Deformation features of trunk pipelines with composite linings under static loads

DOI:

https://doi.org/10.15587/1729-4061.2023.287025Keywords:

steel pipeline, pipe reinforcement, carbon fiber reinforced plastic bandage, finite element analysisAbstract

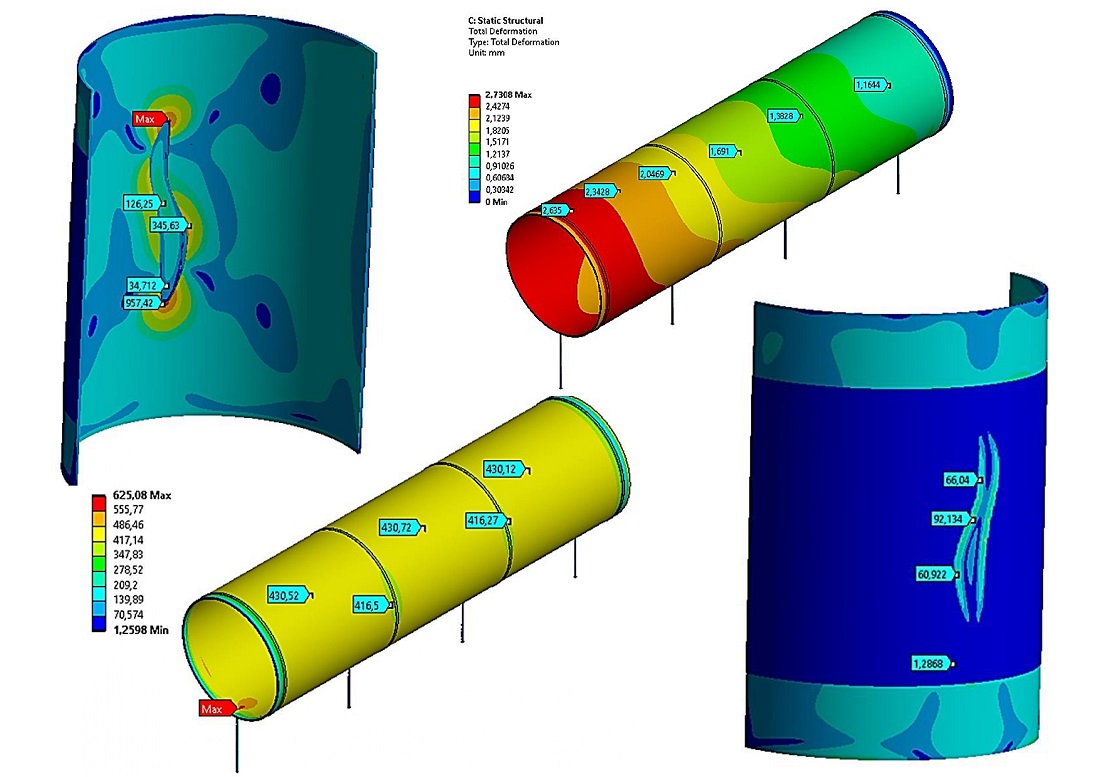

This paper considers the deformation process of a typical section of a steel trunk pipeline with a defective zone, strengthened with a carbon fiber composite lining, under the influence of stationary internal pressure. Defects in the form of thinning of the pipe thickness and cracks were investigated. The stressed-strained state of the structure at critical pressure was analyzed. The thickness of the composite lining was determined, at which the bandage compensates for the effect of internal pressure on the damaged section of the pipeline. Research was carried out numerically based on finite element modeling in the ANSYS software package.

When studying the stressed-strained state of a pipe with a defect of an arbitrary complex shape under the influence of critical pressure, a compensating value was obtained. The result showed that a carbon fiber lining with a thickness of 17 % of the rated thickness of the pipe could completely compensate for the effects of internal pressure in the defect area. In this case, the stresses in the carbon fiber lining were close to minimal. When studying the stressed-strained state of a pipe with a large crack of arbitrary shape at critical pressure, a compensating value was also obtained.

