Developing the optimal chemical composition of heat-resistant Cr-Ni steel for aerospace equipment

DOI:

https://doi.org/10.15587/1729-4061.2023.288224Keywords:

austenitic heat-resistant chrome-nickel steel, alloying elements, microstructure, carbides, mechanical properties, regression analysisAbstract

The object of research in this work is the processes of forming the microstructure and mechanical properties of heat-resistant steels depending on their chemical composition.

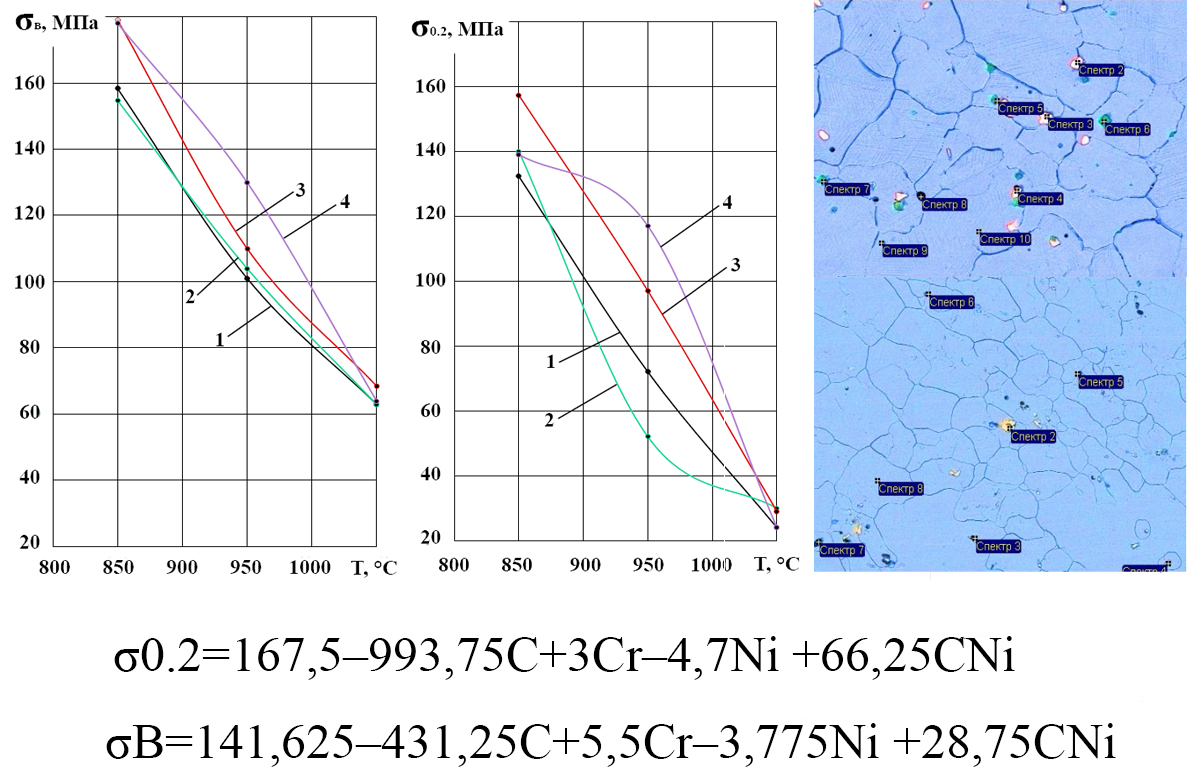

The microstructure and high-temperature mechanical properties of austenitic heat-resistant chrome-nickel steels of the proposed chemical composition were investigated in the work. The microstructure study determined the grain size and topography of inclusions in steels. Based on the results of mechanical tests, a multifactorial experiment was planned, which made it possible to establish the relationship between the mechanical properties of steels with alloying elements selected as factors. The obtained regression equations were used to estimate the quantitative influence of each alloying element on the corresponding mechanical properties.

Analysis of the results of the experiment made it possible to determine the optimal chemical composition of steel for gas turbine engines used in the aerospace industry, as well as in the metallurgy of titanium production.

It is shown that the state of solid solution and heat-resistant niobium and molybdenum carbides (chromium carbides dissolve at a temperature of 950 °C) are an important factor that significantly affects the structure, mechanical, and service properties of heat-resistant steel. The austenite structure is provided by the required amount of nickel.

The resulting indicators of heat resistance of steels of different compositions, tested at temperatures of 850 °C, 950 °C, and 1050 °C, proved the superiority of steel with a higher content of carbon and chromium and a lower content of nickel.

The mechanism of steel strengthening and the influence of alloying with carbon, chromium, and nickel on it have been determined. The optimal chemical composition of heat-resistant steel on an iron-nickel basis for operation at a temperature of 950 °C has been established

References

- Collins, D. A., Carter, E. L., Lach, T. G., Byun, T. S. (2022). A comprehensive study of the effects of long-term thermal aging on the fracture resistance of cast austenitic stainless steels. Nuclear Engineering and Technology, 54 (2), 709–731. doi: https://doi.org/10.1016/j.net.2021.08.022

- Roussel, M., Sauvage, X., Perez, M., Magné, D., Hauet, A., Steckmeyer, A. et al. (2018). Influence of solidification induced composition gradients on carbide precipitation in FeNiCr heat resistant steels. Materialia, 4, 331–339. doi: https://doi.org/10.1016/j.mtla.2018.10.010

