Detecting the influence of uneven loading of the brake shoe in a freight car bogie on its strength

DOI:

https://doi.org/10.15587/1729-4061.2023.287791Keywords:

freight car, brake shoe of a car, stressed state of the shoe, transport mechanics, traffic safetyAbstract

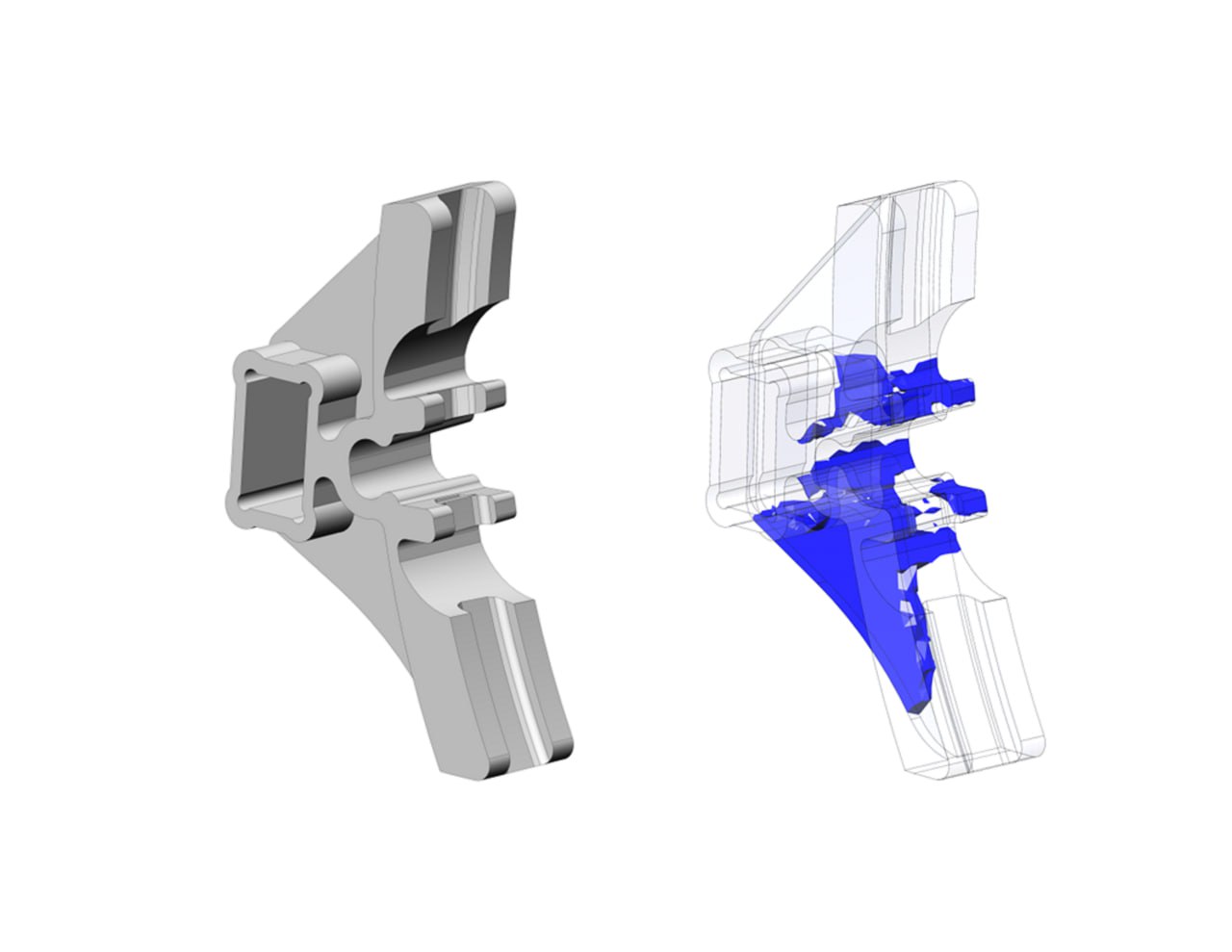

The object of the study is the processes of occurrence, perception, and redistribution of loads in the brake shoe of a freight car bogie during braking. In order to ensure the safety of the movement of freight cars, a study of the uneven load on the bogie shoe of the model 18-100 freight car was carried out. A mathematical apparatus was built to determine the strength of the brake shoe, taking into account the uneven load transmitted to it from the brake pad. In this case, the brake shoe was considered in the form of a frame with variable stiffness. It was established that the stresses that occur in the shoe exceed the permissible ones. To test the proposed mathematical apparatus, a computer simulation of the strength of the brake shoe was carried out. In this case, the finite element method, which is implemented in SolidWorks Simulation, was used. The difference between the results obtained by mathematical modeling and computer simulation was 5.7 %.