It has been established that to compensate for the concentration of internal pressure in the crack zone, the thickness of the composite lining should be at the level of 34 % of the rated thickness of the pipe. In this case, the deformation of the steel pipe in the area of the crack occurs in the elastic region. The exception is the crack tips, where plastic deformations are observed, and stresses arise up to 93 % of the ultimate strength of the pipe steel. At the same time, the stresses in the carbon fiber lining remain close to minimal. Thus, it is recommended to use carbon fiber linings with a thickness of 17 % or more of the rated pipe thickness to bandage damage constituting up to 75 % of the thickness of a steel pipe. To bandage cracks, it is recommended to use carbon fiber linings with a thickness of at least 34 % of the rated pipe thickness

References

- Vishnuvardhan, S., Murthy, A. R., Choudhary, A. (2023). A review on pipeline failures, defects in pipelines and their assessment and fatigue life prediction methods. International Journal of Pressure Vessels and Piping, 201, 104853. doi: https://doi.org/10.1016/j.ijpvp.2022.104853

- Suleimenov, U., Zhangabay, N., Abshenov, K., Utelbayeva, A., Imanaliyev, K., Mussayeva, S. et al. (2022). Estimating the stressed-strained state of the vertical mounting joint of the cylindrical tank wall taking into consideration imperfections. Eastern-European Journal of Enterprise Technologies, 3 (7 (117)), 14–21. doi: https://doi.org/10.15587/1729-4061.2022.258118

- Muda, M. F., Mohd Hashim, M. H., Kamarudin, M. K., Mohd, M. H., Tafsirojjaman, T., Rahman, M. A., Paik, J. K. (2022). Burst pressure strength of corroded subsea pipelines repaired with composite fiber-reinforced polymer patches. Engineering Failure Analysis, 136, 106204. doi: https://doi.org/10.1016/j.engfailanal.2022.106204

- Tursunkululy, T., Zhangabay, N., Avramov, K., Chernobryvko, M., Suleimenov, U., Utelbayeva, A. et al. (2022). Strength analysis of prestressed vertical cylindrical steel oil tanks under operational and dynamic loads. Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 14–21. doi: https://doi.org/10.15587/1729-4061.2022.254218

- Reis, J. M. L., Menezes, E. M., da Costa Mattos, H. S., Carbas, R. J. C., Marques, E. A., Silva, L. F. M. (2023). Strength of dissimilar adhesively bonded DCB joints and its connection with the failure pressure of composite repair systems. Composite Structures, 304, 116441. doi: https://doi.org/10.1016/j.compstruct.2022.116441

- Avramov, K. V., Uspensky, B. V., Derevyanko, I. I., Degtyaryov, M. O., Polishchuk, O. F., Chernobryvko, M. V. (2023). Dynamic properties of nanocomposite and three-layer thin-walled aerospace elements manufactured by additive technologies. Kosmìčna Nauka ì Tehnologìâ, 29 (1), 52–64. doi: https://doi.org/10.15407/knit2023.01.052

- Zhao, J., Lv, Y.-R., Cheng, Y. F. (2022). Standards and methods for dent assessment and failure prediction of pipelines: A critical review. Petroleum Science, 19 (6), 3029–3045. doi: https://doi.org/10.1016/j.petsci.2022.10.003

- Kec, J., Cerny, I. (2017). Stress-strain assessment of dents in wall of high pressure gas pipeline. Procedia Structural Integrity, 5, 340–346. doi: https://doi.org/10.1016/j.prostr.2017.07.180

- Zhao, P., Shuai, J., Sun, M., Lv, Z., Xu, K., Wang, Y. (2021). Burst pressure of thin-walled pipes with dent and gouge defects. Thin-Walled Structures, 159, 107213. doi: https://doi.org/10.1016/j.tws.2020.107213

- He, Z., Zhou, W. (2021). Fatigue reliability analysis of dented pipelines. Journal of Pipeline Science and Engineering, 1 (3), 290–297. doi: https://doi.org/10.1016/j.jpse.2021.08.004

