Identifying of chemical composition changes during the carburizing process of carbon steel under tension

DOI:

https://doi.org/10.15587/1729-4061.2023.286199Keywords:

carbon steel, load tensile, carburizing, chemical composition, scanning electron microscopyAbstract

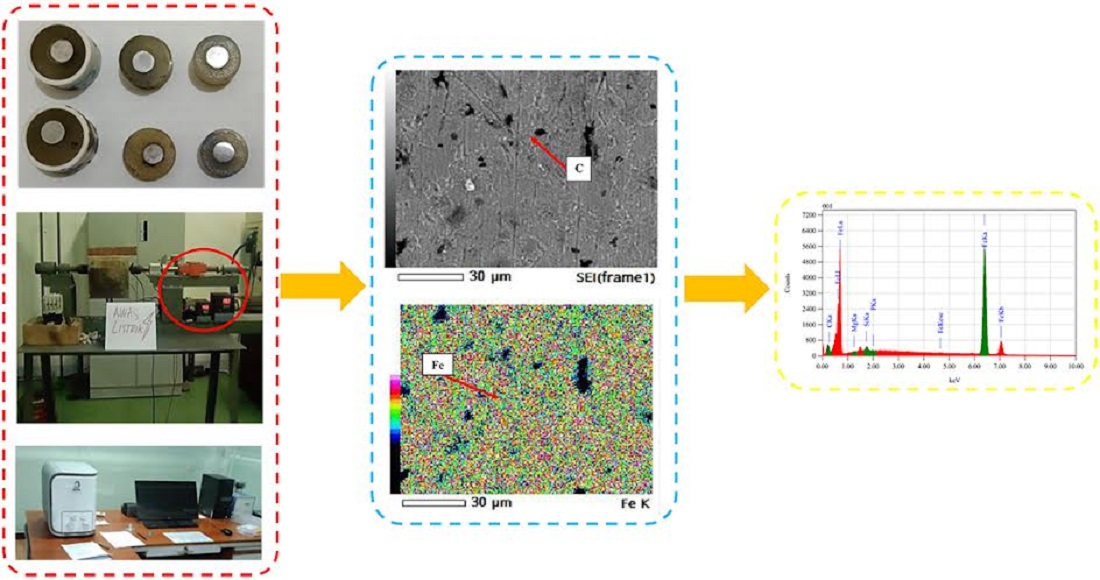

Carburizing is a commonly employed technique used to improve carbon steel’s surface characteristics, specifically its hardness and ability to resist wear. The introduction of tension during the carburizing process adds complexities that affect the distribution of elements in the material. The research methodology includes subjecting carbon steel samples to carburizing temperatures and applying tensile stress. This approach allows for analyzing the effects of carburization and stress on the carbon steel samples. The focus of the investigation was to analyze the use of the pack carburizing technique at lower temperatures, specifically 700 °C and 750 °C, while also applying proportional-voltage tensile stresses. The study focuses on conducting a comprehensive analysis of changes in the chemical composition throughout the cross-section of the material. Advanced analytical techniques perform mapping and elemental spectrum analysis, such as scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS). These techniques enable a thorough investigation of the distribution and composition of elements such as carbon, iron, silicon, magnesium, and phosphorus. According to the research findings, carbon elements were added within the temperature range of 700 °C to 750 °C during the carburization process. The carbon content in the material increased from 0.15 % in its unprocessed state to 0.73 % at a temperature of 700 °C, followed by a further increase to 1.26 % at a temperature of 750 °C. According to the study, it was found that applying tensile loads and reducing carburizing temperatures can enhance the carburizing process and result in higher carbon steel content. This can bring about cost savings and improve overall industrial efficiency

Supporting Agency

- The author expresses our sincere gratitude to the Department of Mechanical Engineering at Hasanuddin University in South Sulawesi for their valuable contribution and cooperation in facilitating the publishing of this research work.

References

- Riastuti, R., Mashanafie, G., Rizkia, V., Maksum, A., Prifiharni, S., Kaban, A. et al. (2022). Effect of syzygium cumini leaf extract as a green corrosion inhibitor on API 5l carbon steel in 1M HCL. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 30–41. doi: https://doi.org/10.15587/1729-4061.2022.267232

- Lan, L., Yu, M., Qiu, C. (2019). On the local mechanical properties of isothermally transformed bainite in low carbon steel. Materials Science and Engineering: A, 742, 442–450. doi: https://doi.org/10.1016/j.msea.2018.11.011

- Boumerzoug, Z., Derfouf, C., Baudin, T. (2010). Effect of Welding on Microstructure and Mechanical Properties of an Industrial Low Carbon Steel. Engineering, 02 (07), 502–506. doi: https://doi.org/10.4236/eng.2010.27066

- Putra Negara, D. N. K., Tirta Nindhia, T. G., Surata, I. W., Sucipta, M. (2017). Chemical, strength and microstructure characterization of Balinese bamboos as activated carbon source for adsorbed natural gas application. IOP Conference Series: Materials Science and Engineering, 201, 012033. doi: https://doi.org/10.1088/1757-899x/201/1/012033

- Bontong, Y., Nitha, H. A., Syam, R., Arsyad, H., Asmal, H. S. (2018). Behavior of pack carburizing with bone buffalo charcoal and BaCO3 against mechanical properties of low carbon steel. ARPN Journal of Engineering and Applied Sciences, 13 (14), 4309–4316. Available at: https://www.academia.edu/42713028/BEHAVIOR_OF_PACK_CARBURIZING_WITH_BONE_BUFFALO_CHARCOAL_AND_BACO3_AGAINST_MECHANICAL_PROPERTIES_OF_LOW_CARBON_STEEL

