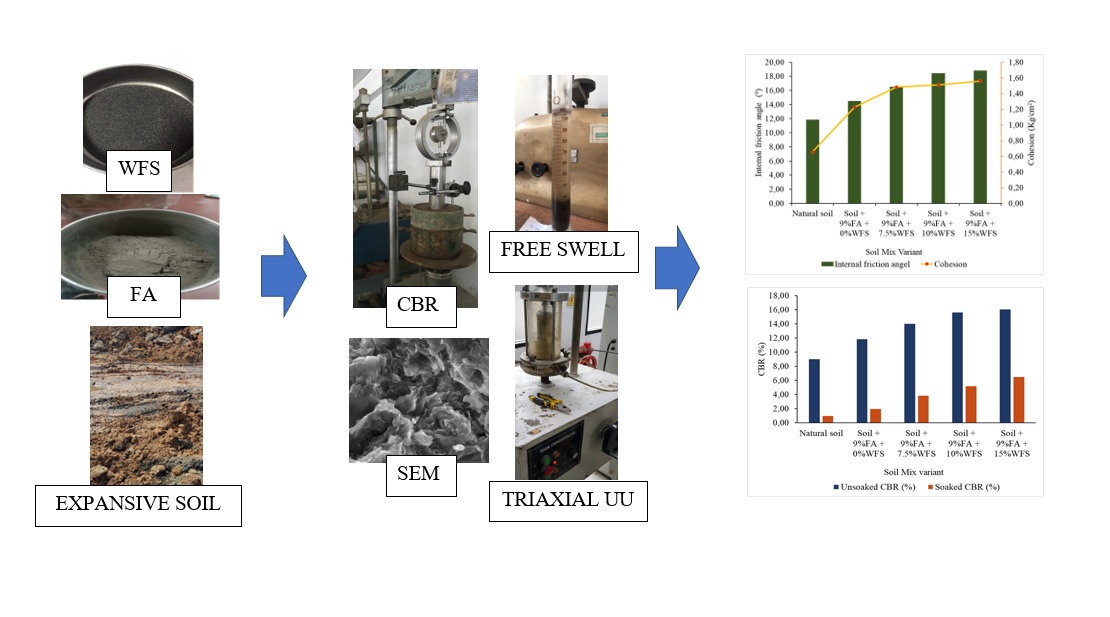

Identifying the microstructure and mechanical properties of expansive soil stabilized using fly ash and waste foundry sand

DOI:

https://doi.org/10.15587/1729-4061.2023.286991Keywords:

expansive soil, stabilization, WFS, FA, microstructureAbstract

Expansive soil causes road construction damage in the form of cracks or deformations due to changes in moisture content. One method to address this issue is soil stabilization using additive materials. Special additives can sometimes be expensive; hence it is necessary to use additive materials based on industrial waste as a waste management solution to solve the problem of expansive soil as a road construction subgrade. This study aims to analyze the effects of adding two types of industrial waste, namely fly ash (FA) and waste foundry sand (WFS), regarding the microstructure, physical, and mechanical properties of expansive soil. The method of stabilizing expansive soil involves mixing the soil with 9 % FA and various levels of WFS (0 %, 7.5 %, 10 %, 15 %) based on the dry weight of the soil. Microstructure testing includes quantitative X-ray diffraction and scanning electron microscopy. Physical property testing includes specific gravity, Atterberg limits and sieve analysis. Mechanical testing, i.e. compaction, California Bearing Ratio, swelling, and Triaxial tests were conducted. Soil stabilized with 9 % FA and 15 % WFS shows a significant increase in the internal friction angle and cohesion, reducing swelling by 67.18 % compared to the original soil swelling. The addition of 9 % fly ash and 15 % WFS to expansive soil reduces the content of montmorillonite. Natural expansive soils have a very poor soaked CBR of 0.94 %, while stabilized soils with 9 % FA and 15 % WFS have a soaked CBR of 6.46 %. This means that the soaked CBR of the stabilized soil meets the minimum CBR required for road subgrade construction. A mixture of 9 % FA and 15 % WFS in expansive soil can be recommended as a material for stabilizing expansive soil due to its ability to improve microstructure and mechanical properties

References

- Zhang, Y., Sappinen, T., Korkiala-Tanttu, L., Vilenius, M., & Juuti, E. (2021). Investigations into stabilized waste foundry sand for applications in pavement structures. Resources, Conservation and Recycling, 170, 105585.

