Revealing patterns in the stressed-strained state of load-bearing structures in special rolling stock to further improve them

DOI:

https://doi.org/10.15587/1729-4061.2023.285894Keywords:

car, dump car, girder beam, dump car strength, calculated loadsAbstract

The object of research is strength indicators of load-bearing structures of special rolling stock (dump cars). The research problem is the appearance of the same type of cracks in the girder beams of dump cars, the repair of which is not provided for by the current repair documentation. Malfunction analysis, control tests, strength studies by calculation and experiment were carried out.

The analysis of malfunctions of cars in operation helped prove the place of occurrence of fatigue defects – the girder beam. This made it possible to determine specific zones of load-bearing elements, in which during control tests of cars, on the basis of taking into account data on fatigue defects, it is necessary to measure stress parameters.

The results of the control tests showed that the lowest value of the fatigue resistance reserve factor n=1.6 for the dump car is found in the zone on the girder beam in the area of the pivot beam. The value of n is within acceptable limits.

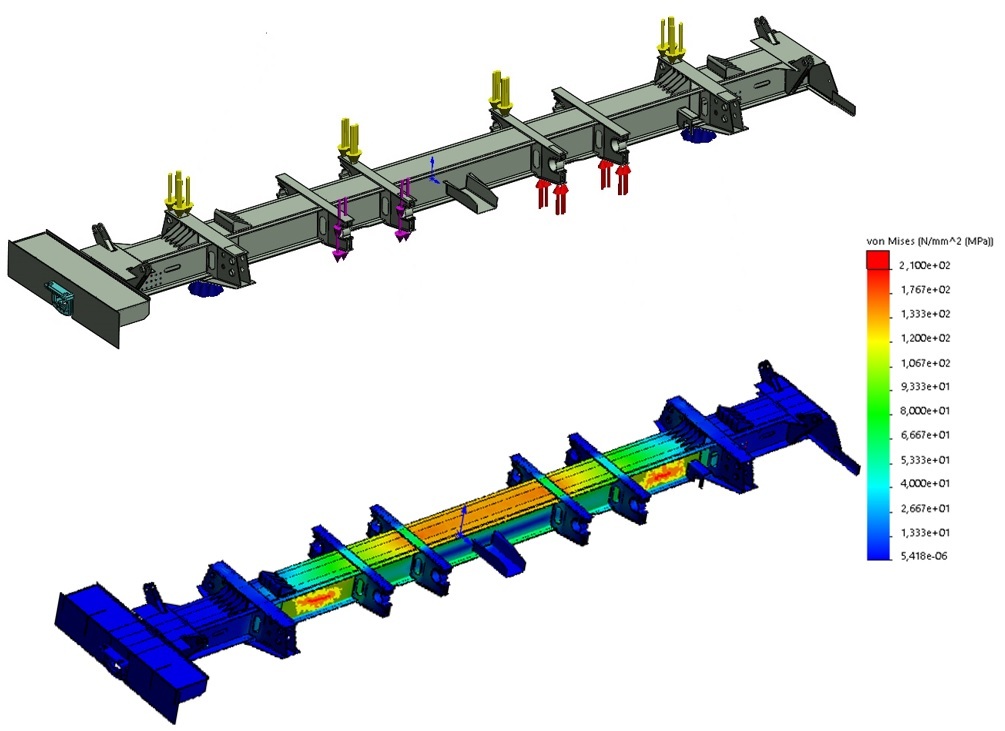

Normative calculations were carried out and a separate calculation (emergency) mode was additionally defined in the SolidWorks Simulation 2019 software package (France). Based on the results of the dump car stress calculations, it was established that the maximum equivalent stresses in the load-bearing structures of the car occur during its unloading due to twisting, and the stress vectors are at an angle of 45°. During the calculation of individual load modes, the stresses exceed the permissible values.

In order to ensure the necessary strength conditions, it is proposed to introduce a reinforcing pad into the girder beam of the dump car, due to which the calculated stresses are within the permissible limits.

The research will contribute to devising the recommendations for the restoration of dump cars, for designing modern structures of special rolling stock, and for improving strength determination processes

References

- Cole, C., Spiryagin, M., Wu, Q., Sun, Y. Q. (2017). Modelling, simulation and applications of longitudinal train dynamics. Vehicle System Dynamics, 55 (10), 1498–1571. doi: https://doi.org/10.1080/00423114.2017.1330484

- Hecht, M. (2014). Innovative rail freight wagons – a precondition to increase the market-share of rail freight. Archives of Transport, 29 (1), 17–26. doi: https://doi.org/10.5604/08669546.1146959

- Horobets, V. L., Miamlin, S. V., Yanhulova, O. L. (2015). Perspektyvy rozvytku metodiv otsinky sroku sluzhby rukhomoho skladu zaliznyts. Visnyk sertyfikatsii zaliznychnoho transportu, 8, 44–47.

