of 11 % for melting point temperature and 7 % for pour point temperature compared to literature data.

As a result, the proposed modified solutions for fusion properties demonstrated good agreement with literature and obtained results of modifications can be used for further research on Multi solid model of wax precipitation

References

- Lei, Y., Han, S., Zhang, J. (2016). Effect of the dispersion degree of asphaltene on wax deposition in crude oil under static conditions. Fuel Processing Technology, 146, 20–28. doi: https://doi.org/10.1016/j.fuproc.2016.02.005

- Hao, L. Z. et al. (2019). A Review of the Mechanism and Role of Wax Inhibitors in the Wax Deposition and Precipitation. Pertanika Journal of Science & Technology 27 (1). Available at: http://www.pertanika.upm.edu.my/resources/files/Pertanika%20PAPERS/JST%20Vol.%2027%20(1)%20Jan.%202019/29%20JST-1110-2018.pdf

- Lim, Z. H., Al Salim, H. S., Ridzuan, N., Nguele, R., Sasaki, K. (2018). Effect of surfactants and their blend with silica nanoparticles on wax deposition in a Malaysian crude oil. Petroleum Science, 15 (3), 577–590. doi: https://doi.org/10.1007/s12182-018-0241-2

- Won, K. W. (1986). Thermodynamics for solid solution-liquid-vapor equilibria: wax phase formation from heavy hydrocarbon mixtures. Fluid Phase Equilibria, 30, 265–279. doi: https://doi.org/10.1016/0378-3812(86)80061-9

- Hansen, J. H., Fredenslund, Aa., Pedersen, K. S., Rønningsen, H. P. (1988). A thermodynamic model for predicting wax formation in crude oils. AIChE Journal, 34 (12), 1937–1942. doi: https://doi.org/10.1002/aic.690341202

- Won, K. W. (1989). Thermodynamic calculation of cloud point temperatures and wax phase compositions of refined hydrocarbon mixtures. Fluid Phase Equilibria, 53, 377–396. doi: https://doi.org/10.1016/0378-3812(89)80104-9

- Schou Pedersen, K., Skovborg, P., Roenningsen, H. P. (1991). Wax precipitation from North Sea crude oils. 4. Thermodynamic modeling. Energy & Fuels, 5 (6), 924–932. doi: https://doi.org/10.1021/ef00030a022

- Lira-Galeana, C., Firoozabadi, A., Prausnitz, J. M. (1996). Thermodynamics of wax precipitation in petroleum mixtures. AIChE Journal, 42 (1), 239–248. doi: https://doi.org/10.1002/aic.690420120

- Pan, H., Firoozabadi, A., Fotland, P. (1997). Pressure and Composition Effect on Wax Precipitation: Experimental Data and Model Results. SPE Production & Facilities, 12 (04), 250–258. doi: https://doi.org/10.2118/36740-pa

- Nichita, D. V., Goual, L., Firoozabadi, A. (2001). Wax Precipitation in Gas Condensate Mixtures. SPE Production & Facilities, 16 (04), 250–259. doi: https://doi.org/10.2118/74686-pa

- Escobar-Remolina, J. C. M. (2006). Prediction of characteristics of wax precipitation in synthetic mixtures and fluids of petroleum: A new model. Fluid Phase Equilibria, 240 (2), 197–203. doi: https://doi.org/10.1016/j.fluid.2005.12.033

- Riazi, M. (Ed.) (2005). Characterization and Properties of Petroleum Fractions. ASTM International. doi: https://doi.org/10.1520/mnl50_1st-eb

- Mansourpoor, M., Azin, R., Osfouri, S., Izadpanah, A. A. (2018). Study of wax disappearance temperature using multi-solid thermodynamic model. Journal of Petroleum Exploration and Production Technology, 9 (1), 437–448. doi: https://doi.org/10.1007/s13202-018-0480-1

- Chen, W., Zhao, Z., Zhang, X., Wang, L. (2007). Thermodynamic phase equilibria of wax precipitation in crude oils. Fluid Phase Equilibria, 255 (1), 31–36. doi: https://doi.org/10.1016/j.fluid.2007.03.015

- Coutinho, J. A. P., Mirante, F., Pauly, J. (2006). A new predictive UNIQUAC for modeling of wax formation in hydrocarbon fluids. Fluid Phase Equilibria, 247 (1-2), 8–17. doi: https://doi.org/10.1021/ie980340h

- Soedarmo, A. A., Daraboina, N., Sarica, C. (2017). Validation of wax deposition models with recent laboratory scale flow loop experimental data. Journal of Petroleum Science and Engineering, 149, 351–366. doi: https://doi.org/10.1016/j.petrol.2016.10.017

- van der Geest, C., Melchuna, A., Bizarre, L., Bannwart, A. C., Guersoni, V. C. B. (2021). Critical review on wax deposition in single-phase flow. Fuel, 293, 120358. doi: https://doi.org/10.1016/j.fuel.2021.120358

- Sousa, A. M., Matos, H. A., Pereira, M. J. (2019). Modelling Paraffin Wax Deposition Using Aspen HYSYS and MATLAB. 29th European Symposium on Computer Aided Process Engineering, 973–978. doi: https://doi.org/10.1016/b978-0-12-818634-3.50163-6

- Jafari Behbahani, T. (2016). Experimental study and a proposed new approach for thermodynamic modeling of wax precipitation in crude oil using a PC-SAFT model. Petroleum Science, 13 (1), 155–166. doi: https://doi.org/10.1007/s12182-015-0071-4

- Asbaghi, E. V., Assareh, M. (2021). Application of a sequential multi-solid-liquid equilibrium approach using PC-SAFT for accurate estimation of wax formation. Fuel, 284, 119010. doi: https://doi.org/10.1016/j.fuel.2020.119010

- Asbaghi, E. V., Nazari, F., Assareh, M., Nezhad, M. M. (2022). Toward an efficient wax precipitation model: Application of multi-solid framework and PC-SAFT with focus on heavy end characterization for different crude types. Fuel, 310, 122205. doi: https://doi.org/10.1016/j.fuel.2021.122205

- Yang, J., Lu, Y., Daraboina, N., Sarica, C. (2020). Wax deposition mechanisms: Is the current description sufficient? Fuel, 275, 117937. doi: https://doi.org/10.1016/j.fuel.2020.117937

- Alnaimat, F., Ziauddin, M. (2020). Wax deposition and prediction in petroleum pipelines. Journal of Petroleum Science and Engineering, 184, 106385. doi: https://doi.org/10.1016/j.petrol.2019.106385

- Yao, B., Zhao, D., Zhang, Z., Huang, C. (2021). Safety Study on Wax Deposition in Crude Oil Pipeline. Processes, 9 (9), 1572. doi: https://doi.org/10.3390/pr9091572

- Hu, Z., Meng, D., Liu, Y., Dai, Z., Jiang, N., Zhuang, Z. (2019). Study of wax deposition law by cold finger device. Petroleum Science and Technology, 37 (15), 1846–1853. doi: https://doi.org/10.1080/10916466.2019.1613431

- Yang, T., Fevang, Ø., Christoffersen, K., Ivarrud, E. (2007). LBC Viscosity Modeling of Gas Condensate to Heavy Oil. All Days. doi: https://doi.org/10.2118/109892-ms

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Jamilyam Ismailova, Aibek Abdukarimov, Arman Kabdushev, Bakhytzhan Taubayev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.