Development of a localized production model for the automotive industry, built into the concept of industry 4.0 in the kingdom of Saudi Arabia

DOI:

https://doi.org/10.15587/1729-4061.2023.282297Keywords:

Localized Manufacturing, Industry 4.0, Saudi Arabia Auto Industry, Automotive Spare PartsAbstract

Saudi Arabia vision-2030 is mainly focused on industrialization to reduce reliance on oil revenue. Localized Manufacturing (LM) concept, which has gained its importance worldwide in this fast-changing technological world to meet customers’ unique needs of 21st century. Now-a-days, manufacturing industry is shifting from standard product development to customized product development keeping in view the growing unique customer-’s needs. The research objective of this research was to maximize LM Application in the Kingdom of Saudi Arabia to meet unique customers’ needs.

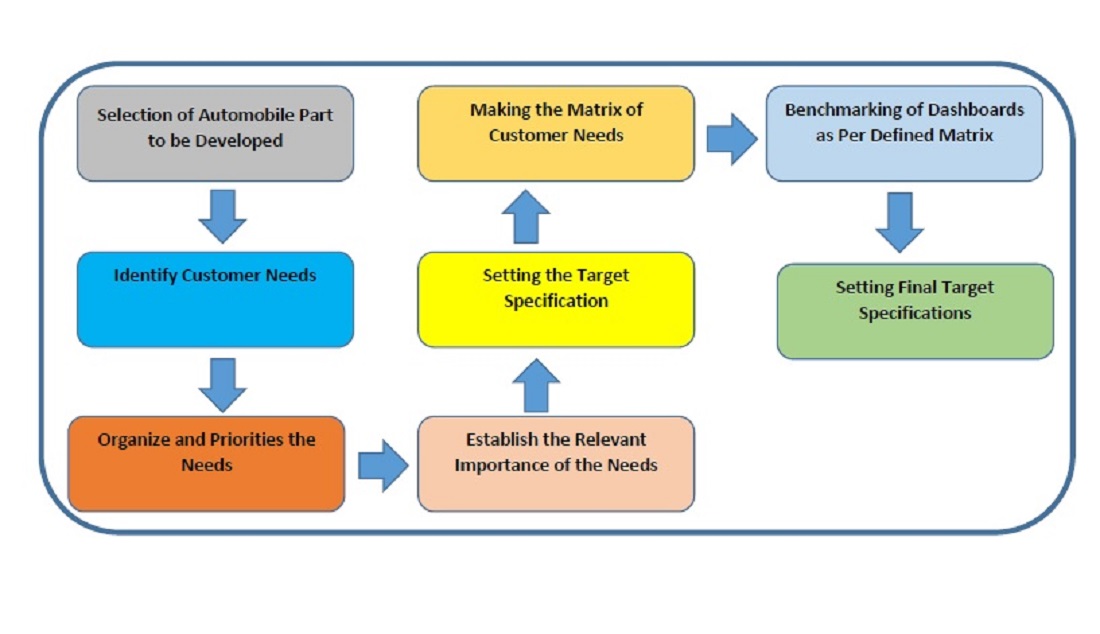

Automobile industry was selected to apply Industry 4.0 technologies i.e., 3D Printing/Additive manufacturing. The specifications, fulfilling the customer’s unique needs have been incorporated to manufacture the desired part by 3D printing/additive manufacturing. Data was collected from Saudi automobiles customers regarding their unique needs on a particular automobile part. Using the Product Design and Development methodology by Ulrich et al data was collected, analysed and as a result of data analysis, a model for maximization of localized manufacturing was developed for implementation of LM technique. Results shows that using Industry 4.0 concept, customers’ unique needs can be satisfied and fulfilled in less time and it will be more economical as compared to standard/conventional manufacturing/production methods. Based on the results of this research a model for maximization of localized manufacturing is developed utilizing Industry 4.0 technique

References

- Saad, S. M., Bahadori, R., Bhovar, C., Zhang, H. (2023). Industry 4.0 and Lean Manufacturing – a systematic review of the state-of-the-art literature and key recommendations for future research. International Journal of Lean Six Sigma. doi: https://doi.org/10.1108/ijlss-02-2022-0021

- van der Kley, D. (2020). Chinese Companies’ Localization in Kyrgyzstan and Tajikistan. Problems of Post-Communism, 67 (3), 241–250. doi: https://doi.org/10.1080/10758216.2020.1755314

- Liu, J., Liu, G., Cui, H., Chen, Y. (2023). The Chinese automobile industry’s research and development capability and innovative performance. Frontiers in Psychology, 13. doi: https://doi.org/10.3389/fpsyg.2022.1093305

- Auktor, G. V. (2022). The opportunities and challenges of Industry 4.0 for industrial development. A case study of Morocco’s automotive and garment sectors. Discussion Paper. Deutsches Institut für Entwicklungspolitik. Available at: https://www.idos-research.de/uploads/media/DP_2.2022.pdf

- Rezaeinejad, S. (2021). Automotive Industry and Its Place in the Economy: Case Study Iran Auto Industry. Asian Journal of Economics, Finance and Management, 5 (3), 23–32. doi: http://dx.doi.org/10.13140/RG.2.2.10019.17449

- Ambe, I., Badenhorst, W. J. (2011). South African automotive industry: trends and challenges in the supply chain. Journal of Contemporary Management, 8, 337–362.

