Creation of a methodology for determining the moisture diffusion coefficient within vacuum drying of fruits

DOI:

https://doi.org/10.15587/1729-4061.2023.282389Keywords:

evaporation resistance coefficient, humidity, model with a moving boundary of the dry and wet state of the material, thermodynamic, water activityAbstract

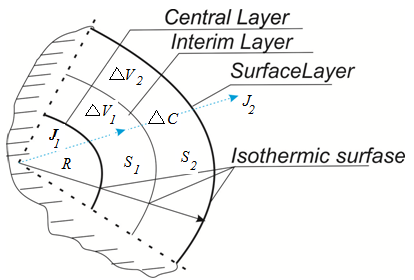

As the drying zone deepens, outer surface layer of the product does not have time to be moistened, due to a small amount of moisture coming from the inside. It becomes dry, its temperature rises. The intensity of moisture transfer from the inner layers of the product depends on many parameters, including a moisture diffusion coefficient. The study aim is to create a methodology for determining the moisture diffusion coefficient within vacuum drying of fruits, by taking into account cracks, channels and capillaries formed in the dry layer of the product through the resistance coefficient to evaporation. The work essence consists in the determining of the moisture diffusion coefficient as a driving force, a difference between water activity and air humidity, by considering the resistance coefficient to evaporation, characterizing the effect of hydrodynamic resistance of the dried dry layer of the product. This approach was used to determine the moisture diffusion coefficient during vacuum drying of the Baiterek apple sort and the Zhazdyk pear sort of Kazakhstani selection. It was established that in the first period of drying the moisture diffusion coefficient decreases on average from 24,4∙10‒7 m2/s to 13,2∙10‒7 m2/s. The critical humidity for pear is 37.4 %, and for apple 35.1 %. As result of the formation of dry layer on the surface and subsequent layers, the moisture diffusion coefficient gradually decreases. In the second drying period, the moisture diffusion coefficient decreases from 5,42∙10-8 m2/s to 2,12∙10‒8 m2/s. The work practical significance is related with the application of the obtained results in the determination of the optimal drying regime with maximum preservation of the product original quality. The proposed methodology can be used in the practice to study the moisture diffusion coefficient within vacuum drying of fruits, by considering the product properties and the hygroscopic parameters of the drying matter

References

- Shingisov, A., Alibekov, R., Evlash, V., Yerkebayeva, S., Mailybayeva, E., Tastemirova, U. (2023). Creation of a methodology for determining the intensity of moisture evaporation within vacuum drying of fruits. Eastern-European Journal of Enterprise Technologies, 1 (11 (121)), 6–14. doi: https://doi.org/10.15587/1729-4061.2023.273709

- Alibekov, R. S., Utebaeva, A. A., Nurseitova, Z. T., Konarbayeva, Z. K., Khamitova, B. M. (2021). Cottage cheese fortified by natural additives. Food Research, 5 (S1), 152–159. doi: https://doi.org/10.26656/fr.2017.5(s1).013

- Alibekov, R. S., Kaiypova, A. B., Urazbayeva, K. A., Ortayev, A. E., Azimov, A. M. (2019). Effect of substitution of sugar by high fructose corn syrup of the confiture on the base of physalis. Periódico Tchê Química, 16 (32), 688–697. doi: https://doi.org/10.52571/ptq.v16.n32.2019.706_periodico32_pgs_688_697.pdf

- Shingisov, A. U., Alibekov, R. S., Myrkhalykov, B. G., Musayeva, S. A., Urazbayeva, K. A., Iskakova, S. K. et al. (2016). Physicochemical Characteristics of the New Polyphyto-component Composition for Food Industry. Biosciences, Biotechnology Research Asia, 13 (2), 879–886. doi: https://doi.org/10.13005/bbra/2110

- Burova, N., Kislitsina, N., Gryazina, F., Pashkova, G., Kuzminykh, A. (2017). A review of techniques for drying food products in vacuum drying plants and methods for quality control of dried samples (Technical note). Revista Espacios, 38 (52). Available at: https://www.revistaespacios.com/a17v38n52/a17v38n52p35.pdf

- Liu, Y., Sabadash, S., Duan, Z., Deng, C. (2022). The influence of different drying methods on the quality attributes of beetroots. Eastern-European Journal of Enterprise Technologies, 3 (11 (117)), 60–68. doi: https://doi.org/10.15587/1729-4061.2022.258049

- Salehi, F., Aghajanzadeh, S. (2020). Effect of dried fruits and vegetables powder on cakes quality: A review. Trends in Food Science & Technology, 95, 162–172. doi: https://doi.org/10.1016/j.tifs.2019.11.011

