Determining the effect of the direction of installing the cutting edges of shredder roller blades on process parameters

DOI:

https://doi.org/10.15587/1729-4061.2023.287483Keywords:

shredder roller, cutting edge of a blade, analytical dependences of the planar motion of shredder roller, traction resistance of shredder rollerAbstract

This paper reports a study aimed at increasing the intensity of grinding of the stems of coarse-stemmed crops by establishing the influence of the orientation of the cutting edge of the cutter-shredder knives on the quality of the technological grinding operations.

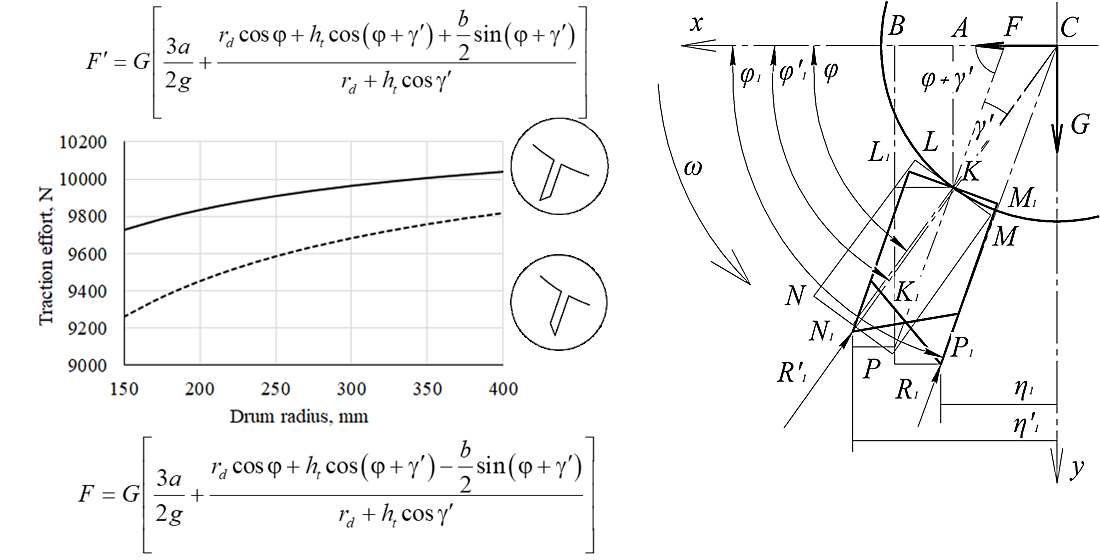

Analytical dependences of the planar movement of the roller-shredder were established and it was determined that for rollers with knives, the cutting edge of which is directed in the direction opposite to the direction of rotation:

– exceeding the value of the vertical components of the total forces of resistance of the knives, which made it possible to increase the values of forces, and, as a result, more intensive destruction of the layer of plant remains;

– exceeding the values of the driving force of the knives based on the dependence of the driving force on structural and kinematic parameters (roller weight, drum radius, blade height, blade inclination angle, acceleration).

Experimental studies have established an excess of up to 20 % of the quality indicators of milling sunflower and corn stems with roller knives, the cutting edge of which is directed in the direction opposite to the direction of rotation.

The average number of crushed pieces of corn stalks in the range of less than 50 mm is 13.6 % higher in the combined unit, the cutter blades of which are directed with the cutting edge in the direction opposite to the direction of rotation.

It was established that with zero and 3.92 kN (400 kg) additional loading, an increase in speed from 7.45 km/h to 13.6 km/h leads to a decrease in the values of the average traction resistance. The highest value of traction resistance was set at a speed of 13.6 km/h and an additional load of 7.84 kN (800 kg). The lowest value of traction resistance was established at zero additional load and a speed of 22.0 km/h, which is 21.5 % less than at a speed of 7.45 km/h and 14.1 % less than at a speed of 13.6 km/h.

References

- Jia, H., Ma, C., Liu, F., Liu, Z., Yu, H., Tan, H. (2005). Study on technology and matching machine for stalk/stubble breaking and mulching combined operation. NongyeJixieXuebao/Transactions of the Chinese Society of Agricultural Machinery, 36 (11), 46–49.

