Development of an A1100 aluminum corrugated metal gaskets

DOI:

https://doi.org/10.15587/1729-4061.2023.284502Keywords:

gasket development, finite element analysis, corrugated metal gasket, cold forming, aluminum materials, water pressure testAbstract

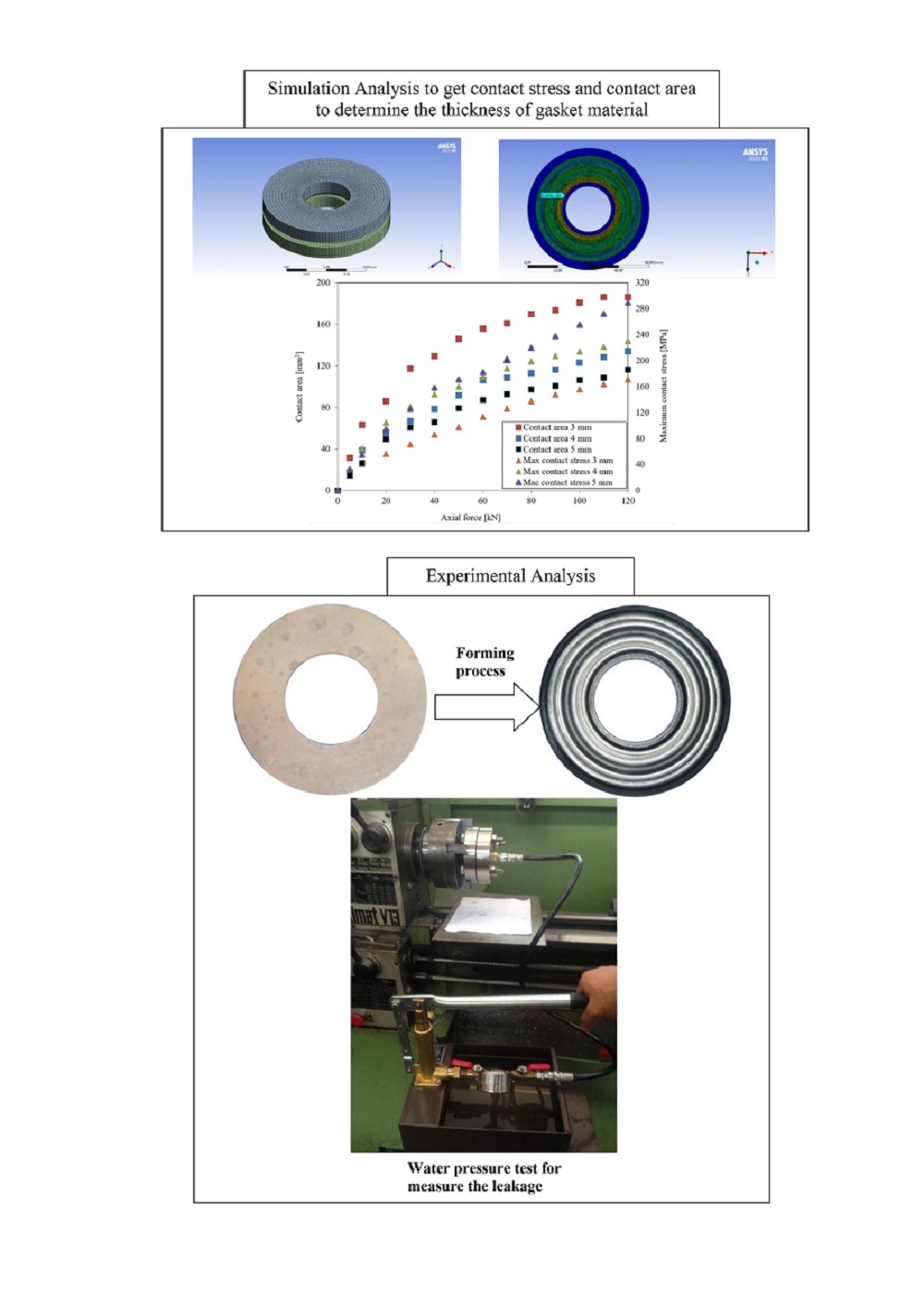

Corrugated metal gaskets (CMG) made from SUS304 have previously been developed, however a coating process with a softer material is necessary for its design to be optimal. The coating process is time consuming and expensive. This research aims to develop CMG from aluminum by simulation analysis and form a CMG design made of aluminum A1100. The method used is development research. The optimum CMG thickness is analyzed using ANSYS Finite Element Analysis (FEA). The control variables being investigated are contact area and contact stress. The independent variable being investigated is the material thickness of CMG. An aluminum gasket is then constructed using a cold-forming process based on the optimum design. The control variables in the leak test are axial force and water pressure. Experiments were also carried out to test the aluminum gasket for leakage. A leakage test is carried out using a water pressure test. Simulation analysis showed results that were in line with experimental leak tests. FEA simulation results show that the optimum gasket thickness is between 3 and 5 mm, with 5 mm being the most optimal. However, CMG with thicknesses of 4 and 5 have similar contact stress and contact area. Leakage test results also show similarities with simulation results. CMG with a thickness of 5 mm has the best performance. The experimental results show that CMG made from aluminum A1100 is suitable for use as a gasket to prevent leakage, it prevents leakage at fluid pressure up to 12 MPa and axial force 100 kN. The results show that aluminum CMG performs on par with SUS304 CMG coated with nickel or copper. This research succeeded in developing CMG made of aluminum

References

- Saeed, H. A., Izumi, S., Sakai, S., Haruyama, S., Nagawa, M., Noda, H. (2008). Development of New Metallic Gasket and its Optimum Design for Leakage Performance. Journal of Solid Mechanics and Materials Engineering, 2 (1), 105–114. doi: https://doi.org/10.1299/jmmp.2.105

- Karohika, I. M. G., Antara, I. N. G. (2019). The metal gasket sealing performance of bolted flanged with fem analysis. IOP Conference Series: Materials Science and Engineering, 539 (1), 012018. doi: https://doi.org/10.1088/1757-899x/539/1/012018

- Choiron, M. A., Haruyama, S., Kaminishi, K. (2011). Optimization of New Metal Gasket Design Based on Contact Width Involving Contact Stress Consideration. Applied Mechanics and Materials, 110-116, 4780–4787. doi: https://doi.org/10.4028/www.scientific.net/amm.110-116.4780

