Establishment of patterns in the thermal modification of dry pine wood

DOI:

https://doi.org/10.15587/1729-4061.2023.285509Keywords:

dry pine wood, thermal modification, change in wood structure, strength limitAbstract

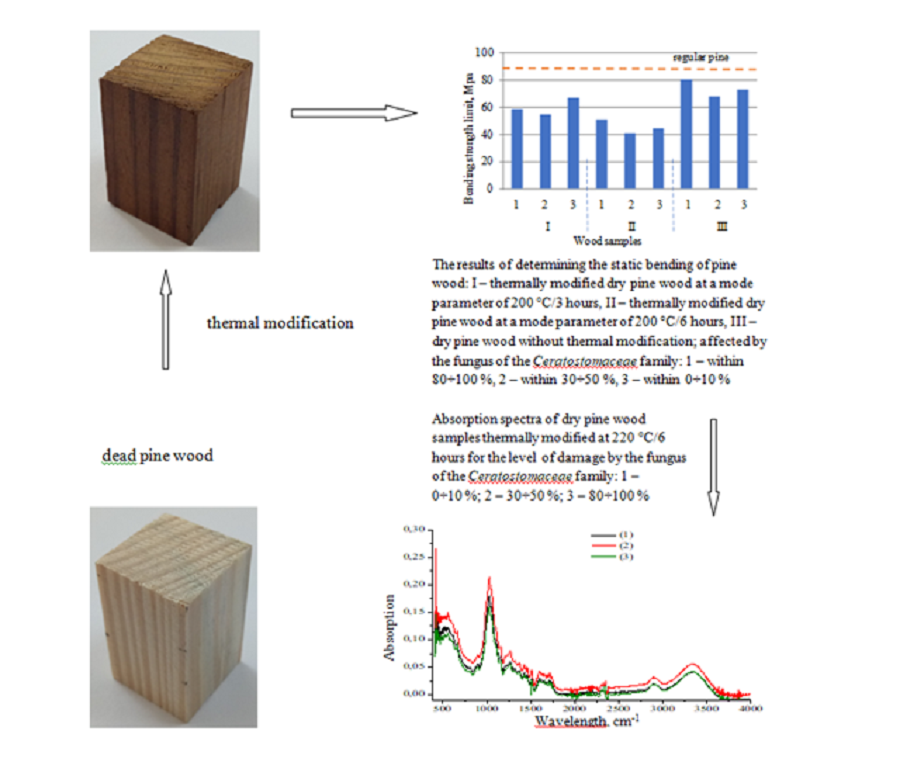

One of the methods of ensuring the durability of dry wood during operation is its thermal modification, which inhibits the life processes of the fungus of the Ceratostomaceae family and leads to a change in its structure and properties. Therefore, the object of research was thermally modified dry pine wood affected by a fungus of the Ceratostomaceae family. Physicochemical studies of changes in the structure of thermally modified dry pine wood showed that the samples have absorption spectra that are characterized by fluctuations of the glucopyranose ring of cellulose and are an indicator of the beginning of destructive processes. At the same time, the data of thermogravimetric analysis show the processes of water loss and decomposition of hemicellulose, cellulose, and lignin, and burning of coke residue. Bending and compressive strength of thermally modified dry pine wood shows that as the wood dries, the strength limit decreases depending on the degree of fungus damage. Namely, with an area of biological damage within 10 %, the strength limit is reduced by more than 1.2 times when modified at 200 °С/3 hours, by more than 1.9 times at 200 °С/6 hours. With an increase in the degree of fungal damage to 30÷50 %, the strength limit decreases by more than 1.6 times when modified at 200 °С/3 hours, by more than 2.1 at 200 °С/6 hours. And when affected by a fungus in the range of 80÷100 %, the wood becomes softer, more plastic, while the bending strength is reduced by 1.7 times, and the compressive strength by 1.16 times. Thermal modification of dry pine wood at 200 °С for 3 hours reduces the level of water absorption by more than 1.5 times, and for 6 hours ‒ by more than 1.7 times. The practical importance is that the results of determining changes in the structure and properties of thermally modified dry pine wood make it possible to establish the scope and conditions of its application

