Devising technological solutions for gas sensors based on zinc oxide for use at critical infrastructure facilities

DOI:

https://doi.org/10.15587/1729-4061.2023.286546Keywords:

ZnO, gas sensor, magnetron sputtering, operating temperature, sensitivity, reaction stabilityAbstract

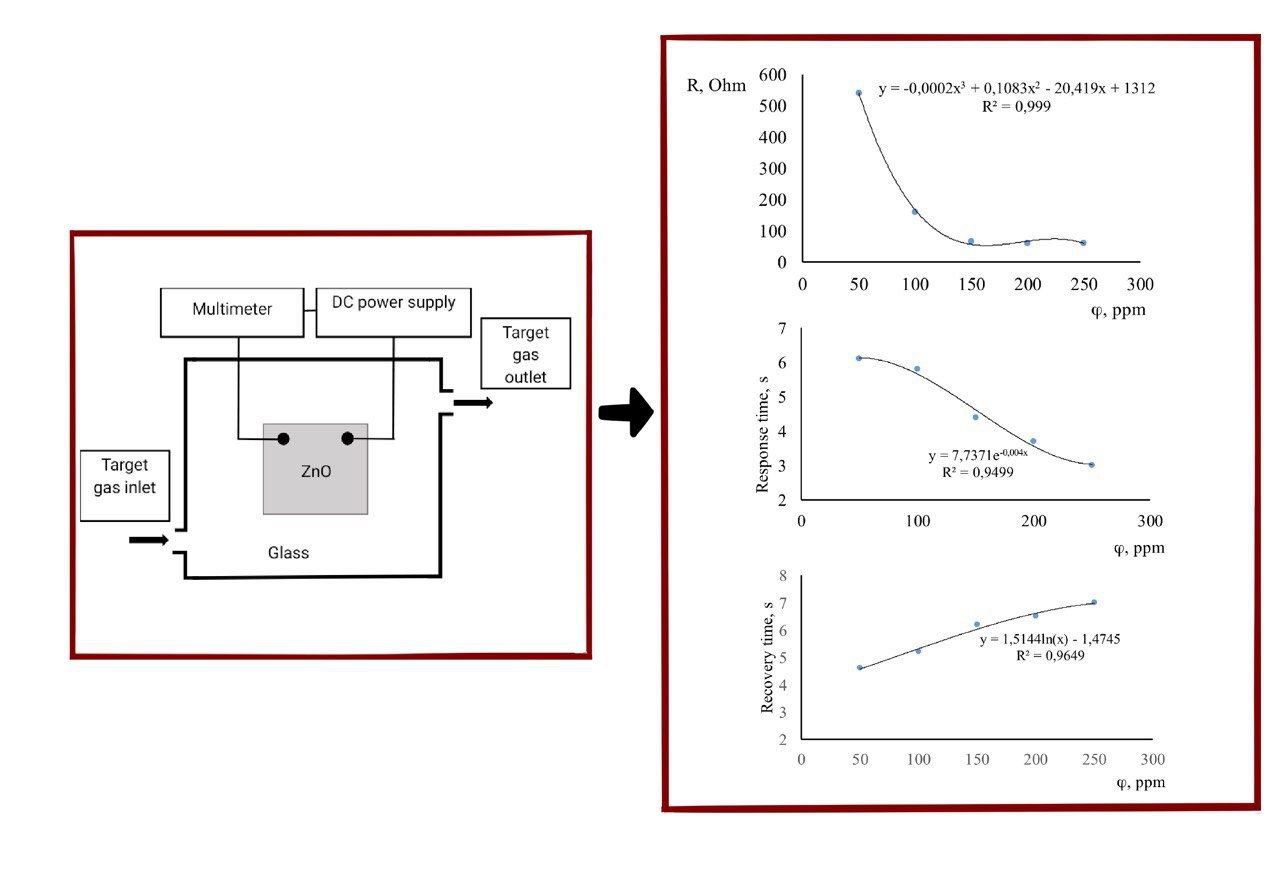

This paper reports a study of a gas sensor based on nanostructured zinc oxide in order to establish the conditions for its production and operating characteristics under the influence of the target gas ethanol. The studied samples were produced by magnetron sputtering on direct current. The method of forming the device structure was chosen among others due to the fact that it has a high rate of deposition at low values of the working gas pressure, there is no overheating of the substrate, a low degree of contamination of the obtained films, the possibility of obtaining samples of uniform thickness on a large area of the substrate. A VUP-5M vacuum unit with an original material-saving magnetron was used to obtain the films. Studies of the effect of temperature on the resistance of a gas sensor based on ZnO have been carried out. It was established that the change in the resistance of the tested sample depends on the temperature of the substrate. The resistance of the gas sensor in atmospheric air decreases with increasing substrate temperature from room temperature (25 °C) to 200 °C. A further increase in temperature from 200 °C leads to an increase in the resistance of the structure until it stabilizes in the temperature range of 300–400 °C. It was established that the operating temperature range of the gas sensor based on ZnO is within 300–400 °C. The characteristics of the gas sensor based on ZnO were studied and the working temperature of the sensor was determined for the rapid identification of ethanol in atmospheric air at a target gas concentration of 500 ppm. It was established that for rapid operation of the instrument structure, the temperature of the substrate should be 400 °C, a decrease or increase in temperature leads to a decrease in the sensitivity of the sensor to the target gas. It was established that the gas sensor demonstrates stability and a consistent sensitivity response upon repeated exposure to the target gas

