Comparison of the moisture resistance of a steel-slag stone mastic asphalt mixture modified with Ca(OH)2

DOI:

https://doi.org/10.15587/1729-4061.2023.289054Keywords:

steel slag, stone mastic asphalt, Ca(OH)2, moisture resistance, Marshall stabilityAbstract

Stone mastic asphalt is a type of hot mix asphalt that requires much coarse aggregate, so substitution waste aggregate, such as steel slag, will be an economic reason. The problem is that there are still many things that have not been consistent in various studies related to the moisture resistance of steel slag.

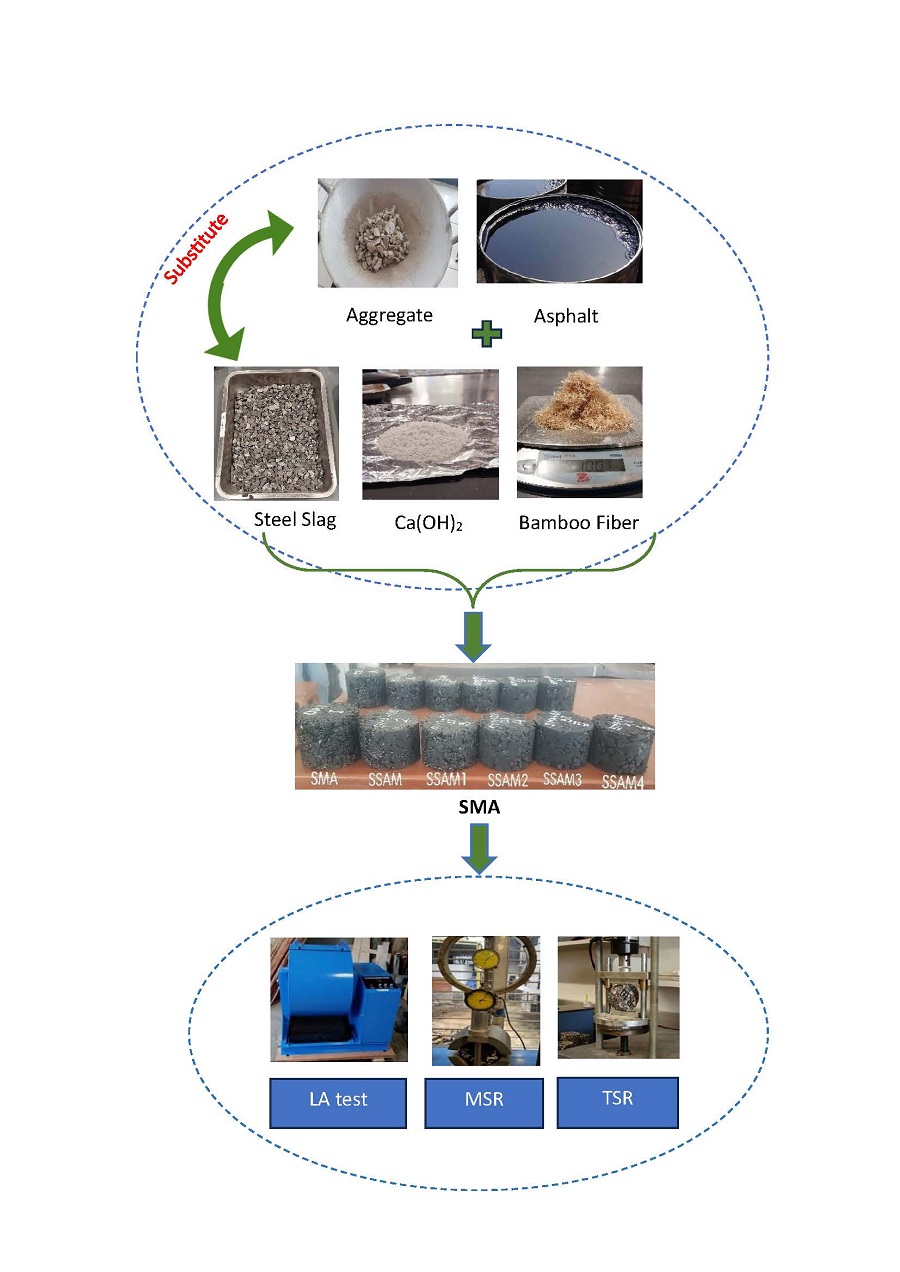

The study aimed to compare the effect of Ca(OH)2 on the moisture resistance of the steel-slag stone mastic asphalt mixture and to determine the optimal Ca(OH)2 dosage for improving the mixture resistance. This study employs basalt aggregate, steel slag from Krakatau Steel Company, 60/70 penetration asphalt, a stabilizing substance made of bamboo fiber, and Ca(OH)2.

The Texas boiling and the static immersed methods are used to test the adhesion on a loose mixture. The retained Marshall stability and indirect tensile strength are used to test the adhesion on the compacted mix.