- Shirazi, H., Eadie, R., Chen, W. (2023). A review on current understanding of pipeline circumferential stress corrosion cracking in near-neutral PH environment. Engineering Failure Analysis, 148, 107215. doi: https://doi.org/10.1016/j.engfailanal.2023.107215

- Niazi, H., Eadie, R., Chen, W., Zhang, H. (2021). High pH stress corrosion cracking initiation and crack evolution in buried steel pipelines: A review. Engineering Failure Analysis, 120, 105013. doi: https://doi.org/10.1016/j.engfailanal.2020.105013

- Qin, G., Cheng, Y. F. (2021). A review on defect assessment of pipelines: Principles, numerical solutions, and applications. International Journal of Pressure Vessels and Piping, 191, 104329. doi: https://doi.org/10.1016/j.ijpvp.2021.104329

- Tursunkululy, T., Zhangabay, N., Avramov, K., Chernobryvko, M., Kambarov, M., Abildabekov, A. et al. (2023). Oscillation frequencies of the reinforced wall of a steel vertical cylindrical tank for petroleum products depending on winding pre-tension. Eastern-European Journal of Enterprise Technologies, 3 (7 (123)), 14–25. doi: https://doi.org/10.15587/1729-4061.2023.279098

- Altenbach, H., Breslavsky, D., Chernobryvko, M., Senko, A., Tatarinova, O. (2022). Fast Fracture of Conic Shell Under the Action of Belt Explosive Charge. Advances in Mechanical and Power Engineering, 366–376. doi: https://doi.org/10.1007/978-3-031-18487-1_37

- Tursunkululy, T., Zhangabay, N., Avramov, K., Chernobryvko, M., Suleimenov, U., Utelbayeva, A. (2022). Influence of the parameters of the pre-stressed winding on the oscillations of vertical cylindrical steel oil tanks. Eastern-European Journal of Enterprise Technologies, 5 (7 (119)), 6–13. doi: https://doi.org/10.15587/1729-4061.2022.265107

- Tursunkululy, T., Zhangabay, N., Suleimenov, U., Abshenov, K., Utelbayeva, A., Moldagaliyev, A. et al. (2023). Analysis of strength and eigenfrequencies of a steel vertical cylindrical tank without liquid, reinforced by a plain composite thread. Case Studies in Construction Materials, 18, e02019. doi: https://doi.org/10.1016/j.cscm.2023.e02019

- Chernobryvko, M. V., Avramov, K. V., Romanenko, V. N., Batutina, T. J., Suleimenov, U. S. (2015). Dynamic instability of ring-stiffened conical thin-walled rocket fairing in supersonic gas stream. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 230 (1), 55–68. doi: https://doi.org/10.1177/0954406215592171

- Chernobryvko, M. V., Avramov, K. V., Romanenko, V. N., Batutina, T. J., Tonkonogenko, A. M. (2014). Free linear vibrations of thin axisymmetric parabolic shells. Meccanica, 49 (12), 2839–2845. doi: https://doi.org/10.1007/s11012-014-0027-6

- Alabtah, F. G., Mahdi, E., Eliyan, F. F. (2021). The use of fiber reinforced polymeric composites in pipelines: A review. Composite Structures, 276, 114595. doi: https://doi.org/10.1016/j.compstruct.2021.114595

- Lim, K. S., Azraai, S. N. A., Noor, N. M., Yahaya, N. (2016). An Overview of Corroded Pipe Repair Techniques Using Composite Materials. World Acad. Sci. Eng. Technol. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng., 10 (1), 19–25. doi: https://doi.org/10.5281/zenodo.1110684

- Dong, C. (2021). Flexural behaviour of carbon and glass reinforced hybrid composite pipes. Composites Part C: Open Access, 4, 100090. doi: https://doi.org/10.1016/j.jcomc.2020.100090