References

- Vambol, S., Vambol, V., Sobyna, V., Koloskov, V., Poberezhna, L. (2019). Investigation of the energy efficiency of waste utilization technology, with considering the use of low-temperature separation of the resulting gas mixtures. Energetika, 64 (4). doi: https://doi.org/10.6001/energetika.v64i4.3893

- Chernukha, A., Teslenko, A., Kovalov, P., Bezuglov, O. (2020). Mathematical Modeling of Fire-Proof Efficiency of Coatings Based on Silicate Composition. Materials Science Forum, 1006, 70–75. doi: https://doi.org/10.4028/www.scientific.net/msf.1006.70

- Kovalov, A., Otrosh, Y., Rybka, E., Kovalevska, T., Togobytska, V., Rolin, I. (2020). Treatment of Determination Method for Strength Characteristics of Reinforcing Steel by Using Thread Cutting Method after Temperature Influence. Materials Science Forum, 1006, 179–184. doi: https://doi.org/10.4028/www.scientific.net/msf.1006.179

- Sadkovyi, V., Andronov, V., Semkiv, O., Kovalov, A., Rybka, E., Otrosh, Yu. et. al.; Sadkovyi, V., Rybka, E., Otrosh, Yu. (Eds.) (2021). Fire resistance of reinforced concrete and steel structures. Kharkiv: РС ТЕСHNOLOGY СЕNTЕR, 180. doi: https://doi.org/10.15587/978-617-7319-43-5

- Pospelov, B., Kovrehin, V., Rybka, E., Krainiukov, O., Petukhova, O., Butenko, T. et al. (2020). Development of a method for detecting dangerous states of polluted atmospheric air based on the current recurrence of the combined risk. Eastern-European Journal of Enterprise Technologies, 5 (9 (107)), 49–56. doi: https://doi.org/10.15587/1729-4061.2020.213892

- Pospelov, B., Rybka, E., Krainiukov, O., Yashchenko, O., Bezuhla, Y., Bielai, S. et al. (2021). Short-term forecast of fire in the premises based on modification of the Brown’s zero-order model. Eastern-European Journal of Enterprise Technologies, 4 (10 (112)), 52–58. doi: https://doi.org/10.15587/1729-4061.2021.238555

- Neshpor, O., Deyneko, N., Ponomarenko, R., Maiboroda, A., Kropyva, M., Blyashenko, O. et al. (2022). Optimization of the technology for designing sensitive gas sensors based on zinc oxide using a sol-gel method. Eastern-European Journal of Enterprise Technologies, 4 (5 (118)), 30–36. doi: https://doi.org/10.15587/1729-4061.2022.263686