- Sharma, A. K., & Sivapullaiah, P. V. (2016). Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils and Foundations, 56(2), 205-212.

- Zaika, Y., & Suryo, E. A. (2019). Design of improved lime expansive soil for embankment of flexible pavement. GEOMATE Journal, 17(60), 90-95.

- Indiramma, P., Sudharani, C., & Needhidasan, S. (2020). Utilization of fly ash and lime to stabilize the expansive soil and to sustain pollution free environment–An experimental study. Materials Today: Proceedings, 22, 694-700.

- Sudjianto, A. T., Suraji, A., & Susilo, S. H. (2021). Analysis of soil characteristics on expansive clay stabilization using shell ash. Eastern-European Journal of Enterprise Technologies, 6(6), 114.

- Blayi, R. A., Sherwani, A. F. H., Ibrahim, H. H., Faraj, R. H., & Daraei, A. (2020). Strength improvement of expansive soil by utilizing waste glass powder. Case Studies in Construction Materials, 13, e00427.

- Khadka, S. D., Jayawickrama, P. W., Senadheera, S., & Segvic, B. (2020). Stabilization of highly expansive soils containing sulfate using metakaolin and fly ash based geopolymer modified with lime and gypsum. Transportation Geotechnics, 23, 100327.

- Yadav, A. P., & Kumar, E. N. (2019). A Comparative Study of Waste Foundry Sand and Marble Dust for Stabilization of Subgrade Soil. International Journal for Research in Applied Science and.

- Mishra, B. (2014). A Study on characteristics of subgrade soil by use of foundry sand and Iron turnings. International Journal of Science and Research (IJSR), ISSN (Online), 2319-7064.

- Gunarti, A. S. S., & Raharja, I. (2020, May). Mechanical Properties Improvement of Clays Using Silica Sand Waste and Dust Sand Foundry Waste. In IOP Conference Series: Materials Science and Engineering (Vol. 856, No. 1, p. 012002). IOP Publishing.

- Gunarti, A. S. S., Nuryati, S., Muttaqin, P. A., & Raharja, I. (2020, April). Unconfined compression strength of soil using silica sand waste and dust sand foundry as a stabilizer. In Journal of Physics: Conference Series (Vol. 1517, No. 1, p. 012028). IOP Publishing.

- Venkatesh, J., Chinnusamy, K., & Murugesh, S. (2020, November). A Review Paper on Comparative study of Expansive Sub-Grade Stabilization using Industrial Wastes like Foundry Sand, Quarry Dust, Demolition Wastes and Rubber Scrap. In IOP Conference Series: Materials Science and Engineering (Vol. 955, No. 1, p. 012062). IOP Publishing.

- Bhardwaj, B., & Kumar, P. (2017). Waste foundry sand in concrete: A review. Construction and building materials, 156, 661-674.

- Moses, G., Saminu, A., & Oriola, F. O. P. (2012). Influence of compactive efforts on compacted foundry Sand treated with Cement Kiln dust. Civil and Environmental Research, 2(5), 11-24.

- Peter, L., Jayasree, P. K., Balan, K., & Raj, S. A. (2016). Laboratory investigation in the improvement of subgrade characteristics of expansive soil stabilised with coir waste. Transportation Research Procedia, 17, 558-566.

- Mohanty, S., Pradhan, P., & Mohanty, C. (2018). Stabilization of expansive soil using industrial waste: fly ash. Civil engineering research journal, 3(2).

- Cokca, E. (2001). Use of class c fly ashes for the stabilizationof an expansive soil. Journal of Geotechnical and Geoenvironmental Engineering, 127(7), 568-573.

- Zha, F., Liu, S., Du, Y., & Cui, K. (2008). Behavior of expansive soils stabilized with fly ash. Natural hazards, 47, 509-523.

- Zumrawi, M. M. (2015). Stabilization of Pavement Subgrade by Using Fly Ash Activated by Cement. American Journal of Civil Engineering and Architecture, 3(6), 218-224.

- Sabat, A. K., & Pradhan, A. (2014). Fiber reinforced-fly ash stabilized expansive soil mixes as subgrade material in flexible pavement. Electronic Journal of Geotechnical Engineering, 19, 5757-5770.

- Bose, B. (2012). Geo engineering properties of expansive soil stabilized with fly ash. Electronic Journal of Geotechnical Engineering, 17(1), 1339-1353.

