Determining the pattern of direction and distribution of intermetallic phase in the eutectic of the weld material after electron-beam welding of titanium and niobium alloys

DOI:

https://doi.org/10.15587/1729-4061.2023.288450Keywords:

electron beam welding, microcomposite alloy, eutectic decay, fiber size, weldAbstract

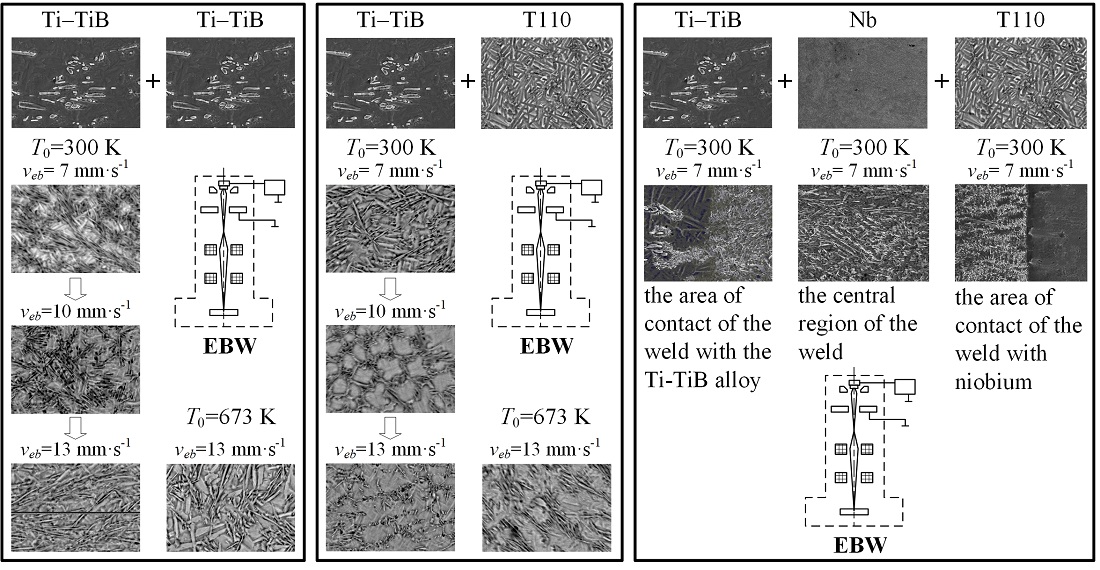

This paper reports a study whose object was material of the weld. The nature of changes in the microstructure of the weld material, which are caused by changes in the supplied energy, alloying elements and heat removal from the melt area, was investigated. Welding was performed with an electron beam at Uacc=60 kV, Ieb=90 mA, with an elliptical sweep of 3×4 mm. The speed of electron beam movement veb was varied from 7 to 15 mm·s-1. The temperature of the experimental welded samples T0 was varied from 300 K to 673 K. Ti-TiB alloy (a microcomposite alloy with reinforcing TiB fibers) was welded with Ti-TiB alloys, T110, and with niobium. One of the tasks of welding this alloy was to preserve and optimize the structure of this type in the weld. Grinding of boride fibers, loss of their initial orientation, and formation of a dendritic or cellular microstructure was observed in the weld.

Using the methods of raster electron microscopy and micro-X-ray spectral analysis, the microstructure of the weld material was investigated and the dimensional characteristics of TiB fibers under different welding conditions were determined. The analysis of changes in the microstructure of the weld material, the average length ᶏ and the thickness ȩ of the boride fibers in the material of the joints made at different velocities of electron beam movement and initial temperatures T0 was carried out. It was established that the growth of the ratio ȩ/ᶏ from 0.04–0.07 to 0.1–0.27 is accompanied by significant changes in the microstructure and the mechanism of formation of eutectic phases.

It is shown that the process that determines the formation of the microstructure of the weld material was the eutectic breakdown with the determining influence of the temperature gradient, crystallization rate, supercooling, concentration inhomogeneities, and alloying impurities.