- Ulrich, K. T., Steven, E. D., Maria, Y. C. (2020). Product Design and Development. McGraw Hill.

- Hofmann, E., Rüsch, M. (2017). Industry 4.0 and the current status as well as future prospects on logistics. Computers in Industry, 89, 23–34. doi: https://doi.org/10.1016/j.compind.2017.04.002

- Liao, Y., Deschamps, F., Loures, E. de F. R., Ramos, L. F. P. (2017). Past, present and future of Industry 4.0 - a systematic literature review and research agenda proposal. International Journal of Production Research, 55 (12), 3609–3629. doi: https://doi.org/10.1080/00207543.2017.1308576

- Gibson, I., Rosen, D., Stucker, B., Khorasani, M. (2020). Development of Additive Manufacturing Technology. Additive Manufacturing Technologies, 23–51. doi: https://doi.org/10.1007/978-3-030-56127-7_2

- Frank, A. G., Dalenogare, L. S., Ayala, N. F. (2019). Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economics, 210, 15–26. doi: https://doi.org/10.1016/j.ijpe.2019.01.004

- Kiel, D., Müller, J. M., Arnold, C., Voigt, K.-I. (2017). Sustainable industrial value creation: benefits and challenges of industry 4.0. International Journal of Innovation Management, 21 (08), 1740015. doi: https://doi.org/10.1142/s1363919617400151

- Elkality, S. A. H., Hassanein, W. S. A.-S. (2019). Using Industrial Engineering Tools in the Realization of Saudi Vision 2030 for Supporting Local Industry. Proceedings of the International Conference on Industrial Engineering and Operations Management Riyadh. Available at: http://www.ieomsociety.org/gcc2019/papers/5.pdf

- Rumzi Tausif, M., Imdadul Haque, M. (2018). Market dynamics and future prospects of the automobile industry in Saudi Arabia. Problems and Perspectives in Management, 16 (4), 246–258. doi: https://doi.org/10.21511/ppm.16(4).2018.21

- Tausif, M. R., Haque, M. I. (2019). Changing Market Scenario of Automobile Sector in Saudi Arabia. International Journal of Innovative Technology and Exploring Engineering, 8 (9), 1592–1598. doi: https://doi.org/10.35940/ijitee.h7189.078919

- Bessière, D., Charnley, F., Tiwari, A., Moreno, M. A. (2019). A vision of re-distributed manufacturing for the UK’s consumer goods industry. Production Planning & Control, 30 (7), 555–567. doi: https://doi.org/10.1080/09537287.2018.1540053

- Randheer, K., Trabulsi, H. U., Al Ajmi, H. A., Al Jasser, H. K. (2017). Emerging Industry: A Case of Automobile Manufacturing in Saudi Arabia. Journal of Marketing Research and Case Studies. doi: https://doi.org/10.5171/2017.799336

- Park, Y.-E. (2018). The Endless Challenges of KIA Motors for Globalization : A Case Study on Kia in Saudi Arabia. Journal of Industrial Distribution & Business, 9 (9), 45–52. doi: https://doi.org/10.13106/ijidb.2018.vol9.no9.45.

- Sweilam, M. N. (2018). Assessing Technological Capabilities in Arab Engineering Industries. Arab International Industrial Conference.4th International Conference of Engineering Division. Steps Towards Innovative Sustainable Development. Available at: https://www.academia.edu/36793139/Assessing_Technological_Capabilities_in_Arab_Engineering_Industries

- Yusuf, N., Nasrulddin, V. (2021). Employment Sustainability and Prospects of the Automotive Industry in Saudi Arabia. European Journal of Sustainable Development, 10 (3), 63. doi: https://doi.org/10.14207/ejsd.2021.v10n3p63

- Alnaser, H., Al-Madani, S. (2015). Understanding the dimensions of customer needs: The first step towards customer-driven manufacturing. International Journal of Business and Management, 10 (2), 92–102.

- Kar, S., Bag, S. (2014). Development of a metric for correlating customer needs with design solutions. International Journal of Industrial Engineering Computations, 5 (4), 627–640.

- Kazemzadeh, N., Kazemi, H., Ghazinoory, M. (2012). An approach to developing target specifications for new products: A case study. International Journal of Production Research, 50 (10), 2787–2803.

- Scott, J. W., Singh, B. Localized Manufacturing in the Automotive Industry: A Comparison of Mexico and South Africa.

- Heidenreich, S. (2009). Inter-organizational learning from benchmarking: Findings from the passenger airline industry. Long Range Planning, 42 (2), 262–282.

- Benchmarking: the search for industry best practices that lead to superior performance (1989). Choice Reviews Online, 27 (04), 27-2173-27–2173. doi: https://doi.org/10.5860/choice.27-2173

- Bailey, D., Clark, J., Colombelli, A., Corradini, C., De Propris, L., Derudder, B. et al. (2020). Regions in a time of pandemic. Regional Studies, 54 (9), 1163–1174. doi: https://doi.org/10.1080/00343404.2020.1798611

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Abdullah Awadh Aljuaid, Syed Athar Masood, Javed Ahmed Khan Tipu, Imran Shah

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.