- Razvi, S., Sujahat, S., Adnan, S., Aasim, K., Ravi, U., & Saud, M. (2007). Stabilization of Soil by Foundry Sand with Fly-Ash. Int. J. Innov. Res. Sci. Eng. Technol.(An ISO, 3297(5), 9449-9454.

- Sharma, R. K., & Kumar, A. (2013). Compaction and Sub-grade Characteristics of Clayey Soil Mixed with Foundry Sand and Fly Ash. International Journal of Engineering Research & Technology (IJERT), 2(10), 1504-1509.

- Seed, H. B., Woodward Jr, R. J., & Lundgren, R. (1962). Prediction of swelling potential for compacted clays. Journal of the soil mechanics and foundations division, 88(3), 53-87.

- Chen, F. H. (1975). Developments in geotechnical engineering: Foundations on expansive soils. Elsevier Scientific Publishing Company.

- Bose, B. (2012). Geo engineering properties of expansive soil stabilized with fly ash. Electronic Journal of Geotechnical Engineering, 17(1), 1339-1353.

- Khare, A., Gupta, S. K., Sah, S., Kumar, M., Toppo, A., Jain, A., & Jaiswal, S. K. (2023). Implication of Fly Ash in Stabilizing Expansive Soil. Intersect: The Stanford Journal of Science, Technology, and Society, 16(2).

- Turan, C., Javadi, A. A., Vinai, R., & Beig Zali, R. (2022). Geotechnical characteristics of fine-grained soils stabilized with fly ash, a review. Sustainability, 14(24), 16710.

- Zimar, Z., Robert, D., Zhou, A., Giustozzi, F., Setunge, S., & Kodikara, J. (2022). Application of coal fly ash in pavement subgrade stabilisation: A review. Journal of Environmental Management, 312, 114926.

- Kaur, M. (2019). Improvement Of Cbr Value Of Expansive Soil With Industrial Waste. Journal of emergng Technologies and Innovative Research, 6(5).

- Soni, A., & Varshney, D. (2021, April). Enhancing the california bearing ratio (CBR) value of clayey-sand type of soil in mathura region. In IOP Conference Series: Materials Science and Engineering (Vol. 1116, No. 1, p. 012031). IOP Publishing.

- Rajakumar, C., & Meenambal, T. (2015). CBR and UCC strength characteristics of expansive soil subgrade stabilized with industrial and agricultural wastes. International Journal of ChemTech Research, 8(7), 1-17.

- Lakshmi, S. M., Geetha, S., & Selvakumar, M. (2021). Predicting soaked CBR of SC subgrade from dry density for light and heavy compaction. Materials Today: Proceedings, 45, 1664-1670.

- Choudhary, A. K., Gill, K. S., & Jha, J. N. (2011). Improvement in CBR values of expansive soil subgrades using Geo synthetics. Guru Nanak Dev Engineering College Ludhiana (Punjab)-141006, 155.

- Warsiti, W., Kusdiyono, K., Risman, R., & Ristiawan, A. (2020). Characteristic Study of CBR Value of Red Soil Mixture with Lime. Bangun Rekaprima: Majalah Ilmiah Pengembangan Rekayasa, Sosial dan Humaniora, 6(1, April), 58-68.

- Sithole, N. T., Tsotetsi, N. T., Mashifana, T., & Sillanpää, M. (2022). Alternative cleaner production of sustainable concrete from waste foundry sand and slag. Journal of Cleaner Production, 336, 130399.

- 37Kumar, P., Paliwal, M.C., Jain. A.K. (2016) Stabilization Of Sub Grade Soil By Using Foundry Sand Waste. International journal of engineering sciences & research technology, 5(9)

- Bell, F. G. (1996). Lime stabilization of clay minerals and soils. Engineering geology, 42(4), 223-237.

- Gorakhki, M. H., Alhomair, S. A., & Bareither, C. A. (2017). Re-Use of Mine Waste Materials Amended with Fly Ash in Transportation Earthworks Projects (No. MPC 17-332). Research Report–MPC Publications: MPC-17-332. North Dakota State University-Upper Great Plains Transportation Institute, Fargo: Mountain-Plains Consortium.

- Zhou, S. Q., Zhou, D. W., Zhang, Y. F., & Wang, W. J. (2019). Study on physical-mechanical properties and microstructure of expansive soil stabilized with fly ash and lime. Advances in Civil Engineering, 2019.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Anita Setyowati Srie Gunarti, Yulvi Zaika, As’ad Munawir, Eko Andi Suryo, Harimurti

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.