- Zhang, Y., Li, D., Qin, L., Zhao, P., Liu, F., Chuai, X. et al. (2018). Preparation and gas sensing properties of hierarchical leaf-like SnO2 materials. Sensors and Actuators B: Chemical, 255, 2944–2951. doi: https://doi.org/10.1016/j.snb.2017.09.115

- Kołodziejczak-Radzimska, A., Jesionowski, T. (2014). Zinc Oxide—From Synthesis to Application: A Review. Materials, 7 (4), 2833–2881. doi: https://doi.org/10.3390/ma7042833

- Lorenz, M., Ramachandra Rao, M. S., Venkatesan, T., Fortunato, E., Barquinha, P., Branquinho, R. et al. (2016). The 2016 oxide electronic materials and oxide interfaces roadmap. Journal of Physics D: Applied Physics, 49 (43), 433001. doi: https://doi.org/10.1088/0022-3727/49/43/433001

- Zhang, H., Babichev, A. V., Jacopin, G., Lavenus, P., Julien, F. H., Yu. Egorov, A. et al. (2013). Characterization and modeling of a ZnO nanowire ultraviolet photodetector with graphene transparent contact. Journal of Applied Physics, 114 (23). doi: https://doi.org/10.1063/1.4854455

- Xu, Q., Cheng, L., Meng, L., Wang, Z., Bai, S., Tian, X. et al. (2019). Flexible Self-Powered ZnO Film UV Sensor with a High Response. ACS Applied Materials & Interfaces, 11 (29), 26127–26133. doi: https://doi.org/10.1021/acsami.9b09264

- Mohan, A. C., Renjanadevi, B. (2016). Preparation of Zinc Oxide Nanoparticles and its Characterization Using Scanning Electron Microscopy (SEM) and X-Ray Diffraction(XRD). Procedia Technology, 24, 761–766. doi: https://doi.org/10.1016/j.protcy.2016.05.078

- Bian, H., Ma, S., Sun, A., Xu, X., Yang, G., Yan, S. et al. (2016). Improvement of acetone gas sensing performance of ZnO nanoparticles. Journal of Alloys and Compounds, 658, 629–635. doi: https://doi.org/10.1016/j.jallcom.2015.09.217

- Yan, H., Song, P., Zhang, S., Yang, Z., Wang, Q. (2016). Facile synthesis, characterization and gas sensing performance of ZnO nanoparticles-coated MoS2 nanosheets. Journal of Alloys and Compounds, 662, 118–125. doi: https://doi.org/10.1016/j.jallcom.2015.12.066

- Umar, A., Khan, M. A., Kumar, R., Algarni, H. (2018). Ag-Doped ZnO Nanoparticles for Enhanced Ethanol Gas Sensing Application. Journal of Nanoscience and Nanotechnology, 18 (5), 3557–3562. doi: https://doi.org/10.1166/jnn.2018.14651

- Zhang, D., Yang, Z., Li, P., Zhou, X. (2019). Ozone gas sensing properties of metal-organic frameworks-derived In2O3 hollow microtubes decorated with ZnO nanoparticles. Sensors and Actuators B: Chemical, 301, 127081. doi: https://doi.org/10.1016/j.snb.2019.127081

- Miasoiedova, A., Minska, N., Shevchenko, R., Azarenkо, O., Lukashenko, V., Kyrychenko, O. et al. (2023). Improving the manufacturing technology of sensing gas sensors based on zinc oxide by using the method of magnetron sputtering on direct current. Eastern-European Journal of Enterprise Technologies, 2 (5 (122)), 31–37. doi: https://doi.org/10.15587/1729-4061.2023.277428

- Khrypunov, G., Vambol, S., Deyneko, N., Sychikova, Y. (2016). Increasing the efficiency of film solar cells based on cadmium telluride. Eastern-European Journal of Enterprise Technologies, 6 (5 (84)), 12–18. doi: https://doi.org/10.15587/1729-4061.2016.85617

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Natalia Minska, Viktor Hvozd, Olga Shevchenko, Yevhen Slepuzhnikov, Rustam Murasov, Valerii Khrystych, Valery Strelets, Svitlana Kryvonis, Vasyl Rotar, Volodymyr Lypovyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.