Strengthening of friction surfaces by using geomodifiers based on serpentines from the Dashukivka deposit

DOI:

https://doi.org/10.15587/1729-4061.2023.283441Keywords:

repair and restoration technologies, friction geomodifiers, serpentine, heavily loaded friction pairsAbstract

The object of research is the process of improving the tribological characteristics of friction joints, in particular anti-wear and anti-burr properties.

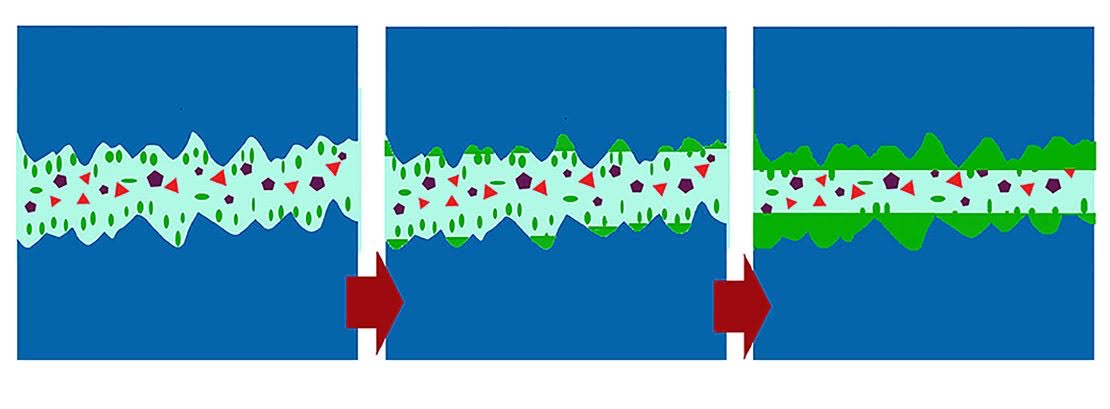

There is a practice of using serpentines, so-called "friction geomodifiers" (FGM), as special repair and restoration additives. Their use leads to a decrease in the coefficient of friction and temperatures in the contact zone; an increase in the mass of parts is observed, which indicates the restoration of worn surfaces. The mechanism of formation of new structures is still unclear. There are hypotheses that severe friction conditions initiate micrometallurgical processes at the atomic-crystalline level, as a result of which modified layers with unique tribological characteristics are formed on the surfaces.

A comparative analysis of the main indicators of serpentines of the Dashukivka deposit in terms of chemical composition and structure showed their correspondence to widely known analogs but they were never used in such a capacity.

According to the results of the tests, the additives have shown their effectiveness as geomodifiers of friction. Addition of 4 % serpentine to the lubricating composition based on I-20 A oil reduced the wear rate by 2–3 times, the friction moment by 15 %, compared to I-20 A without additives.

An increase in surface microhardness was observed, from 6 GPa for the basic variant to 10 GPa, for the variant with FGM additives.

It has been established that the use is most effective for heavily loaded friction pairs (ship fittings, hatch closures, etc.) as it increases the clamping load (from 600 to 1400 N for a pair of steel 45/ShKh15); with increasing load, the coefficient of friction and the rate of wear decrease.

The results confirm the need to expand research into this area to solve the complex problem of increasing the reliability of tribojunctions.

Keywords: repair and restoration technologies, friction geomodifiers, serpentine, heavily loaded friction pairs

References

- Soloviov, S., Bodu, S., Trofymova, O. (2007). Porivnialnyi analiz tekhniko-ekonomichnykh i ekolohichnykh pokaznykiv khimiko-termichnoi obrobky. Tekhnohenna bezpeka. Naukovi pratsi, 61 (48), 74–78. Available at: https://lib.chmnu.edu.ua/pdf/naukpraci/technogen/2007/61-48-12.pdf

- Solov'ev, S. (2004). Upravlenie nesuschey sposobnost'yu tribosistem metodami makroprofilirovaniya rabochikh poverkhnostey. Problemy trybolohiyi, 2, 10–14.

- Solov'ev, S., Bodu, S. (2010). K naznacheniyu posadok i zazorov tsilindroporshnevykh sopryazheniy germetichnykh kompressorov. Dvigateli vnutrennego sgoraniya. Vseukrainskiy nauchno-tekhnicheskiy zhurnal, 2, 127–129. Available at: https://repository.kpi.kharkov.ua/handle/KhPI-Press/254

- Chernets, M., Klimenko, L., Pashechko, M., Nevchas, A. (2010). Tribomekhanika. Tribotekhnika. Tribotekhnologii. Vol. 3. Nikolaev: Izd-vo CHGU im. Petra Mogily.