- Kukuruznyy motylek – znachenie, predupreditel'nye mery i strategii bor'by (2018). TerraHORCH, 16, 12–14. Available at: https://www.horsch.com/fileadmin/user_upload/downloads/ru-russisch/terraHORSCH/TH_16_2018_ru.pdf

- Na ostrie nozha: Cultro TC (2019). ТerraHORCH, 19, 8–9. Available at: https://www.horsch.com/fileadmin/user_upload/downloads/ru-russisch/terraHORSCH/TH_19_2019_RU.pdf

- Salo, V., Bohatyrov, D., Leshchenko, S., Savytskyi, M. (2014). Vitchyzniane tekhnichne zabezpechennia suchasnykh protsesiv u roslynnytstvi. Tekhnika i tekhnolohiyi APK, 10, 16–19. Available at: http://nbuv.gov.ua/UJRN/Titapk_2014_10_6

- Behera, A., Raheman, H., Thomas, E. V. (2021). A comparative study on tillage performance of rota-cultivator (a passive – active combination tillage implement) with rotavator (an active tillage implement). Soil and Tillage Research, 207, 104861. doi: https://doi.org/10.1016/j.still.2020.104861

- Gürsoy, S., Kolay, B., Avşar, Ö., Sessiz, A. (2015). Evaluation of wheat stubble management practices in terms of the fuel consumption and field capacity. Research in Agricultural Engineering, 61 (3), 116–121. doi: https://doi.org/10.17221/77/2013-rae

- Dongxu, L., Yiyuan, G., Chuanhua, Y., Junfa, W., Chao, C. (2022). Simulation and experimental of scimitar-straw-soil interaction model based on discrete element method. Journal of Chinese Agricultural Mechanization, 43 (4), 1–6. doi: https://doi.org/10.13733/j.jcam.issn.2095-5553.2022.04.001

- Wang, Q., Liu, Z., He, J., Li, H., Li, W., He, J., Yan, X. (2018). Design and experiment of chopping-type maize straw returning machine. Nongye Gongcheng Xuebao/Transactions of the Chinese Society of Agricultural Engineering, 34 (2), 10–17. doi: https://doi.org/10.11975/j.issn.1002-6819.2018.02.002

- Miszczak, M. (2005). A torque evaluation for a rotary subsoiler. Soil and Tillage Research, 84 (2), 175–183. doi: https://doi.org/10.1016/j.still.2004.11.011

- Wang, R., Yang, P., Jahun, R. F., Dou, S. (2017). Design and experiment of combine machine for deep furrowing, stubble chopping, returning and burying of chopped straw. Nongye Gongcheng Xuebao/Transactions of the Chinese Society of Agricultural Engineering, 33 (5), 40–47. doi: http://dx.doi.org/10.11975/j.issn.1002-6819.2017.05.006

- Sheichenko, V., Volskyi, V., Kotsiubanskyi, R., Dnes, V., Shevchuk, M., Bilovod, O., Drozhchana, O. (2021). Design of a roll crusher for sunflower stems and substantiation of the rational modes of its operation. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 28–37. doi: https://doi.org/10.15587/1729-4061.2021.244903

- Sheichenko, V., Volskyi, V., Kotsiubanskyi, R., Skoriak, Y., Priliepo, N. (2022). Analysis of the operation of the blades of the skating rink – chopper in the conditions of its rolling on the ground. Scientific Progress & Innovations, 2 (2), 296–306. doi: https://doi.org/10.31210/visnyk2022.02.35

- Sheichenko, V., Volskyi, V., Kotsiubanskyi, R., Dnes, V. (2022). Study of grinding corn stalks by a roller grinder with different knives positioning. Mechanization in agriculture & Conserving of the resources, 66 (2), 71–74. Available at: https://stumejournals.com/journals/am/2022/2/71

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Victor Sheichenko, Volodymyr Volskyi, Rostyslav Kotsiubanskyi, Viktor Dnes, Oleksandra Bilovod, Misha Shevchuk, Yuliia Skoriak

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.