- Leonets, V. A. (2017). Vplyv tryvaloi ekspluatatsiyi zaliznychnoho rukhomoho skladu na pratsezdatnist yoho nesuchykh konstruktsiy. Zaliznychnyi transport Ukrainy, 1, 24–31. Available at: http://nbuv.gov.ua/UJRN/ZTU_2017_1_6

- Li, X., Fang, J., Zhang, Q., Zhao, S., Guan, X. (2020). Study on Key Technology of Railway Freight Car Body Fatigue Test. Journal of Failure Analysis and Prevention, 20 (1), 261–269. doi: https://doi.org/10.1007/s11668-020-00828-7

- Barbas, I. H., Kostritsa, S. O., Datsenko, V. N., Sultan, A. V., Dzychkovskyi, Ye. M., Krivchykov, A. Ye. (2009). The study of dynamics and strength of hoppers (review article). Science and Transport Progress, 30, 27–32. doi: https://doi.org/10.15802/stp2009/14600

- Sulym, A., Khozia, P., Strynzha, A., Rechkalov, V., Fedorov, V. (2022). Approaches and prospects of improvement of dump cars for operation on 1520-mm mainline railways. Collection of Scientific Works of the State University of Infrastructure and Technologies Series “Transport Systems and Technologies,” 39, 51–65. doi: https://doi.org/10.32703/2617-9040-2022-39-6

- Zhang, Q., Li, X., Ma, Y., Li, W. (2023). Fatigue test loading method for wagon body based on measured load. Railway Sciences, 2 (1), 68–83. doi: https://doi.org/10.1108/rs-01-2023-0001

- Gawlak, K. (2022). Safety critical components (SCC) in the maintenance management system for railway vehicle. Diagnostyka, 23 (4), 1–9. doi: https://doi.org/10.29354/diag/156166

- Pɫaczek, M., Wróbel, A., Buchacz, A. (2016). A concept of technology for freight wagons modernization. IOP Conference Series: Materials Science and Engineering, 161, 012107. doi: https://doi.org/10.1088/1757-899x/161/1/012107

- Assemkhanuly, A., Niyazova, Z., Ustemirova, R., Karpov, A., Muratov, A., Kaspakbayev, K. (2019). Mathematical and computer models in estimation of dynamic processes of vehicles. Journal of Theoretical and Applied Information Technology, 97 (10), 2803–2820. Available at: http://www.jatit.org/volumes/Vol97No10/14Vol97No10.pdf

- Poveda-Reyes, S., Rizzetto, L., Triti, C., Shi, D., García-Jiménez, E., Molero, G. D., Santarremigia, F. E. (2021). Risk evaluation of failures of the running gear with effects on rail infrastructure. Engineering Failure Analysis, 128, 105613. doi: https://doi.org/10.1016/j.engfailanal.2021.105613

- Jagadish, H. V. (2015). Big Data and Science: Myths and Reality. Big Data Research, 2 (2), 49–52. doi: https://doi.org/10.1016/j.bdr.2015.01.005

- Tang, L., Li, J., Du, H., Li, L., Wu, J., Wang, S. (2022). Big Data in Forecasting Research: A Literature Review. Big Data Research, 27, 100289. doi: https://doi.org/10.1016/j.bdr.2021.100289

- Fomin, O. V., Prokopenko, P. M., Burlutsky, O. V., Fomina, A. M. (2019). Control testing of freight wagon with the aim of assessing the residual resource of non-construction structures. Scientific Notes of Taurida National V.I. Vernadsky University. Series: Technical Sciences, 3 (2), 177–182. doi: https://doi.org/10.32838/2663-5941/2019.3-2/31

- Marinkovic, D., Zehn, M. (2019). Survey of Finite Element Method-Based Real-Time Simulations. Applied Sciences, 9 (14), 2775. doi: https://doi.org/10.3390/app9142775

- Cremonesi, M., Franci, A., Idelsohn, S., Oñate, E. (2020). A State of the Art Review of the Particle Finite Element Method (PFEM). Archives of Computational Methods in Engineering, 27 (5), 1709–1735. doi: https://doi.org/10.1007/s11831-020-09468-4

- Koshel, O. O., Kara, S. V., Hryndei, O. O. (2022). Mitsnisnyi analiz nyzhnoi ramy dumpkara (vahona-samoskyda) z metoiu vyznachennia mozhlyvosti prodovzhennia terminu ekspluatatsiyi. Scientific Collection «InterConf», 111, 439–444. Available at: https://archive.interconf.center/index.php/conference-proceeding/article/view/637

- Gil, D., Song, I.-Y. (2016). Modeling and Management of Big Data: Challenges and opportunities. Future Generation Computer Systems, 63, 96–99. doi: https://doi.org/10.1016/j.future.2015.07.019

- Koshel, O., Sapronova, S., Tkachenko, V., Buromenska, M., Radkevich, M. (2021). Research of Freight Cars Malfunctions in Operation. Proceedings of 25th International Scientific Conference. Transport Means 2021, 589–592. Available at: https://transportmeans.ktu.edu/wp-content/uploads/sites/307/2018/02/Transport-Means-2021-Part-II.pdf

- Koshel, O., Sapronova, S., Bulich, D., Tkachenko, V. (2020). Determination of the Load-Bearing Metal Structures Residual Operation Time of the Ukraine Railway. Proceedings of 24th International Scientific Conference. Transport Means 2020, 228–232. Available at: https://transportmeans.ktu.edu/wp-content/uploads/sites/307/2018/02/Transport-means-A4-I-dalis.pdf

- Koshel, O. (2022). Varianty vidnovlennia nyzhnoi ramy dumpkara (vahona-samoskyda) z metoiu podalshoi mozhlyvosti prodovzhennia terminu ekspluatatsiyi. Scientific Collection «InterConf+», 22 (113), 431–436. doi: https://doi.org/10.51582/interconf.19-20.06.2022.044

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleksii Koshel, Svitlana Sapronova, Serhii Kara

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.