Ensuring the stability of machining when using end mills

DOI:

https://doi.org/10.15587/1729-4061.2023.287009Keywords:

end milling, stability of the cutting process, identification of dynamic parameters of the machining system, stability lobes diagramAbstract

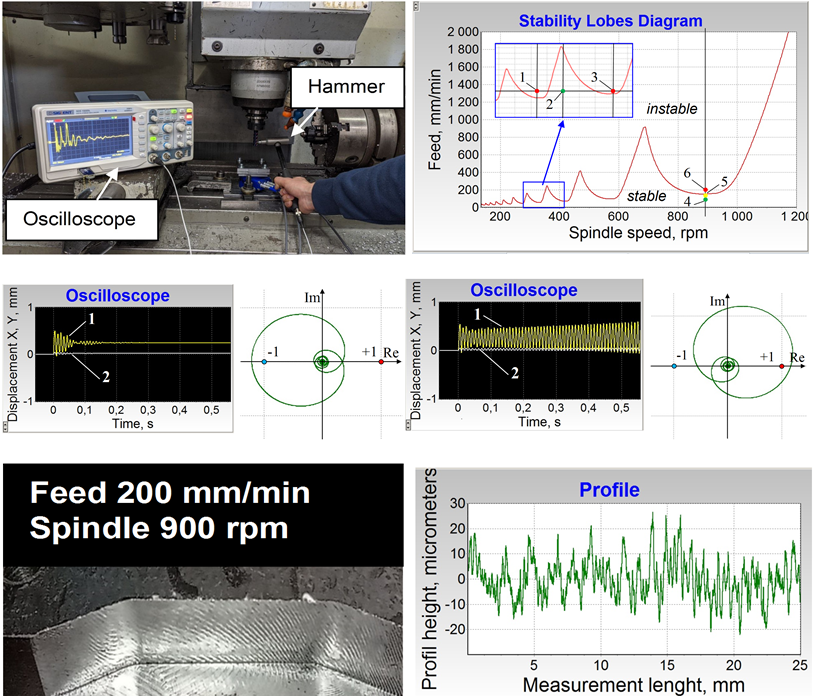

This paper reports a new approach to ensuring the stability of the end milling process, due to vibration-free cutting modes, which are determined from the stability lobes diagram of the dynamic machining system. An application program for automatic calculation of the stability lobes diagram in the coordinates «mill spindle speed – feed» has been developed, which is a tool for the technologist-programmer when designing control program for numerically controlled machines. The mathematical model underlying the application program represents a dynamic machining system as a single-mass system with two degrees of freedom, covered by negative feedback in the direction of two coordinates. The trailing machining is represented as positive feedback loops with a delay function in each. The mathematical model is given in the form of state variables, which allows applying numerical modeling methods to determine both transient and frequency responses. The software developed includes a separate module for automatic design of the stability lobes diagram whose algorithm uses the features of the location of the Nyquist diagram on the complex plane. Since the functioning of the developed program requires a priori information about the dynamic parameters of the machining system, a procedure for their experimental identification is presented. The stiffness of the machining system in two coordinates was determined with the help of a dynamometer, and the frequency responses were determined by the impulse response function, which was obtained with an impact hammer. The research results were confirmed experimentally both by computer simulation and milling on a machine tool and could be recommended for determining the cutting mode at end milling

References

- Quintana, G., Ciurana, J. (2011). Chatter in machining processes: A review. International Journal of Machine Tools and Manufacture, 51 (5), 363–376. doi: https://doi.org/10.1016/j.ijmachtools.2011.01.001

- Yue, C., Gao, H., Liu, X., Liang, S. Y., Wang, L. (2019). A review of chatter vibration research in milling. Chinese Journal of Aeronautics, 32 (2), 215–242. doi: https://doi.org/10.1016/j.cja.2018.11.007

- Altintas, Y. (2012). Manufacturing Automation. Cambridge: Cambridge University Press. doi: https://doi.org/10.1017/cbo9780511843723

- Koh, M. H. (2012). Identification of system parameters for end milling force simulation with tool and workpiece compliance. University of New Hampshire, 761. Available at: https://scholars.unh.edu/thesis/761/

- Xia, Y., Wan, Y., Luo, X., Liu, Z., Song, Q. (2021). An improved numerical integration method to predict the milling stability based on the Lagrange interpolation scheme. The International Journal of Advanced Manufacturing Technology, 116 (7-8), 2111–2123. doi: https://doi.org/10.1007/s00170-021-07311-z

- Petrakov, Y., Sikailo, M. (2022). Simulation modeling of 2.5D milling dynamics by end mills. Bulletin of the National Technical University «KhPI» Series: New Solutions in Modern Technologies, 2 (12), 17–24. doi: https://doi.org/10.20998/2413-4295.2022.02.03

- Sreenivasa Rao, A., Venkata Rao, K. (2017). A Study on Machining Characteristics in Milling of Ti-6Al-4V using Experimental and Finite Element Analysis. International Journal of Civil Engineering and Technology, 8 (7), 457–469. Available at: http://iaeme.com/Home/issue/IJCIET?Volume=8&Issue=7

- Li, H. Z., Zhang, W. B., Li, X. P. (2001). Modelling of cutting forces in helical end milling using a predictive machining theory. International Journal of Mechanical Sciences, 43 (8), 1711–1730. doi: https://doi.org/10.1016/s0020-7403(01)00020-0

- Stephenson, D. A., Agapiou, J. S. (2018). Metal Cutting Theory and Practice. CRC Press. doi: https://doi.org/10.1201/9781315373119

- Quintana, G., Ciurana, J., Teixidor, D. (2008). A new experimental methodology for identification of stability lobes diagram in milling operations. International Journal of Machine Tools and Manufacture, 48 (15), 1637–1645. doi: https://doi.org/10.1016/j.ijmachtools.2008.07.006

- Petrakov, Y., Danylchenko, M. (2022). A time-frequency approach to ensuring stability of machining by turning. Eastern-European Journal of Enterprise Technologies, 6 (2 (120)), 85–92. doi: https://doi.org/10.15587/1729-4061.2022.268637

- Liang, S. Y. (2000). Manufacturing processes and equipment. Machining Science and Technology, 4 (2), 317–318. doi: https://doi.org/10.1080/10940340008945713

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuri Petrakov, Olexander Ohrimenko, Maxim Sikailo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.