- Soloviov, S. M., Bodu, S. Zh. (2012). Pidvyshchennia nesuchoi zdatnosti vazhkonavantazhenykh par tertia. Naukovi pratsi [Chornomorskoho derzhavnoho universytetu imeni Petra Mohyly]. Ser.: Tekhnohenna bezpeka, 203 (191), 27–31. Available at: http://nbuv.gov.ua/UJRN/Npchdutb_2012_203_191_7

- Chen, W., Gao, Y., Zhang, H. (2009). XPS and SEM Analyses of Self-Repairing Film Formed by Mineral Particles as Lubricant Additives on the Metal Friction Pairs. Advanced Tribology, 660–664. doi: https://doi.org/10.1007/978-3-642-03653-8_215

- Dolgopolov, K. N., Lyubimov, D. N., Ponomarenko, A. G., Chigarenko, G. G., Boiko, M. V. (2009). The structure of lubricating layers appearing during friction in the presence of additives of mineral friction modifiers. Journal of Friction and Wear, 30 (5), 377–380. doi: https://doi.org/10.3103/s1068366609050134

- Pogodaev, L. I., Buyanovskii, I. A., Kryukov, E. Yu., Kuz’min, V. N., Usachev, V. V. (2009). The mechanism of interaction between natural laminar hydrosilicates and friction surfaces. Journal of Machinery Manufacture and Reliability, 38 (5), 476–484. doi: https://doi.org/10.3103/s1052618809050124

- Wang, P., Lv, J., Wang, L. H., Ma, Q., Zhu, X. H. (2011). Research on Tribological Properties of Serpentine Particles as Lubricating Oil Additives. Advanced Materials Research, 284-286, 1001–1005. doi: https://doi.org/10.4028/www.scientific.net/amr.284-286.1001

- Dolgopolov, K. N., Lyubimov, D. N., Kozakov, A. T., Nikol’skii, A. V., Glazunova, E. A. (2012). Tribochemical aspects of interactions between high-dispersed serpentine particles and metal friction surface. Journal of Friction and Wear, 33 (2), 108–114. doi: https://doi.org/10.3103/s1068366612020031

- Zhang, J., Tian, B., Wang, C. (2013). Long-term surface restoration effect introduced by advanced silicate based lubricant additive. Tribology International, 57, 31–37. doi: https://doi.org/10.1016/j.triboint.2012.07.014

- Dunaev, A. V., Zuev, V., Vasilkov, D. V., Lavrov, Y., Pavlov, O. G., Pustovoy, I. F., Sokol, S. A. The hypotheses of mechanisms of action repair serpentine tribopraparatov. Trudy GOSNITI, 112 (2), 134–142. Available at: http://www.oilchoice.ru/download/file.php?id=3797

- Telukh, D., Kuz'min, V., Usachev, V. (2009). Vvedenie v problemu ispol'zovaniya sloistykh gidrosilikatov v tribosopryazheniyakh. Internet-zhurnal «Trenie, iznos, smazka», 3. Available at: http://www.oilchoice.ru/download/file.php?id=2209

- Yue, W., Wang, C., Liu, Y., Huang, H., Wen, Q., Liu, J. (2010). Study of the Regenerated Layer on the Worn Surface of a Cylinder Liner Lubricated by a Novel Silicate Additive in Lubricating Oil. Tribology Transactions, 53 (2), 288–295. doi: https://doi.org/10.1080/10402000903420787

- Qi, X., Jia, Z., Chen, H., Yang, Y., Wu, Z. (2013). Self-Repairing Characteristics of Serpentine Mineral Powder as an Additive on Steel–Chromium Plating Pair under High Temperature. Tribology Transactions, 56 (3), 516–520. doi: https://doi.org/10.1080/10402004.2013.765060

- Qi, X., Jia, Z., Yang, Y., Fan, B. (2011). Characterization and auto-restoration mechanism of nanoscale serpentine powder as lubricating oil additive under high temperature. Tribology International, 44 (7-8), 805–810. doi: https://doi.org/10.1016/j.triboint.2011.02.001

- Yuansheng, J., Shenghua, L., Zhengye, Z., He, Y., Feng, W. (2004). In situ mechanochemical reconditioning of worn ferrous surfaces. Tribology International, 37 (7), 561–567. doi: https://doi.org/10.1016/j.triboint.2003.12.005

- Nan, F., Xu, Y., Xu, B., Gao, F., Wu, Y., Li, Z. (2015). Tribological behaviors and wear mechanisms of ultrafine magnesium aluminum silicate powders as lubricant additive. Tribology International, 81, 199–208. doi: https://doi.org/10.1016/j.triboint.2014.09.006

