Optimizing the technological modes of lamination of digital prints

DOI:

https://doi.org/10.15587/1729-4061.2023.288518Keywords:

digital printing, prints, lamination modes, densitometric indicators, optimization of quality of laminatesAbstract

The intensive use of lamination technology for the decoration of printing prints made by various printing techniques, as well as a wide range of films, require solving an urgent problem – optimization of influencing factors to ensure the quality of laminated products. The objects of research were prints of inkjet and laser printing on paper, photo paper, and cardboard. A glossy film based on bio-oriented polypropylene BOPP was used for lamination. Studies of densitometric indicators of prints after lamination confirmed an increase in optical density by 0.28 units. This is especially true for inkjet prints. However, after lamination, all digital prints showed a tendency to improve colorimetric characteristics, namely an increase in the brightness of CMYK colors.

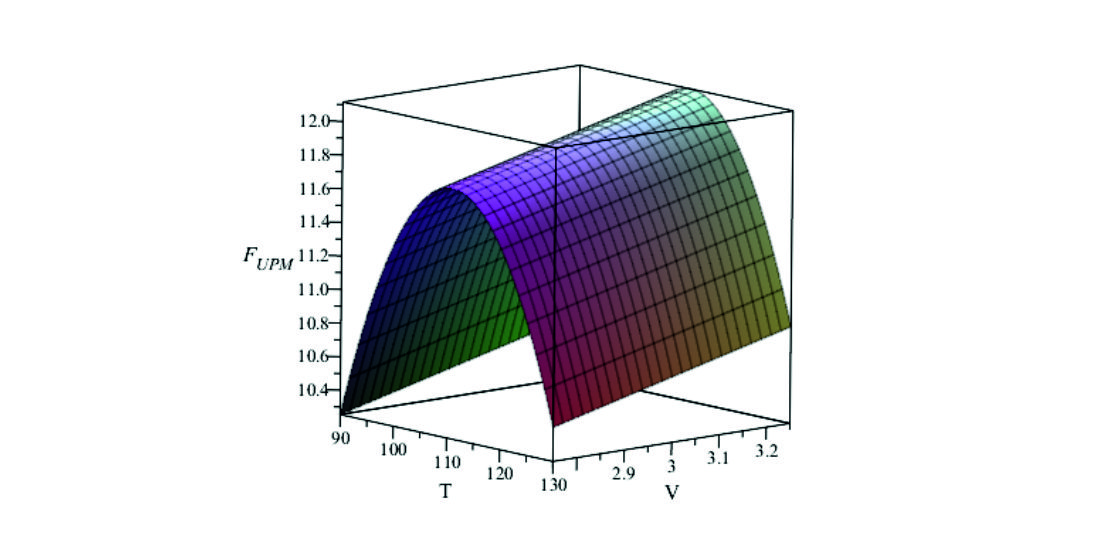

The relationship between the technological regimes of lamination (speed and temperature) and the strength of the laminates, estimated by breaking and pressing forces, was established. To describe the dependence of the laminate strength on the temperature and speed of lamination, polynomial models were built that reproduce the values of the breaking and pushing forces of the laminate with satisfactory accuracy. The selected algorithm for calculating the parameter values of these models is based on the application of the Chebyshev approximation of the functions of many variables. The optimization models built will allow, if necessary, for making corrections in the technological process of laminating printing prints to ensure the predicted required quality and strength of laminates.

References

- How to choose a base material for thermal laminating films (2022). Nobelus. Available at: https://nobelusuniversity.com/2022/09/01/how-to-choose-a-base-material-for-thermal-laminating-films/

- Grachyk, T. (1999). Laminowanie drukow ink – jetowych – ozhekiwania a stan obecny czesch. Poligrafika, 7, 58–60.

- What is lamination in printing? Available at: https://kaizenprint.co.uk/inspire-support/print-finishing-lamination/

- Kozlova, A. A., Kulak, M. I., Oleynik, R. S. (2015). Interrelation and influence of parameters of technological process on paper hardening at lamination. Trudi BGTU, 9, 24–28.

- Chepurna, K., Oliianenko, O. (2016). The Study of Adhesion of Polypropylene Films to the Surface of Printed Sheets of Electrophotographic Printing in the Lamination Process. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 4 (54), 39–48. doi: https://doi.org/10.20535/2077-7264.4(54).2016.86446

- Kyryliuk, A., Zorenko, O. (2011). Research of laminating of postals. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 4 (34), 46–56. doi: https://doi.org/10.20535/2077-7264.4(34).2011.33487

- Havenko, S., Dovhanych, A. (2021). Badanie czynników wpływających na jakość laminowania nadruków offsetowych. PRZEGLĄD PAPIERNICZY, 1 (11), 50–53. doi: https://doi.org/10.15199/54.2021.11.4

- Zyhulia, S. (2018). The Research of Strength Characteristics of Laminating Imprints. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 2 (60), 33–40. doi: https://doi.org/10.20535/2077-7264.2(60).2018.152031

- Chen, H., Jiang, B., Cai, Z.-Q. (2015). Preparation and properties of paper-plastic laminating adhesive used for medical packaging materials. Polymers for Advanced Technologies, 26 (9), 1065–1069. doi: https://doi.org/10.1002/pat.3533

- Angelski, D., Vitchev, P., Mihailov, V. (2017). Influences of some factors on adhesion strength between PVC foil and particle board. Pro Ligno, 13 (4), 302–307. Available at: https://www.researchgate.net/publication/322447803_INFLUENCES_OF_SOME_FACTORS_ON_ADHESION_STRENGTH_BETWEEN_PVC_FOIL_AND_PARTICLE_BOARD

- Havenko, S., Bernatsek, V., Labetska, M., Dovhanych, A. (2022). Study of the Influence of Lamination on the Quality of Digital Imprints. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 1 (75), 15–23. doi: https://doi.org/10.20535/2077-7264.1(75).2022.255484

- ISO 12647-2:2013. Graphic technology – Process control for the production of half-tone colour separations, proof and production prints – Part 2: Offset lithographic processes. Available at: https://www.iso.org/standard/57833.html

- Malachivskyy, P. S., Pizyur, Ya. V., Malachivskyi, R. P., Ukhanska, O. M. (2020). Chebyshev Approximation of Functions of Several Variables. Cybernetics and Systems Analysis, 56 (1), 118–125. doi: https://doi.org/10.1007/s10559-020-00227-8

- Bubela, T., Malachivskyy, P., Pokhodylo, Y., Mykyychuk, M., Vorobets, O. (2016). Mathematical modeling of soil acidity by the admittance parameters. Eastern-European Journal of Enterprise Technologies, 6 (10 (84)), 4–9. doi: https://doi.org/10.15587/1729-4061.2016.83972

- Malachivskyy, P. S., Pizyur, Ya. V., Danchak, N. V., Orazov, E. B. (2013). Chebyshev Approximation by Exponential-Power Expression. Cybernetics and Systems Analysis, 49 (6), 877–881. doi: https://doi.org/10.1007/s10559-013-9577-1

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Svitlana Havenko, Anna Dovhanych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.