References

- Brischke, C., Alfredsen, G. (2020). Wood-water relationships and their role for wood susceptibility to fungal decay. Applied Microbiology and Biotechnology, 104 (9), 3781–3795. doi: https://doi.org/10.1007/s00253-020-10479-1

- Amirou, S., Pizzi, A., Delmotte, L. (2019). Investigations of mechanical properties and chemical changes occurring during welding of thermally modified ash wood. Journal of Adhesion Science and Technology, 34 (1), 13–24. doi: https://doi.org/10.1080/01694243.2019.1659569

- Lo Monaco, A., Luziatelli, G., Latterini, F., Tavankar, F., Picchio, R. (2020). Structure and Dynamics of Deadwood in Pine and Oak Stands and their Role in CO2 Sequestration in Lowland Forests of Central Italy. Forests, 11 (3), 253. doi: https://doi.org/10.3390/f11030253

- Maillard, F., Jusino, M. A., Andrews, E., Moran, M., Vaziri, G. J., Banik, M. T. et al. (2022). Wood-decay type and fungal guild dominance across a North American log transplant experiment. Fungal Ecology, 59, 101151. doi: https://doi.org/10.1016/j.funeco.2022.101151

- Fukasawa, Y., Kaga, K. (2022). Surface Area of Wood Influences the Effects of Fungal Interspecific Interaction on Wood Decomposition – A Case Study Based on Pinus densiflora and Selected White Rot Fungi. Journal of Fungi, 8 (5), 517. doi: https://doi.org/10.3390/jof8050517

- Kim, S., Han, S. H., Li, G., Roh, Y., Kim, H.-J., Son, Y. (2021). The initial effects of microclimate and invertebrate exclusion on multi-site variation in the mass loss of temperate pine and oak deadwoods. Scientific Reports, 11 (1). doi: https://doi.org/10.1038/s41598-021-94424-w

- Pastorelli, R., Paletto, A., Agnelli, A. E., Lagomarsino, A., De Meo, I. (2021). Microbial Diversity and Ecosystem Functioning in Deadwood of Black Pine of a Temperate Forest. Forests, 12 (10), 1418. doi: https://doi.org/10.3390/f12101418

- Lee, M. R., Oberle, B., Olivas, W., Young, D. F., Zanne, A. E. (2020). Wood construction more strongly shapes deadwood microbial communities than spatial location over 5 years of decay. Environmental Microbiology, 22 (11), 4702–4717. doi: https://doi.org/10.1111/1462-2920.15212

- Härtl, F. H., Langhammer, P., Knoke, T. (2018). Strategies aimed to minimize opportunity costs regarding the provision of deadwood. Schweizerische Zeitschrift Fur Forstwesen, 169 (1), 9–17. doi: https://doi.org/10.3188/szf.2018.0009

- Altgen, M., Kyyrö, S., Paajanen, O., Rautkari, L. (2019). Resistance of thermally modified and pressurized hot water extracted Scots pine sapwood against decay by the brown-rot fungus Rhodonia placenta. European Journal of Wood and Wood Products, 78 (1), 161–171. doi: https://doi.org/10.1007/s00107-019-01482-z

- Bojanowska, M., Chmiel, J., Sozańska, M., Chmiela, B., Grudzień, J., Halska, J. (2021). Issues of Corrosion and Degradation under Dusty Deposits of Energy Biomass. Energies, 14 (3), 534. doi: https://doi.org/10.3390/en14030534

- Clausen, C. A. (1996). Bacterial associations with decaying wood: a review. International Biodeterioration & Biodegradation, 37 (1-2), 101–107. doi: https://doi.org/10.1016/0964-8305(95)00109-3