- Zhang, B., Xu, B., Xu, Y., Zhang, B. (2011). Tribological characteristics and self-repairing effect of hydroxy-magnesium silicate on various surface roughness friction pairs. Journal of Central South University, 18 (5), 1326–1333. doi: https://doi.org/10.1007/s11771-011-0841-0

- Yu, H., Xu, Y., Shi, P., Wang, H., Wei, M., Zhao, K., Xu, B. (2013). Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear, 297 (1-2), 802–810. doi: https://doi.org/10.1016/j.wear.2012.10.013

- Yu, H. L., Xu, Y., Shi, P. J., Wang, H. M., Zhang, W., Xu, B. S. (2011). Effect of thermal activation on the tribological behaviours of serpentine ultrafine powders as an additive in liquid paraffin. Tribology International, 44 (12), 1736–1741. doi: https://doi.org/10.1016/j.triboint.2011.06.022

- Kadoshnikov, V. M., Shekhunova, S. B., Zadvernyuk, H. P., Manichev, V. I. (2013). Authigenic minerals in the bentonite clay of Cherkassy deposit. Mineralogical Journal, 35 (3), 54–60. Available at: http://www.irbis-nbuv.gov.ua/cgi-bin/irbis_nbuv/cgiirbis_64.exe?C21COM=2&I21DBN=UJRN&P21DBN=UJRN&Z21ID=&IMAGE_FILE_DOWNLOAD=1&Image_file_name=PDF/Mineral_2013_35_3_8.pdf

- De Barros Bouchet, M. I., Kano, M. (2007). Superlubricity of Diamond/Glycerol Technology Applied to Automotive Gasoline Engines. Superlubricity, 471–492. doi: https://doi.org/10.1016/b978-044452772-1/50056-1

- Erdemir, A., Eryilmaz, O. L. (2007). Superlubricity in Diamondlike Carbon Films. Superlubricity, 253–271. doi: https://doi.org/10.1016/b978-044452772-1/50047-0

- Fontaine, J., Donnet, C. (2007). Superlow Friction of a-C:H Films: Tribochemical and Rheological Effects. Superlubricity, 273–294. doi: https://doi.org/10.1016/b978-044452772-1/50048-2

- Yuansheng, J., Shenghua, L. (2007). Superlubricity of In Situ Generated Protective Layer on Worn Metal Surfaces in Presence of Mg6Si4O10(OH)8. Superlubricity, 445–469. doi: https://doi.org/10.1016/b978-044452772-1/50055-x

- Freyman, C., Zhao, B., Chung, Y.-W. (2007). Suppression of Moisture Sensitivity of Friction in Carbon-Based Coatings. Superlubricity, 295–310. doi: https://doi.org/10.1016/b978-044452772-1/50049-4

- Kano, M. (2015). Overview of DLC-Coated Engine Components. Coating Technology for Vehicle Applications, 37–62. doi: https://doi.org/10.1007/978-3-319-14771-0_3

- Donnet, C., Erdemir, A. (Eds.) (2008). Tribology of Diamond-Like Carbon Films. Springer. doi: https://doi.org/10.1007/978-0-387-49891-1

- Nagashima, S., Moon, M.-W. (2015). Diamond-Like Carbon Coatings with Special Wettability for Automotive Applications. Coating Technology for Vehicle Applications, 191–202. doi: https://doi.org/10.1007/978-3-319-14771-0_11

- Street, K. W., Miyoshi, K., Vander Wal, R. L. (2007). Application of Carbon Based Nano-Materials to Aeronautics and Space Lubrication. Superlubricity, 311–340. doi: https://doi.org/10.1016/b978-044452772-1/50050-0

- Nakayama, K. (1995). Triboemission And Wear Of Hydrogenated Carbon Films. MRS Proceedings, 409. doi: https://doi.org/10.1557/proc-409-391

- Balabanov, V. I., Boykov, V. Yu., Balabanova, T. V. (2016). Analyzing repair and reconstructive composites for automotive and tractor mashinery. Agroinzheneriya, 3, 45–52. Available at: https://cyberleninka.ru/article/n/issledovanie-remontno-vosstanovitelnyh-sostavov-dlya-avtotraktornoy-tehniki

- Olishevska, V., Bas, K., Litvin, P. (2010). Treatment of machines friction connections by nanotribosubstances ат dismantling service. Visnyk Kharkivskoho natsionalnoho avtomobilno-dorozhnoho universytetu, 51, 156–161. Available at: https://cyberleninka.ru/article/n/obrabotka-truschihsya-soedineniy-mashin-nanotribopreparatami-pri-bezrazbornom-servise

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Svіtlana Bodu, Vyacheslav Andrieiev, Anton Novoshytskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.