- Haruyama, S., Nurhadiyanto, D., Choiron, M. A., Kaminishi, K. (2013). Influence of surface roughness on leakage of new metal gasket. International Journal of Pressure Vessels and Piping, 111-112, 146–154. doi: https://doi.org/10.1016/j.ijpvp.2013.06.004

- Haruyama, S., Nurhadiyanto, D., Kaminishi, K. (2013). Contact Width Analysis of Corrugated Metal Gasket Based on Surface Roughness. Advanced Materials Research, 856, 92–97. doi: https://doi.org/10.4028/www.scientific.net/amr.856.92

- Haruyama, S., Choiron, Moch. A., Nurhadiyanto, D. (2019). Optimum Design of Laminated Corrugated Metal Gasket Using Computer Simulation. International Journal of Integrated Engineering, 11 (5). doi: https://doi.org/10.30880/ijie.2019.11.05.004

- Choiron, Moch. A., Purnowidodo, A. (2015). Sealing Performance of Thin Corrugated Metal Gasket. Applied Mechanics and Materials, 789-790, 246–250. doi: https://doi.org/10.4028/www.scientific.net/amm.789-790.246

- Nurhadiyanto, D., Mujiyono, Sutopo, Amri Ristadi, F. (2018). Simulation Analysis of 25A-Size Corrugated Metal Gasket Coated Copper to Increase Its Performance. IOP Conference Series: Materials Science and Engineering, 307, 012005. doi: https://doi.org/10.1088/1757-899x/307/1/012005

- Nurhadiyanto, D., Haruyama, S., Mujiyono, Sutopo, Ristadi, F. A. (2020). The performance of nickel and copper as coating materials for corrugated metal gaskets. Journal of Engineering Science and Technology, 15 (4), 2450–2463. Available at: https://jestec.taylors.edu.my/Vol%2015%20issue%204%20August%202020/15_4_23.pdf

- Nurhadiyanto, D., Haruyama, S., Mujiyono, M., Sutopo, S., Yunaidi, Y., Surahmanto, F. et al. (2021). Improved performance of corrugated metal gaskets in boiler’s piping system through multilayered coating. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 13–20. doi: https://doi.org/10.15587/1729-4061.2021.245360

- Karohika, I. M. G., Antara, I. N. G., Budiana, I. M. D. (2019). Influence of dies type for gasket forming shape. IOP Conference Series: Materials Science and Engineering, 539 (1), 012019. doi: https://doi.org/10.1088/1757-899x/539/1/012019

- Gothivarekar, S., Coppieters, S., Van de Velde, A., Debruyne, D. (2020). Advanced FE model validation of cold-forming process using DIC: Air bending of high strength steel. International Journal of Material Forming, 13 (3), 409–421. doi: https://doi.org/10.1007/s12289-020-01536-1

- He, L., Lu, X., Zhu, X., Chen, Q. (2021). Influence of Structural Parameters of Shape Memory Alloy Corrugated Gaskets on the Contact Pressure of Bolted Flange Joints. Advances in Materials Science and Engineering, 2021, 1–19. doi: https://doi.org/10.1155/2021/5552569

