Design of a multilink system for calculating high-frequency processes in electric machines with mesh windings

DOI:

https://doi.org/10.15587/1729-4061.2023.282375Keywords:

mesh windings, induction motors, defective insulation, frequency characteristics, high-frequency circuitAbstract

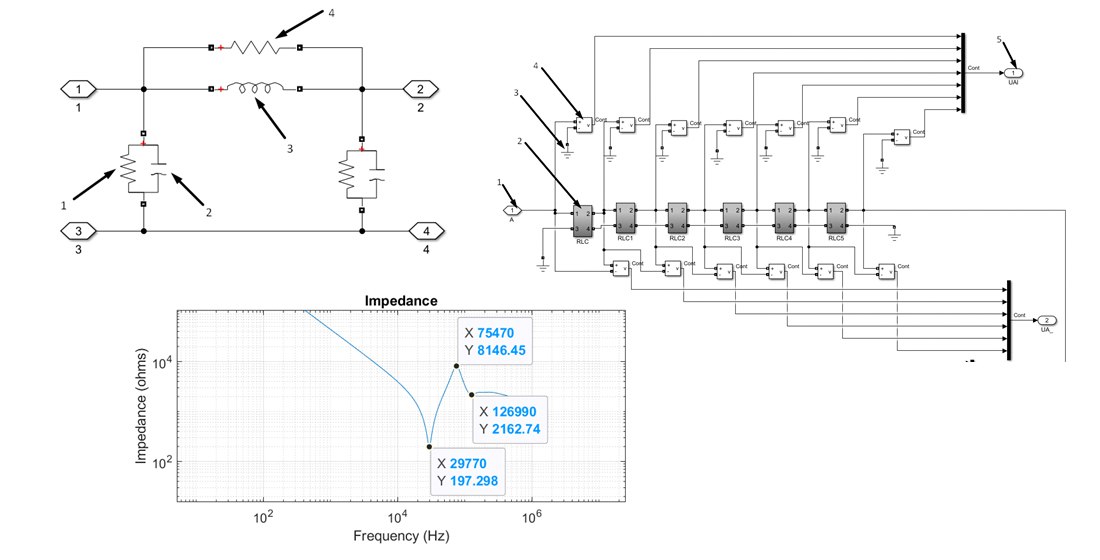

This study considers the design of a multi-link high-frequency circuit for calculating defective and defect-free insulation of mesh windings in order to increase the operational reliability of general-purpose electric machines.

The object of research is mesh windings of electric machines.

The problem to be solved: increasing the operational reliability of electric machines with general-purpose mesh windings by analyzing and modeling defects.

The research results make it possible to model defects for the analysis of the state of insulation of electric machines with mesh windings. Special attention in the research was paid to induction motors with a worn-out resource, in particular, 4A80A4 UZ engine. The analysis includes phase-to-body capacitance, winding inductance, eddy current impedance, and winding impedance.

Under the WN mode, a decrease in the impedance of the winding section from 3 % to the short-circuit mode was simulated; accordingly, the resonance frequencies for each case of 3 % were determined – 73990 Hz, short-circuit – 74450 Hz, as well as the corresponding input impedances 8938.7 and 8082.5. The corresponding voltage resonances and current resonances were also determined. Appropriate results were also given for the WG scheme.

The results reported here relate to the design of the scheme and the research on the defects of the mesh winding. This contributes to the analysis of the state of insulation of mesh windings. The numerical data (resonant frequencies and input impedances) allow a better understanding of the behavior of windings in different states and degrees of defects.

Given the research findings, it is possible to better identify and analyze potential defects in mesh windings, which in turn contributes to increasing the reliability of electric machines.

