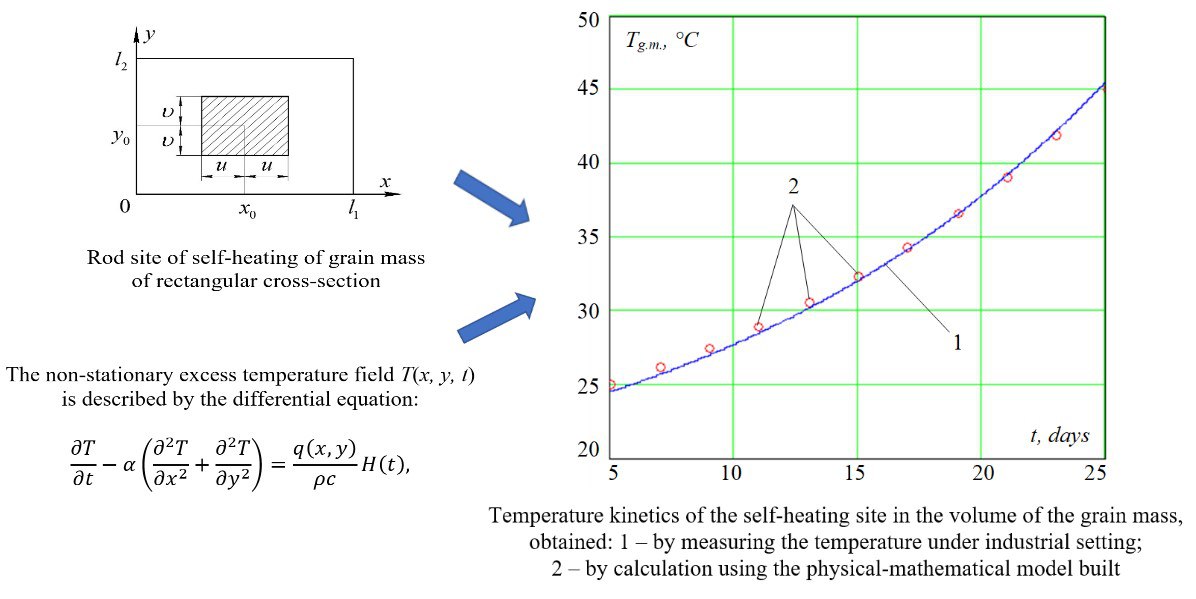

Constructing a physical-mathematical model of grain mass self-heating by a rod site of rectangular cross-section

DOI:

https://doi.org/10.15587/1729-4061.2023.287391Keywords:

self-heating of grain mass, temperature kinetics, model of a rod site of rectangular sectionAbstract

This paper considers the issue related to improving the energy and resource efficiency of the process of storing raw materials of plant origin, namely, preventing self-heating of grain masses in elevator silos. It was noted that the effectiveness of the analysis of self-heating of grain mass increases with the use of mathematical models of temperature fields of grain mass during storage together with data obtained experimentally. A physical-mathematical model has been built that describes a two-dimensional localized non-stationary temperature field of seed material generated by a homogeneous rod cell with a rectangular cross-section. A technique for accelerating the convergence of the series is proposed for the constructed analytical solution, which is based on the selection and analytical calculation of the sum of the component of slow convergence. The adequacy of the physical-mathematical model has been proven by calculations and by comparing the temperature of the self-heating site, obtained theoretically, and the temperature obtained under industrial setting. The established temperature kinetics of grain mass volumes during storage, obtained experimentally and theoretically, correlate with each other in the duration range from 0 to 30 days with a correlation coefficient of at least 0.98. This proves the possibility of applying forecasts of the temperature of self-heating sites in the volume of grain mass, obtained by using the physical-mathematical model built, under industrial setting. A limitation of the study is that the model is not universal. It is another stage on the way to a universal model. A limitation of the study is that for storage periods of more than 30 days, a new excess temperature forecast must be made

References

- Domaracka, L., Matuskova, S., Tausova, M., Senova, A., Kowal, B. (2022). Efficient Use of Critical Raw Materials for Optimal Resource Management in EU Countries. Sustainability, 14 (11), 6554. doi: https://doi.org/10.3390/su14116554

- Chen, G., Hou, J., Liu, C. (2022). A Scientometric Review of Grain Storage Technology in the Past 15 Years (2007–2022) Based on Knowledge Graph and Visualization. Foods, 11 (23), 3836. doi: https://doi.org/10.3390/foods11233836

- Olorunfemi, B. J., Kayode, S. E. (2021). Post-Harvest Loss and Grain Storage Technology- A Review. Turkish Journal of Agriculture - Food Science and Technology, 9 (1), 75–83. doi: https://doi.org/10.24925/turjaf.v9i1.75-83.3714