A feature of the research results is that they make it possible to determine the moment of resistance, and accordingly, the stresses that act in the shoe along its length. This will make it possible to design its fundamentally new structure at the subsequent stages.

The field of practical application of the reported results is the engineering industry, in particular, railroad transport. The conditions for the practical application of the research results are to ensure the strength of the shoe during braking of the rolling stock in operation.

The study will contribute to advancements in improving the reliability of the braking systems of bogies, as well as ensuring the manufacturability and maintainability in the construction, operation, and repair of the components of the mechanical part of brakes for the new generation freight cars

References

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Pavliuchenkov, M., Kravchenko, K. (2022). The Analysis of the Loading and the Strength of the FLAT RACK Removable Module with Viscoelastic Bonds in the Fittings. Applied Sciences, 13 (1), 79. doi: https://doi.org/10.3390/app13010079

- Dižo, J., Harušinec, J., Blatnický, M. (2017). Structural Analysis of a Modified Freight Wagon Bogie Frame. MATEC Web of Conferences, 134, 00010. doi: https://doi.org/10.1051/matecconf/201713400010

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Rybin, A., Kravchenko, O. (2023). Strength Assessment of an Improved Design of a Tank Container under Operating Conditions. Communications - Scientific Letters of the University of Zilina, 25 (3). doi: https://doi.org/10.26552/com.c.2023.047

- Koptovets, O., Haddad, J. S., Brovko, D., Posunko, L., Tykhonenko, V. (2020). Identification of the conditions of a mine locomotive brake system as well as its functional and morphological model with the stressed closed kinematic circuit. E3S Web of Conferences, 201, 01033. doi: https://doi.org/10.1051/e3sconf/202020101033

- Gupta, V., Saini, K., Garg, A. K., Krishan, G., Parkash, O. (2016). Comparative Analysis of Disc Brake Model for Different Materials Investigated Under Tragic Situations. Asian Review of Mechanical Engineering, 5 (1), 18–23. doi: https://doi.org/10.51983/arme-2016.5.1.2409

- Safronov, O. (2018). Application of computer-aided simulation to obtain a more precise estimation of brake efficiency of freigh wagons. Collection of Scientific Works of the State University of Infrastructure and Technologies Series “Transport Systems and Technologies,” 32 (2), 61–75. doi: https://doi.org/10.32703/2617-9040-2018-32-2-61-75

- Voloshin, D., Afanasenko, I., Derevianchuk, Ya. (2018). The question of the hopper-сar mechanical brake elements improving. Visnyk Skhidnoukrainskoho natsionalnoho universytetu imeni Volodymyra Dalia, 2 (243), 54–59. Available at: https://journals.indexcopernicus.com/api/file/viewByFileId/474997.pdf

- Cruceanu, C., Oprea, R., Spiroiu, M., Craciun, C., Arsene, S. (2009). Computer Aided Study Regarding the Influence of Filling Characteristics on the Longitudinal Reactions within the Body of a Braked Train. 13th WSEAS International Conference on Computers, 531–536. Available at: https://www.researchgate.net/publication/239527005_Computer_Aided_Study_Regarding_the_Influence_of_Filling_Characteristics_on_the_Longitudinal_Reactions_within_the_Body_of_a_Braked_Train

- Cruceanu, C. (2012). Train Braking. Reliability and Safety in Railway. doi: https://doi.org/10.5772/37552

- Kiss, I. (2016). The chemical composition of phosphorous cast irons behavior in the manufacturing of brake shoes meant for the rolling stock. Acta Technica Corviniensis - Bulletin of Engineering, 9 (3), 77–84. Available at: https://www.proquest.com/docview/1806389126

- Panchenko, S., Vatulia, G., Lovska, A., Ravlyuk, V., Elyazov, I., Huseynov, I. (2022). Influence of structural solutions of an improved brake cylinder of a freight car of railway transport on its load in operation. EUREKA: Physics and Engineering, 6, 45–55. doi: https://doi.org/10.21303/2461-4262.2022.002638

- Cruceanu, C. (2007). Brakes for railway vehicles. Bucharest: Matrix Rom.

- Pascu, L. V. (2015). Cercetări privind îmbunătăţirea calităţii saboţilor de frână destinaţi materialului rulant. University Politehnica Timisoara.