- Ashby, M. F., Jones, D. R. H. (2012). Engineering materials 1: an introduction to properties, applications and design. Elsevier. doi: https://doi.org/10.1016/c2009-0-64288-4

- Dragatsis, A., Fragkos-Livanios, L., Papageorgiou, D. G., Medrea, C. (2021). Investigation of hardness behavior after carburizing and hardening of 15CrNi6 steel. MATEC Web of Conferences, 349, 02006. doi: https://doi.org/10.1051/matecconf/202134902006

- Zhang, X., Zhang, G., Zhang, D., Zhang, L., Qian, F. (2023). Dynamic Multi-Objective Optimization in Brazier-Type Gasification and Carbonization Furnace. Materials, 16 (3), 1164. doi: https://doi.org/10.3390/ma16031164

- Sinarep, S., Darmo, S. (2021). Effect of pack carburizing with chicken egg shell powder agent and vibrator quenching on the mechanical properties of AISI 9310 steel. Eastern-European Journal of Enterprise Technologies, 6 (12 (114)), 12–19. doi: https://doi.org/10.15587/1729-4061.2021.244118

- Putra Negara, D. N. K., Muku, I. D. M. K., Sugita, I. K. G., Astika, I. M., Mustika, I. W., Prasetya, D. G. R. (2015). Hardness Distribution and Effective Case Depth of Low Carbon Steel after Pack Carburizing Process under Different Carburizer. Applied Mechanics and Materials, 776, 201–207. doi: https://doi.org/10.4028/www.scientific.net/amm.776.201

- Subbiah, R., Vinod Kumar, V., Lakshmi Prasanna, G. (2020). Wear analysis of treated Duplex Stainless Steel material by carburizing process – A review. Materials Today: Proceedings, 26, 2946–2952. doi: https://doi.org/10.1016/j.matpr.2020.02.608

- Han, R. D., Hu, K. H., Rolfe, B., Pavlina, E. (2016). A Research on Selective Carburization Process of Low Carbon Steel. Advanced High Strength Steel and Press Hardening. doi: https://doi.org/10.1142/9789813140622_0012

- Abdulrazzaq, M. A. (2016). Investigation the mechanical properties of carburized low carbon steel. Int. Journal of Engineering Research and Application, 6 (9), 59–65. Available at: https://www.academia.edu/28504474/Investigation_The_Mechanical_Properties_of_Carburized_Low_Carbon_Steel

- Ngafwan, Anggonor, A. D., Pramanda, W., Purnomo (2021). The Influence of Carbon Particle Size in The Carburizing Process of ST-40 Steel to The Surface Hardness. Journal of Physics: Conference Series, 1858 (1), 012026. doi: https://doi.org/10.1088/1742-6596/1858/1/012026

- Satito, A., Hariyanto, H., Supandi, S. (2021). Biaxial pressure pack carburizing method to modification local low carbon steel’s mechanical properties. IOP Conference Series: Materials Science and Engineering, 1108 (1), 012036. doi: https://doi.org/10.1088/1757-899x/1108/1/012036

- Priadi, D., Setyadi, I., Siradj, E. (2010). Influence of Strain Rate and Temperature of Hot Tension Testing on Mechanical Properties of Medium Carbon Steel S48C. Makara Journal of Technology, 7 (1). doi: https://doi.org/10.7454/mst.v7i1.137

- Jiang, Y., Li, Y., Peng, Y., Gong, J. (2020). Mechanical properties and cracking behavior of low-temperature gaseous carburized austenitic stainless steel. Surface and Coatings Technology, 403, 126343. doi: https://doi.org/10.1016/j.surfcoat.2020.126343

- Priyadarshini, S., Sharma, T., Arora, G. (2014). Effect of Post Carburizing Treatment on Hardness of Low Carbon Steel. Int. J. Adv. Mech. Eng, 4 (7), 763–766. Available at: https://www.ripublication.com/ijame-spl/ijamev4n7spl_07.pdf

- Smallman, R. E., Bishop, R. J. (1999). Modern physical metallurgy and materials engineering. Butterworth-Heinemann. doi: https://doi.org/10.1016/b978-0-7506-4564-5.x5000-9

- Callister Jr, W. D., Rethwisch, D. G. (2007). Materials science and engineering an introduction. Wiley.

- Oyetunji, A., Adeosun, S. O. (2021). Effects of Carburizing Process Variables on Mechanical and Chemical Properties of Carburized Mild Steel. Journal of Basic & Applied Sciences, 8 (2), 319–324. doi: https://doi.org/10.6000/1927-5129.2012.08.02.11

- Elzanaty, H. (2014). Effect of carburization on the mechanical properties of the mild steel. International Journal of Innovation and Applied Studies, 6 (4), 987–994. Available at: https://www.issr-journals.org/xplore/ijias/0006/004/IJIAS-14-153-05.pdf

- Wei, S., Wang, G., Zhao, X., Zhang, X., Rong, Y. (2013). Experimental Study on Vacuum Carburizing Process for Low-Carbon Alloy Steel. Journal of Materials Engineering and Performance, 23 (2), 545–550. doi: https://doi.org/10.1007/s11665-013-0762-1

- Yao, J., Zhang, Q., Gao, M., Zhang, W. (2008). Microstructure and wear property of carbon nanotube carburizing carbon steel by laser surface remelting. Applied Surface Science, 254 (21), 7092–7097. doi: https://doi.org/10.1016/j.apsusc.2008.05.223

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nitha, Onny S. Sutresman, Ahmad Yusran Aminy, Lukmanul Hakim Arma

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.