Efficiency of gas preparation technology using a block drying plant

DOI:

https://doi.org/10.15587/1729-4061.2023.288225Keywords:

freon refrigeration plant, gas drying, separation, payback period, gas distribution systemAbstract

The object of research is the technology of gas drying using a mobile block installation. The task to ensure compliance of the composition of natural gas with the values of a number of basic characteristics before its supply to main pipelines has been solved. The results of a complex analysis of the gas preparation technology of the deposit, which is located in an agricultural area and is at a late stage of exploitation, are reported. It was established that in order to ensure the supply of conditioned gas to the system of main gas pipelines under the conditions of low gas pressures, the construction of gas treatment plants is required, first of all, for its drying.

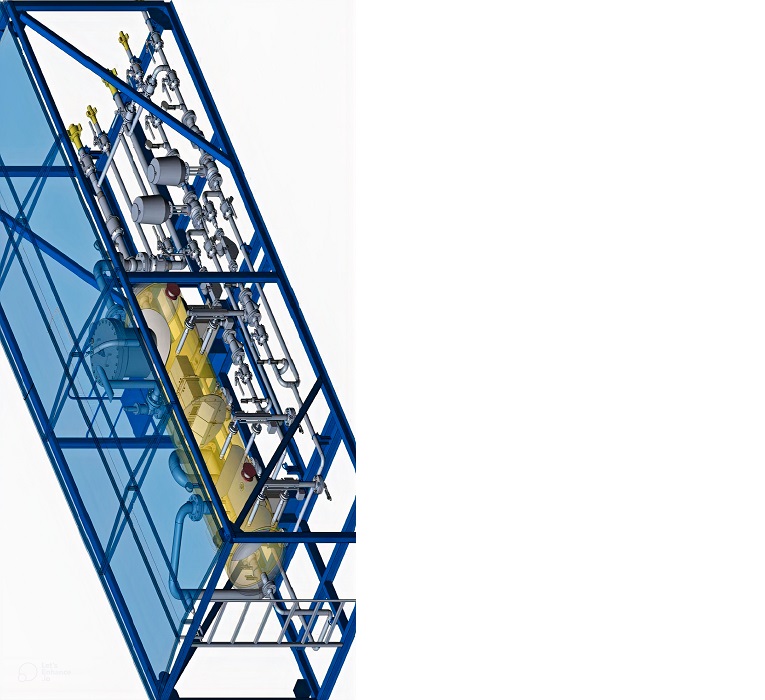

The method of ensuring gas quality considered in the current paper involves the use of a block-type gas drying installation as part of a low-temperature separation installation and a source of artificial cold. As the latter, it is envisaged to use a freon-refrigerating unit. The study shows that the proposed block gas drying units can be unified for different gas productivity and are characterized by relatively low capital and operating costs. The main advantages of the introduction of gas preparation block installations and the scheme of connecting the installation to the existing line are presented.

Based on the results of the economic efficiency indicators, it was established that the use of a block gas drying unit is a profitable project with the value of the accumulated reduced free cash flow of almost 843 thousand conditional units; the investment payback period is 3 years. The results could be effectively used in the gas distribution sector, provided that the gas is extracted from a field close to exhaustion, which is characterized by low reservoir pressures

References

- Biletskyi, V. S., Orlovskyi, V. M., Vitryk, V. H. (2018). Osnovy naftohazovoi inzheneriyi. Poltava: ASMI, 415. Available at: https://repository.kpi.kharkov.ua/items/7178193a-9948-4638-924f-657cbb91366c

- Mykhailov, V. A., Vakarchuk, S. H., Zeikan, O. Yu., Kasianchuk, S. V., Kurovets, I. M., Vyzhva, S. A. et al. (2014). Netradytsiyni dzherela vuhlevodniv Ukrainy. Kyiv: Nika-Tsentr, 280. Available at: http://elar.nung.edu.ua/handle/123456789/5162

- Agarwal, P., Patel, P., Jain, S. (2013). Installation of Unique & First of Its kind, Gas Enrichment Plant - Natural Gas Purification and Drying Unit to Remove the Excessive Quantity of Nitrogen, Carbon Dioxide & Helium from the Natural Gas Produced at the Marginal Gas Fields of Rajasthan, India. Proceedings of SPE Asia Pacific Oil & Gas Conference and Exhibition. doi: https://doi.org/10.2118/165741-ms

- Jin, L., Hawthorne, S., Sorensen, J., Pekot, L., Bosshart, N., Gorecki, C. et al. (2017). Utilization of Produced Gas for Improved Oil Recovery and Reduced Emissions from the Bakken Formation. SPE Health, Safety, Security, Environment, & Social Responsibility Conference. doi: https://doi.org/10.2118/184414-ms

- Kravchenko, S., Popov, S., Gnitko, S. (2016). The working pressure research of piston pump RN-3.8. Eastern-European Journal of Enterprise Technologies, 5(1 (83)), 15–20. doi: https://doi.org/10.15587/1729-4061.2016.80626

- Sivanandam, S., Al Ali, M. (2020). Capturing in Gas Treating Plants Technology Review and Selection. Abu Dhabi International Petroleum Exhibition & Conference. doi: https://doi.org/10.2118/203479-ms

- Saha, C. K., Sabbir, A. S. M. Y. B., Sarker, S., Alam, Md. M. (2020). Development and Evaluation of LPG Based Heating System for BAU-STR Dryer. 2020 ASABE Annual International Virtual Meeting. doi: https://doi.org/10.13031/aim.202000780

- Orymbetov, E., Orymbetova, G. E., Khussanov, A. E., Orymbetov, T. E., Orymbetov, B. E. (2022). Sectioning of petroleum gas adsorption drying. Series of geology and technical sciences, 3 (453), 155–165. doi: https://doi.org/10.32014/2022.2518-170x.187

- Laing, W. (2003). Rising to the rural challenges. Petroleum review (London. 1968). MAR, 26–28.

- Liashenko, A., Makarenko, V., Vynnykov, Y., Petrash, O. (2021). Oil wells hydrate formation regularities. Eastern-European Journal of Enterprise Technologies, 3 (6 (111)), 19–24. doi: https://doi.org/10.15587/1729-4061.2021.233511

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleksandr Petrash, Stanislav Popov, Ruslan Petrash, Yuliia Levchenko, Anton Kelemesh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.