- Zhou, Y., Liu, Y., Zhou, X., Liu, C., Yu, J., Huang, Y. et al. (2017). Precipitation and hot deformation behavior of austenitic heat-resistant steels: A review. Journal of Materials Science & Technology, 33 (12), 1448–1456. doi: https://doi.org/10.1016/j.jmst.2017.01.025

- Ligabo, I. A., Braga, V., Ferreira, C. C. A., Siqueira, R. H. M., Lourenço, J. C., Abdalla, A. J., Lima, M. S. F. (2022). Microstructure and Corrosion Behavior of AISI 316 Steel Layers Deposited on AISI 347 Steel Substrate by Laser Metal Deposition. Metals, 12 (12), 2161. doi: https://doi.org/10.3390/met12122161

- Shelyagin, V. D., Bernatskyi, A. V., Siora, O. V., Kurilo, V. A., Suchek, O. M. (2020). Development of remotely-controlled equipment and technology for laser welding and restoration of performance of NPS steam generators. Automatic Welding, 2020 (12), 30–36. doi: https://doi.org/10.37434/as2020.12.04

- Nesterenko, S. (2020). Corrosion resistance of new austenitic-ferritic steels in aggressive environments by-product coke plants. XV Mizhnarodna konferentsiya "Problemy korozii ta protykoroziinoho zakhystu konstruktsiynykh materialiv". Lviv, 337–341. Available at: https://www.ipm.lviv.ua/corrosion2020/Chapter_05/XII_337_%20NESTERENKO.pdf

- Mishchenko, V., Byelikov, S., Klimov, O., Kripak, А., Tonkonoh, D., Kornienko, V., Kharchenko, А. (2023). Creation of special construction material using the rolling method of asymmetrical packages for dual-purpose products. New Materials and Technologies in Metallurgy and Mechanical Engineering, 2, 32–37. doi: https://doi.org/10.15588/1607-6885-2023-2-5

- Mishchenko, V., Loskutov, S., Kripak, A. (2022). Determining the thermoplastic deformation mechanism of titanium reduction reactors and recommendations to increase the reactor service life. Eastern-European Journal of Enterprise Technologies, 5 (7 (119)), 14–20. doi: https://doi.org/10.15587/1729-4061.2022.265577

- Novik, F. S., Arsov, YA. B. (1980). Optimizatsiya protsessov tekhnologii metallov metodami planirovaniya eksperimentov. Moscow: Mashinostroenie; Sofiya: Tekhnika, 304.

- Adler, Yu. P., Markova, E. V., Granovskiy, Yu. V. (1976). Planirovanie eksperimenta pri poiske optimal'nykh usloviy. Moscow: Nauka, 280.

- Sroka, M., Zieliński, A., Golański, G., Kremzer, M. (2019). The Influence of Long-term Ageing on the Microstructure of Sanicro 25 Steel. MATEC Web of Conferences, 253, 03004. doi: https://doi.org/10.1051/matecconf/201925303004

- Zhou, Q., Ping, S., Meng, X., Wang, R., Gao, Y. (2017). Precipitation Kinetics of M23C6 Carbides in the Super304H Austenitic Heat-Resistant Steel. Journal of Materials Engineering and Performance, 26 (12), 6130–6139. doi: https://doi.org/10.1007/s11665-017-2982-2

- Dhivyasri, G., Sudha, R. (2018). Optimization of AISI 316 materials mechanical properties for CMT application. International Journal of Mechanical Engineering and Technology (IJMET), 9 (11), 1269–1279. Available at: https://iaeme.com/MasterAdmin/Journal_uploads/IJMET/VOLUME_9_ISSUE_11/IJMET_09_11_131.pdf

- Desu, R. K., Nitin Krishnamurthy, H., Balu, A., Gupta, A. K., Singh, S. K. (2016). Mechanical properties of Austenitic Stainless Steel 304L and 316L at elevated temperatures. Journal of Materials Research and Technology, 5 (1), 13–20. doi: https://doi.org/10.1016/j.jmrt.2015.04.001

- Mishchenko, V. (2003). Metallurgical aspects of the production of chromium-nickel steels with low carbon contents. Foundary Jornal of Polish Foundrymen`s Technicsl Association, 3, 326–329.

- Gayduk, S, Kononov, V. (2017). Structural stability parameters forecast for high-temperature nickel-base cast alloys. Herald of Aeroenginebuilding, 1, 139–148. Available at: http://vd.zntu.edu.ua/article/view/114102

- Wärner, H., Calmunger, M., Chai, G., Johansson, S., Moverare, J. (2019). Thermomechanical fatigue behaviour of aged heat resistant austenitic alloys. International Journal of Fatigue, 127, 509–521. doi: https://doi.org/10.1016/j.ijfatigue.2019.06.012

- Drápala, J., Kostiuková, G., Losertová, M. (2018). Influence of heat treatment on microstructure and mechanical properties of SUS 316L alloy. METAL 2018 - 27th International Conference on Metallurgy and Materials. Brno, 1527–1532. Available at: https://www.confer.cz/metal/2018/read/1305-influence-of-heat-treatment-on-microstructure-and-mechanical-properties-of-sus-316l-alloy.pdf

- Zhou, Y., Li, Y., Liu, Y., Guo, Q., Liu, C., Yu, L. et al. (2015). Precipitation behavior of type 347H heat-resistant austenitic steel during long-term high-temperature aging. Journal of Materials Research, 30 (23), 3642–3652. doi: https://doi.org/10.1557/jmr.2015.343

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Valeriy Mishchenko, Alona Kripak, Dmytro Tonkonoh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.