- Abdizhapparova, B. T., Khanzharov, N. S., Ospanov, B. O., Pankina, I. A., Orymbetova, G. E. (2019). A way of vacuum-atmospheric drying of jerusalem artichoke tubers. NEWS of National Academy of Sciences of the Republic of Kazakhstan, 6 (438), 165–176. doi: https://doi.org/10.32014/2019.2518-170x.167

- Islam Shishir, M. R., Taip, F. S., Aziz, N. Ab., Talib, R. A., Hossain Sarker, Md. S. (2016). Optimization of spray drying parameters for pink guava powder using RSM. Food Science and Biotechnology, 25 (2), 461–468. doi: https://doi.org/10.1007/s10068-016-0064-0

- Shingisov, A. U., Mamaeva, L. A., Musaeva, S. A., Kozhabekova, G. A. (2017). Technology of production and application of polyphytocomponent in the food industry [Tehnologija proizvodstva i ispol'zovanija polifitokomponenta v pishhevoj promyshlennosti]. Almaty, 172.

- Ju, H.-Y., Zhang, Q., Mujumdar, A. S., Fang, X.-M., Xiao, H.-W., Gao, Z.-J. (2016). Hot-air Drying Kinetics of Yam Slices under Step Change in Relative Humidity. International Journal of Food Engineering, 12 (8), 783–792. doi: https://doi.org/10.1515/ijfe-2015-0340

- Millán-Merino, A., Fernández-Tarrazo, E., Sánchez-Sanz, M. (2021). Theoretical and numerical analysis of the evaporation of mono- and multicomponent single fuel droplets. Journal of Fluid Mechanics, 910. doi: https://doi.org/10.1017/jfm.2020.950

- Radojčin, M., Pavkov, I., Bursać Kovačević, D., Putnik, P., Wiktor, A., Stamenković, Z. et al. (2021). Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes, 9 (1), 132. doi: https://doi.org/10.3390/pr9010132

- Kondratyev, N. B., Kazancev, E. V., Osipov, M. V., Petrova, N. A., Rudenko, O. S. (2019). Research of the Moisture Transfer Processes in Gingerbread with Fruit Filling Produced using Various Types of Modified Starch. Storage and Processing of Farm Products, 4, 35–46. doi: https://doi.org/10.36107/spfp.2019.187

- Ponomarchuk, S. G., Salikova, A. A., Plaksen, N. V., Ustinova, L. V., Grigorchuk, V. P. (2022). Determination of the anthocyanine profile and optimal parameters of their extraction from Empetrum nigrum fruits. Pacific Medical Journal, 3, 75–80. doi: https://doi.org/10.34215/1609-1175-2022-3-75-80

- Korobka, S., Syrotyuk, S., Zhuravel, D., Boltianskyi, B., Boltianska, L. (2021). Solar Dryer with Integrated Energy Unit. Problems of the Regional Energetics, 2 (50). doi: https://doi.org/10.52254/1857-0070.2021.2-50.06

- Ermishina, E. Yu., Belokonova, N. A., Naronova, N. A., Borodulina, T. V. (2018). Definition of diffusion coefficients and dimensions of particles in restored dairy mixtures. Advances in current natural sciences, 4, 23–28. Available at: https://s.natural-sciences.ru/pdf/2018/4/36720.pdf

- Rizvi, S. (2005). Thermodynamic Properties of Foods in Dehydration. Food Science and Technology. doi: https://doi.org/10.1201/9781420028805.ch7

- Gurbanov, N., Gadimova, N., Osmanova, S., Ismailov, E., Akhundova, N. (2022). Chemical composition, thermal stability of pomegranate peel and seed powders and their application in food production. Eastern-European Journal of Enterprise Technologies, 6 (11 (120)), 24–33. doi: https://doi.org/10.15587/1729-4061.2022.268983

- Gurbanov, N., Yusifova, M., Tagiyev, M., Nasrullayeva, G., Kazimova, İ. (2023). Determining the qualitative parameters of powder from the stalks of garden purslane (Portulaca oleracea L.) and its application in the production of functional bakery products. Eastern-European Journal of Enterprise Technologies, 1 (11 (121)), 69–77. doi: https://doi.org/10.15587/1729-4061.2023.274202

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Azret Shingisov, Ravshanbek Alibekov, Victoriia Evlash, Saparkul Yerkebayeva, Elvira Mailybayeva, Ukilim Tastemirova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.