- Kong, D., Huang, X., Xin, M., Xian, G. (2020). Effects of defect dimensions and putty properties on the burst performances of steel pipes wrapped with CFRP composites. International Journal of Pressure Vessels and Piping, 186, 104139. doi: https://doi.org/10.1016/j.ijpvp.2020.104139

- Suleimenov, U., Zhangabay, N., Utelbayeva, A., Ibrahim, M. N. M., Moldagaliyev, A., Abshenov, K. et al. (2021). Determining the features of oscillations in prestressed pipelines. Eastern-European Journal of Enterprise Technologies, 6 (7 (114)), 85–92. doi: https://doi.org/10.15587/1729-4061.2021.246751

- Ibraimova, U., Zhangabay, N., Tursunkululy, T., Rakhimov, M., Dossybekov, S., Kolesnikov, A. et al. (2023). Development of method for calculation of pre-strained steel cylindrical sheaths in view of the winding angle, pitch and thickness. Case Studies in Construction Materials, 19, e02233. doi: https://doi.org/10.1016/j.cscm.2023.e02233

- Zhangabay, N., Sapargaliyeva, B., Utelbayeva, A., Kolesnikov, A., Aldiyarov, Z., Dossybekov, S. et al. (2022). Experimental Analysis of the Stress State of a Prestressed Cylindrical Shell with Various Structural Parameters. Materials, 15 (14), 4996. doi: https://doi.org/10.3390/ma15144996

- SP RK EN 1998-4:2006/2012. Proektirovanie seysmostoykikh konstruktsiy. Chast' 4. Bunkery, rezervuary i truboprovody. Available at: https://online.zakon.kz/Document/?doc_id=37105813&doc_id2=37807474#activate_doc=2&pos=1;-0.0999908447265625&pos2=3;-100.09999084472656

- SP RK EN 1993-4-3:2007/2011. Proektirovanie stal'nykh konstruktsiy. Ch. 4-3. Truboprovody. Available at: https://online.zakon.kz/Document/?doc_id=34586480

- EN 1998-4 (2006) (English): Eurocode 8: Design of structures for earthquake resistance – Part 4: Silos, tanks and pipelines. Available at: https://www.phd.eng.br/wp-content/uploads/2014/12/en.1998.4.2006.pdf

- EN 1993-1-8 (2005) (English): Eurocode 3: Design of steel structures - Part 1-8: Design of joints. Available at: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1993.1.8.2005-1.pdf

- Tekhnicheskie usloviya na truby dlya truboprovodov. API Spec. 5L. Available at: https://buy-pipe.com/home/structure/item_214/955b42b7590d39be6f4d268afcd0a015.pdf

- SP 284.1325800.2016. Truboprovody promyslovye dlya nefti i gaza. Pravila proektirovaniya i proizvodstvo rabot. Available at: https://files.stroyinf.ru/Data2/1/4293742/4293742910.pdf

- ASME 831G-1991. Manual for Determining the Remaining Strength of Corroded Pipelines. Available at: https://law.resource.org/pub/us/cfr/ibr/002/asme.b31g.1991.pdf

- ASME B31.8-2003. Gas Transmission and Distribution, Piping Systems. Available at: https://law.resource.org/pub/us/cfr/ibr/002/asme.b31.8.2003.pdf

- Derevianko, I., Uspensky, B., Avramov, K., Salenko, A., Maksymenko-Sheiko, K. (2022). Experimental and numerical analysis of mechanical characteristics of fused deposition processed honeycomb fabricated from PLA or ULTEM 9085. Journal of Sandwich Structures & Materials, 25 (2), 264–283. doi: https://doi.org/10.1177/10996362221137292

- Barbero, E. J. (2013). Finite Element Analysis of Composite Materials Using Ansys. CRC Press, 366. doi: https://doi.org/10.1201/b16295

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Arman Moldagaliyev, Nurlan Zhangabay, Ulanbator Suleimenov, Konstantin Avramov, Talzhan Raimberdiyev, Maryna Chernobryvko, Altynsary Umbitaliyev, Atogali Jumabayev, Shairbek Yeshimbetov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.