Determining the effect of anti-friction additive on the power of mechanical losses in a rotary piston engine

DOI:

https://doi.org/10.15587/1729-4061.2023.284500Keywords:

rotary piston engine, mechanical losses, anti-friction additive, pumping strokeAbstract

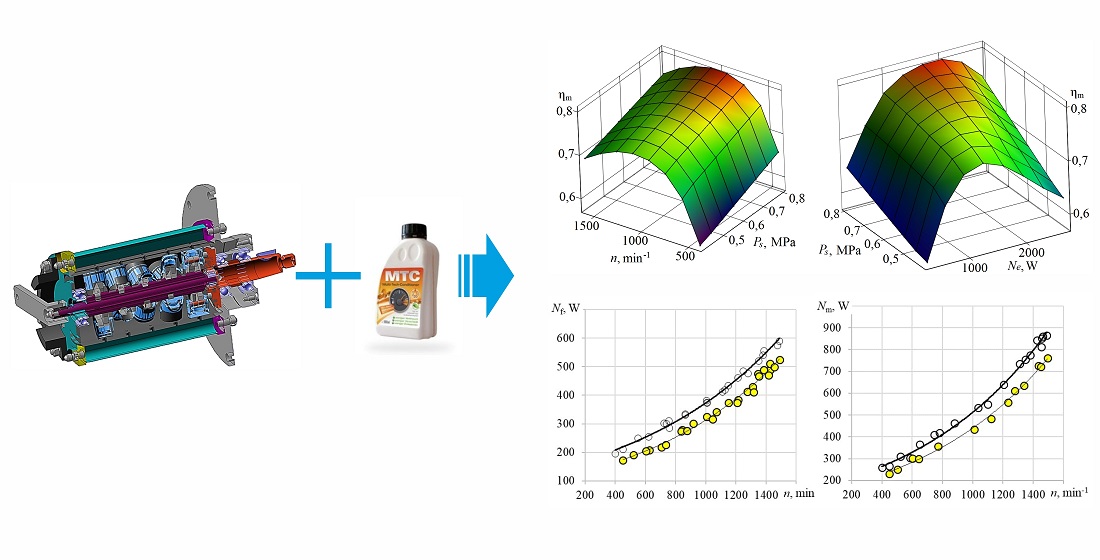

Experimental studies of the effect of adding the antifriction additive Multi-Tech-Conditioner to lubricating oil on the power of mechanical losses of a rotary piston engine were carried out, the purpose of which was to reduce the cost of potential energy of a compressed working fluid to overcome friction forces. The experimental data obtained make it possible to estimate the value of irretrievable losses of the available power of a rotary piston engine at the stage of its design and operation.

Experimentally, a positive effect of the addition of the Multi-Tech-Conditioner antifriction additive to lubricating oil on the change in the power of mechanical losses of the engine was established, which was reflected in a decrease in total losses over the entire operational range of change in the rotor speed by 11.8 %. As a result of the research, it was determined that the losses for pumping strokes (gas exchange) in a rotary piston engine amount to 31.6 % of the total power of mechanical losses.

An assessment was made of change in the mechanical efficiency of a rotary piston engine with a hinged-cam mechanism for converting motion under the conditions of applying an antifriction additive to lubricating oil. It has been established that the addition of the Multi-Tech-Conditioner additive to the lubricating oil in a ratio of 1:14 makes it possible to increase the mechanical efficiency of a rotary piston engine depending on the speed by 3.8–5.5 % for all operating pressures in the inlet receiver.