- Jianjun, S., Chenbo, M., Jianhua, L., Qiuping, Y. (2018). A leakage channel model for sealing interface of mechanical face seals based on percolation theory. Tribology International, 118, 108–119. doi: https://doi.org/10.1016/j.triboint.2017.09.013

- Liu, Y., Du, H., Ren, X., Li, B., Qian, J., Yan, F. (2022). A Leakage Rate Model for Metal-to-Metal Seals Based on the Fractal Theory of Porous Medium. Aerospace, 9 (12), 779. doi: https://doi.org/10.3390/aerospace9120779

- Du, P., Lu, J., Tuo, J., Wang, X. (2019). Research on the Optimization Design of Metallic Gasket Based on DOE Methodology. IOP Conference Series: Materials Science and Engineering, 569 (3), 032027. doi: https://doi.org/10.1088/1757-899x/569/3/032027

- Zhan, Y., Lan, M., Zhu, X., Lu, X. (2022). Research on Prediction Models for the Compression-Resilience Performance of Corrugated Metal Gaskets With Residual Stress. Journal of Pressure Vessel Technology, 144 (5). doi: https://doi.org/10.1115/1.4053602

- JIS Z 2241. Metallic Material-Tensile testing-Method of test at room temperature. Japanese Standards Association. Available at: https://global.ihs.com/doc_detail.cfm?&item_s_key=00127867&item_key_date=770310&input_doc_number=JISZ2241&input_doc_title

- Materials Data Book (2019). Cambridge University Engineering Department. Available at: http://teaching.eng.cam.ac.uk/sites/teaching.eng.cam.ac.uk/files/Documents/Databooks/MATERIALS%20DATABOOK%20(2011)%20version%20for%20Moodle.pdf

- Karohika, I. M. G., Artha, I. G. A. G. K., Azkandri, M. H. A. G. (2023). An overview of the corrugated metal gasket. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0115569

- Karohika, I. M. G., Antara, I. N. G. (2019). Gasket Process Parameter in Metal Forming. IOP Conference Series: Earth and Environmental Science, 248, 012044. doi: https://doi.org/10.1088/1755-1315/248/1/012044

- JIS B 2404:2006. Dimensions of gaskets for use with pipe flanges. Japanese Standards Association. Available at: https://infostore.saiglobal.com/en-us/standards/jis-b-2404-2006-622826_saig_jsa_jsa_2891706/

- JIS B 2220:2004. Steel Pipe Flanges. Japanese Standards Association. Available at: https://infostore.saiglobal.com/en-us/standards/jis-b-2220-2004-633314_saig_jsa_jsa_1452418/

- Tatarkanov, A., Aleksandrov, I., Mihaylov, M., Muranov, A. (2021). Development of algorithm for automated assessment of the tightness of contact sealing connections of isolation valves. Bulletin of Bryansk State Technical University, 10, 27–37. doi: https://doi.org/10.30987/1999-8775-2021-10-27-37

- Bhosale, R. S., Kumbhar, P. P., Mahajan, K. S., Yachkal, A. K., Katarkar, A., (2017). Study on Leak Testing Methods. International Journal for Scientific Research & Development, 5 (1), 1618–1621. Available at: https://www.researchgate.net/publication/323219717_Study_on_Leak_Testing_Methods#fullTextFileContent

- Feng, X., Gu, B., Zhang, P. (2018). Prediction of Leakage Rates Through Sealing Connections with Metallic Gaskets. IOP Conference Series: Earth and Environmental Science, 199, 032090. doi: https://doi.org/10.1088/1755-1315/199/3/032090

- Karohika, I. M. G., Haruyama, S., Choiron, Moch. A., Nurhadiyanto, D., Antara, I. N. G. et al. (2020). An Approach to Optimize the Corrugated Metal Gasket Design Using Taguchi Method. International Journal on Advanced Science, Engineering and Information Technology, 10 (6), 2435. doi: https://doi.org/10.18517/ijaseit.10.6.12992

- Karohika, I. M. G., Haruyama, S. (2022). Analysis of three-layer gasket performance affected by flange surface. EUREKA: Physics and Engineering, 4, 57–66. doi: https://doi.org/10.21303/2461-4262.2022.002290

- Karohika, I. M. G., Haruyama, S. (2022). The real contact width evaluation of a three-layer metal gasket. SINERGI, 26 (3), 311. doi: https://doi.org/10.22441/sinergi.2022.3.006

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Didik Nurhadiyanto, Mujiyono, Febrianto Amri Ristadi, Ardani Ahsanul Fakhri, Gewa Ardeva, Muhammad Iqbal Kusnantoro, Shigeyuki Haruyama, Isti Yunita, Alexander Panichkin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.