- Embacher, J., Zeilinger, S., Kirchmair, M., Rodriguez-R, L. M., Neuhauser, S. (2023). Wood decay fungi and their bacterial interaction partners in the built environment – A systematic review on fungal bacteria interactions in dead wood and timber. Fungal Biology Reviews, 45, 100305. doi: https://doi.org/10.1016/j.fbr.2022.100305

- Poonia, P. K., Deepa, S. R., Kumar, M., Kumar, A. (2020). Viability of wood decaying fungal mycelium after microwave radiation of bamboo culm. Maderas. Ciencia y Tecnología, 23. doi: https://doi.org/10.4067/s0718-221x2021000100404

- Tsapko, Y., Likhnyovskyi, R., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K. et al. (2022). Identifying parameters for wood protection against water absorption. Eastern-European Journal of Enterprise Technologies, 6 (10 (120)), 71–81. doi: https://doi.org/10.15587/1729-4061.2022.268286

- ISO 13061-3:2014. Physical and mechanical properties of wood – Test methods for small clear wood specimens – Part 3: Determination of ultimate strength in static bending. Available at: https://www.iso.org/standard/60065.html

- Pettersen, R. C. (1984). The Chemical Composition of Wood. The Chemistry of Solid Wood, 57–126. doi: https://doi.org/10.1021/ba-1984-0207.ch002

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of Polymer Science Part A-2: Polymer Physics, 7 (10), 1761–1773. doi: https://doi.org/10.1002/pol.1969.160071012

- Emmanuel, V., Odile, B., Céline, R. (2015). FTIR spectroscopy of woods: A new approach to study the weathering of the carving face of a sculpture. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 136, 1255–1259. doi: https://doi.org/10.1016/j.saa.2014.10.011

- Shi, J., Xing, D., Lia, J. (2012). FTIR Studies of the Changes in Wood Chemistry from Wood Forming Tissue under Inclined Treatment. Energy Procedia, 16, 758–762. doi: https://doi.org/10.1016/j.egypro.2012.01.122

- Tsapko, Y., Buiskykh, N., Likhnyovskyi, R., Horbachova, O., Tsapko, А., Mazurchuk, S. et al. (2022). Establishing regularities in the application of dry pine wood. Eastern-European Journal of Enterprise Technologies, 4 (10 (118)), 51–59. doi: https://doi.org/10.15587/1729-4061.2022.262203

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K., Matviichuk, A. (2022). Establishing regularities of wood protection against water absorption using a polymer shell. Eastern-European Journal of Enterprise Technologies, 1 (10 (115)), 48–54. doi: https://doi.org/10.15587/1729-4061.2022.252176

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K., Matviichuk, A. (2021). Determining patterns in reducing the level of bio-destruction of thermally modified timber after applying protective coatings. Eastern-European Journal of Enterprise Technologies, 5 (10 (113)), 48–55. doi: https://doi.org/10.15587/1729-4061.2021.242899

- Tsapko, Y., Horbachova, O., Tsapko, А., Mazurchuk, S., Zavialov, D., Buiskykh, N. (2021). Establishing regularities in the propagation of phase transformation front during timber thermal modification. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 30–36. doi: https://doi.org/10.15587/1729-4061.2021.225310

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Bondarenko, O. (2021). Study of resistance of thermomodified wood to the influence of natural conditions. IOP Conference Series: Materials Science and Engineering, 1164 (1), 012080. doi: https://doi.org/10.1088/1757-899x/1164/1/012080

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Bondarenko, O. P. (2022). Specific Aspects of the Study of the Surface Properties of Plywood. Materials Science Forum, 1066, 175–182. doi: https://doi.org/10.4028/p-b15jpx

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Bondarenko, O. (2023). Study of surface properties on cellulose-containing material for creating a protective coating. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0124505

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuriy Tsapko, Oleksandra Horbachova, Ruslan Likhnyovskyi, Serhii Mazurchuk, Аleksii Tsapko, Nataliia Buiskykh, Andrii Matviichuk, Oksana Slutska, Olena Korolova, Dmytro Khromenkov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.