Based on the generalization and systematization of the obtained experimental data on the use of the Multi-Tech-Conditioner additive, the most rational operating ranges of a new design rotary piston engine were identified. The maximum mechanical efficiency of a rotary piston engine is achieved in the load range of 65...75 % of the rated power, and the speed range is 63...70 %

References

- Mytrofanov, O., Proskurin, A., Poznanskyi, A. (2021). Research of rotary piston engine use in transport power plants. Transport Problems, 16 (1), 165–178. doi: https://doi.org/10.21307/tp-2021-014

- Parsadanov, I. V., Belik, S. Yu. (2008). Mnogofaktornyy analiz mekhanicheskikh poter' v bystrokhodnom dizele s gazoturbinnym nadduvom. Dvigateli vnutrennego sgoraniya, 1, 34–37. Available at: https://repository.kpi.kharkov.ua/items/a4794f4f-f1ca-41ce-a49a-38f49b524b0b

- Zeng-hong, S., Yu-cai, Y., Dan, Q. (2019). Research progress of Lubricant additives. LUBRICARING OIL, 34(05), 16-22.

- Herdan, J. M. (1997). Lubricating oil additives and the environment – an overview. Lubrication Science, 9 (2), 161–172. doi: https://doi.org/10.1002/ls.3010090205

- Syahir, A. Z., Masjuki, H. H., Yusoff, M. N. A. M., Ibrahim, T. M. (2022). Frictional Power Evaluation of Additive-Mixture in Trimethylolpropane Trioleate Oil using Single Cylinder Diesel Engine. IOP Conference Series: Materials Science and Engineering, 1244 (1), 012011. doi: https://doi.org/10.1088/1757-899x/1244/1/012011

- Fan, B., Li, Z., Sun, A., Guo, Y., Qi, X., Liu, C. (2022). Experimental Study on Tribological Properties of Polymer-based Composite Nano-additives Suitable for Armored Vehicle Engine Lubricating Oil. MATEC Web of Conferences, 358, 01009. doi: https://doi.org/10.1051/matecconf/202235801009

- Öğüt, H., Oğuz, H., Aydın, F., Ciniviz, M., Deveci, H. (2019). The effects of the use of vegetable oil based as engine lubrication oil on engine performance and emissions in diesel engines. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 42 (19), 2381–2396. doi: https://doi.org/10.1080/15567036.2019.1668507

- Alqahtani, B., Hoziefa, W., Abdel Moneam, H. M., Hamoud, M., Salunkhe, S., Elshalakany, A. B. et al. (2022). Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants, 10 (7), 137. doi: https://doi.org/10.3390/lubricants10070137

- Varbanets, R. A., Ivanovskiy, V. G., Yakimenko, N. G. (2009). Rezul'taty ispytaniy raboty dizelya 4CH17.5/24 s prisadkoy k maslu “Multi-Tech Conditioner”. Suchasni problemy dvyhunobuduvannia: stan, idei, rishennia: III Vseukrainskaya nauchno-tekhnicheskaya konferentsiya. Pervomaysk, 108–113.

- Varbanets, R. A., Ivanovskiy V. G., Aleksandrovskaya, N. I., Kucherenko, Yu. N. (2014). Ispytaniya raboty dizelya 4CH17.5/24 s prisadkoy k maslu «multi-tech conditioner». Problemy khimmotolohiyi. Teoriya ta praktyka ratsionalnoho vykorystannia tradytsiynykh i alternatyvnykh palyvno-mastylnykh materialiv. Materialy V Mizhnarodnoi naukovo-tekhnichnoi konferentsiyi. Kyiv, 190–194.

- Mytrofanov, O., Proskurin, A., Poznanskyi, A., Zivenko, O. (2022). Determining the power of mechanical losses in a rotary-piston engine. Eastern-European Journal of Enterprise Technologies, 3 (8 (117)), 32–38. doi: https://doi.org/10.15587/1729-4061.2022.256115

- Testergebnisse. Available at: https://www.mtc-oil.com/referenzen-tests/

- Mytrofanov, O. S., Shabalin, Yu. V., Biriuk, T. F., Yefenina, L. O. (2019). Pat. No. 120489 UA. Porshneva mashyna. No. a201902189; declareted: 10.09.2019; published: 10.12.2019. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=263906

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleksandr Mytrofanov, Arkadii Proskurin, Andrii Poznanskyi, Oleksii Zivenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.