References

- Tikhonovskiy, M. A. (2004). Issledovanie napravlennykh fazovykh prevrascheniy i razrabotka mikrokompozitnykh materialov v NNTs KhFTI. Voprosy atomnoy nauki i tekhniki, 6, 115–127. Available at: https://vant.kipt.kharkov.ua/ARTICLE/VANT_2004_6/article_2004_6_115.pdf

- Qi, J., Cheung, A. M., Poon, S. J. (2019). High Entropy Alloys Mined From Binary Phase Diagrams. Scientific Reports, 9 (1). doi: https://doi.org/10.1038/s41598-019-50015-4

- Andrievskaya, N. F., Kapcherin, A. S., Tikhonovskiy, M. A. (1980). Morfologicheskie perekhody v evtekticheskikh kompozitakh. Fizika prochnosti kompozitsionnykh materialov. Leningrad: Izd-vo LFTI, 42–44.

- Gaisin, R. A., Imayev, V. M., Imayev, R. M. (2017). Effect of hot forging on microstructure and mechanical properties of near α titanium alloy/TiB composites produced by casting. Journal of Alloys and Compounds, 723, 385–394. doi: https://doi.org/10.1016/j.jallcom.2017.06.287

- Grigorenko, G. M., Akhonin, S. V., Loboda, P. I., Grigorenko, S. G., Severin, A. Yu., Berezos, V. A., Bogomol, Yu. I. (2016). Structure And Properties Of Titanium Alloy, Alloyed With Boron, Produced By The Method Of Electron Beam Remelting. Electrometallurgy Today, 1, 21–25. doi: https://doi.org/10.15407/sem2016.01.03

- Gaisin, R. A., Imayev, V. M., Imayev, R. M. (2018). Microstructure and Mechanical Properties of a Near-α-Titanium-Alloy/TiB Composite Prepared in situ by Casting and Subjected to Deformation and Heat Treatment. Physics of Metals and Metallography, 119 (9), 907–916. doi: https://doi.org/10.1134/s0031918x18090041

- Bondarenko, Yu. A., Kablov, E. N. (2002). Napravlennaya kristallizatsiya zharoprochnykh splavov s povyshennym temperaturnym gradientom. Metallovedenie i termicheskaya obrabotka metallov, 7, 20–23.

- Kablov, E. N., Lukin, V. N. (2008). Intermetallidy na osnove titana i nikelya dlya izdeliy novoy tekhniki. Avtomaticheskaya svarka, 11, 76–82. Available at: http://dspace.nbuv.gov.ua/bitstream/handle/123456789/100041/09-Kablov.pdf?sequence=1

- Bagdasarov, Kh. S. (2004). Vysokotemperaturnaya kristallizatsiya iz rasplava. Moscow: FIZMATLIT, 160. Available at: https://www.studentlibrary.ru/book/ISBN5922104829.html

- Alikhanov, V., Khudoyan, M. V. (2019). Directionally crystallized eutectics obtaining method. University News. North-Caucasian Region. Technical Sciences Series, 1, 77–81. doi: https://doi.org/10.17213/0321-2653-2019-1-77-81

- Loboda, P., Zvorykin, C., Zvorykin, V., Vrzhyzhevskyi, E., Taranova, T., Kostin, V. (2020). Production and Properties of Electron-Beam-Welded Joints on Ti-TiB Titanium Alloys. Metals, 10 (4), 522. doi: https://doi.org/10.3390/met10040522

- Loboda, P., Zvorykin, V., Zvorykin, C., Vrzhyzhevskyi, E., Taranova, T., Kostin, V., Zvorykin, L. (2023). Features of the welded seam material crystallization in Ti-TiB alloy under electron-beam welding conditions. Mechanics and Advanced Technologies, 7 (1), 36–42. doi: https://doi.org/10.20535/2521-1943.2023.7.1.277544

- Loboda, P., Zvorykin, C., Zvorykin, V., Vrzhyzhevskyi, E., Taranova, T., Kostin, V. (2020). Structural regularities of welded seam between Ti-TiB and vanadium with 12X18H10T interlayer by using electron beam welding. Mechanics and Advanced Technologies, 2 (89). doi: https://doi.org/10.20535/2521-1943.2020.89.211400

- Hu, Z.-Y., Peng, H.-C., Zhang, Z.-H., Song, P., Chen, M., Ding, Y.-S. et al. (2021). Influence of the sintering temperature on the microstructure, mechanical properties and densification characteristics of (TiB + TiC)/TC4 composite. Materials Research Express, 8 (12), 126517. doi: https://doi.org/10.1088/2053-1591/ac40b7

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Petro Loboda, Anastasiia Zvorykina, Eduard Vrzhyzhevskyi, Tatjana Taranova, Valery Kostin, Volodymyr Zvorykin, Leonid Zvorykin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.