- Cui, H., Zhang, Q., Wu, W., Zhang, H., Ji, J., Ma, H. (2022). Modeling and Application of Temporal Correlation of Grain Temperature during Grain Storage. Agriculture, 12 (11), 1883. doi: https://doi.org/10.3390/agriculture12111883

- Wang, X., Wu, W., Yin, J., Zhang, Z., Wu, Z., Zhang, H. (2018). Analysis of wheat bulk mould and temperature-humidity coupling based on temperature and humidity field cloud map. Nongye Gongcheng Xuebao/Transactions of the Chinese Society of Agricultural Engineering, 34 (10), 260–266. doi: https://doi.org/10.11975/j.issn.1002-6819.2018.10.033

- Yan, H., Chen, G., Zhou, Y., Liu, L. (2012). Primary study of temperature distribution measurement in stored grain based on acoustic tomography. Experimental Thermal and Fluid Science, 42, 55–63. doi: https://doi.org/10.1016/j.expthermflusci.2012.04.010

- Ge, L Chen, E. (2021). Research on grain storage temperature prediction model based on improved long short-term memory. Journal of Computational Methods in Sciences and Engineering, 21 (5), 1145–1154. doi: https://doi.org/10.3233/jcm-204751

- Quemada-Villagómez, L. I., Molina-Herrera, F. I., Carrera-Rodríguez, M., Calderón-Ramírez, M., Martínez-González, G. M., Navarrete-Bolaños, J. L., Jiménez-Islas, H. (2020). Numerical Study to Predict Temperature and Moisture Profiles in Unventilated Grain Silos at Prolonged Time Periods. International Journal of Thermophysics, 41 (5). doi: https://doi.org/10.1007/s10765-020-02636-5

- Ol'shanskii, V. P. (2001). Temperature field of bedded self-heating of a bank in a silo. Combustion, Explosion and Shock Waves, 37, 53–56. doi: https://doi.org/10.1023/A:1002816725317

- Ol'shanskii, V. P. (2004). Identification of the Parameters of a Nested Cylindrical Heat Source under Stationary Self‐Heating of a Raw Material Mass of the Same Form. Journal of engineering physics and thermophysics, 77 (1), 242–246. doi: https://doi.org/10.1023/B:JOEP.0000020747.49072.8b

- Jayanti, S., Valette, M. (2005). Calculation of dry out and post-dry out heat transfer in rod bundles using a three field model. International Journal of Heat and Mass Transfer, 48 (9), 1825–1839. doi: https://doi.org/10.1016/j.ijheatmasstransfer.2004.11.005

- Ol'shanskii, V. P. (2002). Steady-state temperature field of a cylindrical mass of raw material when it is self-heated by an ellipsoidal source. Journal of Engineering Physics and Thermophysics, 75 (4), 954–956. doi: https://doi.org/10.1023/A:1020331622455

- Olshanskiy, V. P., Slipchenko, M. V., Olshanskiy, O. V. (2021). To calculation and forecast of the temperature of formation self-heating of plant raw materials. Engineering of nature management, 3 (21), 66–72. doi: https://doi.org/10.5281/zenodo.7316973

- Biliaiev, М. М., Berlov, O. V., Biliaieva, V. V., Kozachyna, V. A. (2022). Numerical simulation of the process of self-heating of plant raw materials for the purpose of determining the time of the fire initiation. Ukrainian Journal of Civil Engineering and Architecture, 6, 7–13. doi: https://doi.org/10.30838/j.bpsacea.2312.281221.7.809

- Subrot Panigrahi, S., Singh, C. B., Fielke, J., Zare, D. (2019). Modeling of heat and mass transfer within the grain storage ecosystem using numerical methods: A review. Drying Technology, 38 (13), 1677–1697. doi: https://doi.org/10.1080/07373937.2019.1656643

- Olshanskyi, В., Kharchenko, С., Slipchenko, М., Kovalyshyn, С., Mazurak, М. (2021). On calculation of the temperature of raw material self-heating in cylindrical tanks. Bulletin of Lviv National Environmental University. Agroengineering Research, 25, 21–27. doi: https://doi.org/10.31734/agroengineering2021.25.021

- Askarov, A., Tlevlessova, D., Ostrikov, A., Shambulov, Y., Kairbayeva, A. (2022). Developing a statistical model for the active ventilation of a grain layer with high moisture content. Eastern-European Journal of Enterprise Technologies, 1 (11 (115)), 6–14. doi: https://doi.org/10.15587/1729-4061.2022.253038

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Maksym Slipchenko, Vadym Bredykhin, Andrey Pak, Petro Gurskyi, Oleksiy Alfyorov, Alina Pak

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.