The results of this study could be used in the field of diagnosis, service, and maintenance of electric machines with mesh windings

References

- Hu, R., Wang, J., Mills, A. R., Chong, E., Sun, Z. (2021). Current-Residual-Based Stator Interturn Fault Detection in Permanent Magnet Machines. IEEE Transactions on Industrial Electronics, 68 (1), 59–69. doi: https://doi.org/10.1109/tie.2020.2965500

- Hu, R., Wang, J., Mills, A. R., Chong, E., Sun, Z. (2021). High-Frequency Voltage Injection Based Stator Interturn Fault Detection in Permanent Magnet Machines. IEEE Transactions on Power Electronics, 36 (1), 785–794. doi: https://doi.org/10.1109/tpel.2020.3005757

- Zorig, A., Hedayati Kia, S., Chouder, A., Rabhi, A. (2022). A comparative study for stator winding inter-turn short-circuit fault detection based on harmonic analysis of induction machine signatures. Mathematics and Computers in Simulation, 196, 273–288. doi: https://doi.org/10.1016/j.matcom.2022.01.019

- Naderi, P., Shiri, A. (2017). Rotor/Stator Inter-Turn Short Circuit Fault Detection for Saturable Wound-Rotor Induction Machine by Modified Magnetic Equivalent Circuit Approach. IEEE Transactions on Magnetics, 53 (7), 1–13. doi: https://doi.org/10.1109/tmag.2017.2672924

- Babaa, F., Bennis, O. (2021). An accurate inter-turn short circuit faults model dedicated to induction motors. International Journal of Electrical and Computer Engineering (IJECE), 11 (1), 9. doi: https://doi.org/10.11591/ijece.v11i1.pp9-16

- Yang, G., Li, S., Hussain, H., Zhang, J., Yang, J. (2023). A Novel SVPWM Fault-Tolerant Strategy for Torque Ripple Reduction of Seven-Phase Induction Machines Under Single-Phase Open-Circuit Fault. IEEE Transactions on Power Electronics, 38 (4), 5217–5229. doi: https://doi.org/10.1109/tpel.2022.3232122

- Xu, Z., Hu, C., Yang, F., Kuo, S.-H., Goh, C.-K., Gupta, A., Nadarajan, S. (2017). Data-Driven Inter-Turn Short Circuit Fault Detection in Induction Machines. IEEE Access, 5, 25055–25068. doi: https://doi.org/10.1109/access.2017.2764474

- Akhil Vinayak, B., Anjali Anand, K., Jagadanand, G. (2019). Wavelet‐based real‐time stator fault detection of inverter‐fed induction motor. IET Electric Power Applications, 14 (1), 82–90. doi: https://doi.org/10.1049/iet-epa.2019.0273

- Alalibo, B. P., Ji, B., Cao, W. (2022). Short Circuit and Broken Rotor Faults Severity Discrimination in Induction Machines Using Non-invasive Optical Fiber Technology. Energies, 15 (2), 577. doi: https://doi.org/10.3390/en15020577

- Cao, W., Alalibo, B. P., Ji, B., Chen, X., Hu, C. (2022). Optical FBG-T Based Fault Detection Technique for EV Induction Machines. Journal of Physics: Conference Series, 2195 (1), 012045. doi: https://doi.org/10.1088/1742-6596/2195/1/012045

- Ostroverkhov, M., Chumack, V., Falchenko, M., Kovalenko, M. (2022). Development of control algorithms for magnetoelectric generator with axial magnetic flux and double stator based on mathematical modeling. Eastern-European Journal of Enterprise Technologies, 6 (5 (120)), 6–17. doi: https://doi.org/10.15587/1729-4061.2022.267265

- Ostroverkhov, M., Chumack, V., Kovalenko, M., Kovalenko, I. (2022). Development of the control system for taking off the maximum power of an autonomous wind plant with a synchronous magnetoelectric generator. Eastern-European Journal of Enterprise Technologies, 4 (2 (118)), 67–78. doi: https://doi.org/10.15587/1729-4061.2022.263432

- Ostroverkhov, M., Chumack, V., Tymoshchuk, O., Kovalenko, M., Ihnatiuk, Y. (2022). Designing a voltage control system of the magnetoelectric generator with magnetic flux shunting for electric power systems. Eastern-European Journal of Enterprise Technologies, 5 (5 (119)), 16–25. doi: https://doi.org/10.15587/1729-4061.2022.265861

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vadim Chumack, Mykhailo Kovalenko, Oksana Tymoshchuk, Andrii Stulishenko, Yevhen Ihnatiuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.