- Kiss, I., Cioata, V., Alexa, V., Ratiu, R. (2016). Investigations on the selection of friction materials destined to railway vehicles applications. Annals of the Faculty of Engineering Hunedoara, 14 (4). Available at: https://annals.fih.upt.ro/pdf-full/2016/ANNALS-2016-4-37.pdf

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Ravlyuk, V., Harusinec, J. (2023). Studying the load of composite brake pads under high-temperature impact from the rolling surface of wheels. EUREKA: Physics and Engineering, 4, 155–167. doi: https://doi.org/10.21303/2461-4262.2023.002994

- Ravlyuk, V., Elyazov, İ., Afanasenko, I., Ravliuk, M. (2020). Determination of parameters of abnormal wear of brake pads of freight cars. E3S Web of Conferences, 166, 07003. doi: https://doi.org/10.1051/e3sconf/202016607003

- Chykhladze, E. D. (2011). Opir materialiv. Kharkiv: UkrDAZT, 366. Available at: https://btpm.nmu.org.ua/ua/download/navch-posib/Чихладзе.ОМ.Підручник.pdf

- Vatulia, H. L., Hlazunov, Yu. V., Kravtsiv, L. B., Smolianiuk, N. V. (2016). Rozrakhunok rozpirnykh system. Kharkiv: UkrDUZT, 124.

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252. Available at: https://ep3.nuwm.edu.ua/22175/1/Комп%27ютерна%20графіка.pdf

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172. Available at: https://lib.lntu.edu.ua/sites/default/files/2021-02/Інженерна%20графіка%20в%20SolidWorks.pdf

- Lovskaya, A. (2014). Assessment of dynamic efforts to bodies of wagons at transportation with railway ferries. Eastern-European Journal of Enterprise Technologies, 3 (4 (69)), 36–41. doi: https://doi.org/10.15587/1729-4061.2014.24997

- Lovskaya, A., Ryibin, A. (2016). The study of dynamic load on a wagon–platform at a shunting collision. Eastern-European Journal of Enterprise Technologies, 3 (7(81)), 4–8. doi: https://doi.org/10.15587/1729-4061.2016.72054

- Kondratiev, A. V., Gaidachuk, V. E. (2021). Mathematical Analysis of Technological Parameters for Producing Superfine Prepregs by Flattening Carbon Fibers. Mechanics of Composite Materials, 57 (1), 91–100. doi: https://doi.org/10.1007/s11029-021-09936-3

- Stoilov, V., Simić, G., Purgić, S., Milković, D., Slavchev, S., Radulović, S., Maznichki, V. (2019). Comparative analysis of the results of theoretical and experimental studies of freight wagon Sdggmrss-twin. IOP Conference Series: Materials Science and Engineering, 664 (1), 012026. doi: https://doi.org/10.1088/1757-899x/664/1/012026

- Das, A., Agarwal, G. (2020). Investigation of Torsional Stability and Camber Test on a Meter Gauge Flat Wagon. Advances in Fluid Mechanics and Solid Mechanics, 271–280. doi: https://doi.org/10.1007/978-981-15-0772-4_24

- Dižo, J., Blatnický, M., Sága, M., Harušinec, J., Gerlici, J., Legutko, S. (2020). Development of a New System for Attaching the Wheels of the Front Axle in the Cross-Country Vehicle. Symmetry, 12 (7), 1156. doi: https://doi.org/10.3390/sym12071156

- Fomin, O., Lovska, A. (2021). Determination of dynamic loading of bearing structures of freight wagons with actual dimensions. Eastern-European Journal of Enterprise Technologies, 2 (7 (110)), 6–14. doi: https://doi.org/10.15587/1729-4061.2021.220534

- Lovska, A., Fomin, O., Píštěk, V., Kučera, P. (2020). Dynamic Load and Strength Determination of Carrying Structure of Wagons Transported by Ferries. Journal of Marine Science and Engineering, 8 (11), 902. doi: https://doi.org/10.3390/jmse8110902

- Šťastniak, P., Moravčík, M., Smetanka, L. (2019). Investigation of strength conditions of the new wagon prototype type Zans. MATEC Web of Conferences, 254, 02037. doi: https://doi.org/10.1051/matecconf/201925402037

- Lee, W. G., Kim, J.-S., Sun, S.-J., Lim, J.-Y. (2016). The next generation material for lightweight railway car body structures: Magnesium alloys. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232 (1), 25–42. doi: https://doi.org/10.1177/0954409716646140

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. doi: https://doi.org/10.1177/0954409715593971

- Wennberg, D., Stichel, S., Wennhage, P. (2012). Substitution of corrugated sheets in a railway vehicle’s body structure by a multiple-requirement based selection process. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 228 (2), 143–157. doi: https://doi.org/10.1177/0954409712467139

- Harak, S. S., Sharma, S. C., Harsha, S. P. (2014). Structural Dynamic Analysis of Freight Railway Wagon Using Finite Element Method. Procedia Materials Science, 6, 1891–1898. doi: https://doi.org/10.1016/j.mspro.2014.07.221

- Molavitabrizi, D., Laliberte, J. (2020). Methodology for multiscale design and optimization of lattice core sandwich structures for lightweight hopper railcars. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234 (21), 4224–4238. doi: https://doi.org/10.1177/0954406220920694

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sergii Panchenko, Alyona Lovska, Vasyl Ravlyuk, Andrii Babenko, Oleksandr Derevyanchuk, Oksana Zharovа, Yaroslav Derevianchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.