Testing result of Krakatau steel slag shows that steel slag has a much higher Fe2O3 content than steel slag in general and has low water absorption; a poor affinity for asphalt results from this. The result of the Texas boiling method showed a decrease in the percentage adhesion value between steel slag and asphalt compared to natural basalt aggregates and asphalt. Marshall Stability Ratio and Tensile Strength Ratio increased after mixing the asphalt with Ca(OH)2. Marshall test results show decreased stability in mixtures with steel slag substitution. Adding Ca(OH)2 increased stability and resistance to moisture significantly. This indicated that Ca(OH)2 enhances moisture resistance on stone mastic asphalt with modified steel slag. Stability, Marshall stability ratio, indirect tensile strength ratio, particle loss, and Texas boiling test significantly improved with adding Ca(OH)2

Supporting Agency

- The authors thank the research team members for their guidance and support throughout LPPM Brawijaya University and the Ministries of Education, Culture, Research, and Technology Indonesia

References

- Liu, J., Wang, Z., Li, M., Wang, X., Wang, Z., Zhang, T. (2022). Microwave heating uniformity, road performance and internal void characteristics of steel slag asphalt mixtures. Construction and Building Materials, 353, 129155. doi: https://doi.org/10.1016/j.conbuildmat.2022.129155

- Qazizadeh, M. J., Farhad, H., Kavussi, A., Sadeghi, A. (2018). Evaluating the fatigue behavior of asphalt mixtures containing electric arc furnace and basic oxygen furnace slags using surface free energy estimation. Journal of Cleaner Production, 188, 355–361. doi: https://doi.org/10.1016/j.jclepro.2018.04.035

- Chien, H.-T., Chang, J.-R., Hsu, H.-M. (2023). Determining the content of steel furnace slag in asphalt concrete. Case Studies in Construction Materials, 19, e02399. doi: https://doi.org/10.1016/j.cscm.2023.e02399

- Fakhri, M., shahryari, E. (2021). The effects of nano zinc oxide (ZnO) and nano reduced graphene oxide (RGO) on moisture susceptibility property of stone mastic asphalt (SMA). Case Studies in Construction Materials, 15, e00655. doi: https://doi.org/10.1016/j.cscm.2021.e00655

- Gan, Y., Li, C., Ke, W., Deng, Q., Yu, T. (2022). Study on pavement performance of steel slag asphalt mixture based on surface treatment. Case Studies in Construction Materials, 16, e01131. doi: https://doi.org/10.1016/j.cscm.2022.e01131

- Liapis, I., Likoydis, S. (2012). Use of Electric Arc Furnace Slag in Thin Skid–Resistant Surfacing. Procedia - Social and Behavioral Sciences, 48, 907–918. doi: https://doi.org/10.1016/j.sbspro.2012.06.1068

- Mladenovič, A., Turk, J., Kovač, J., Mauko, A., Cotič, Z. (2015). Environmental evaluation of two scenarios for the selection of materials for asphalt wearing courses. Journal of Cleaner Production, 87, 683–691. doi: https://doi.org/10.1016/j.jclepro.2014.10.013

- Liu, J., Zhang, T., Guo, H., Wang, Z., Wang, X. (2022). Evaluation of self-healing properties of asphalt mixture containing steel slag under microwave heating: Mechanical, thermal transfer and voids microstructural characteristics. Journal of Cleaner Production, 342, 130932. doi: https://doi.org/10.1016/j.jclepro.2022.130932

- Caro, S., Masad, E., Bhasin, A., Little, D. N. (2008). Moisture susceptibility of asphalt mixtures, Part 1: mechanisms. International Journal of Pavement Engineering, 9 (2), 81–98. doi: https://doi.org/10.1080/10298430701792128

- Khodary, F., Abd El-sadek, M. S., El-Sheshtawy, H. S. (2014). Mechanical Properties Of Modified Asphalt Concrete Mixtures Using Ca(OH)2 Nanoparticles. International Journal of Civil Engineering and Technology (IJCIET), 5 (5), 61–68. Available at: https://iaeme.com/Home/article_id/IJCIET_05_05_006

- Kumlai, S., Jitsangiam, P., Nikraz, H. (2022). Assessments of moisture damage resistance of asphalt concrete mixtures and asphalt mastic with various mineral fillers. Transportation Engineering, 7, 100106. doi: https://doi.org/10.1016/j.treng.2022.100106

- Luo, W., Huang, S., Liu, Y., Peng, H., Ye, Y. (2022). Three-dimensional mesostructure model of coupled electromagnetic and heat transfer for microwave heating on steel slag asphalt mixtures. Construction and Building Materials, 330, 127235. doi: https://doi.org/10.1016/j.conbuildmat.2022.127235

- Lou, B., Sha, A., Li, Y., Wang, W., Liu, Z., Jiang, W., Cui, X. (2020). Effect of metallic-waste aggregates on microwave self-healing performances of asphalt mixtures. Construction and Building Materials, 246, 118510. doi: https://doi.org/10.1016/j.conbuildmat.2020.118510

- Terrel, R. L., Shute, J. W. (1989). Summary Report on WATER SENSITIVITY. S R-OSU-A-003A-89-3. Available at: https://onlinepubs.trb.org/Onlinepubs/shrp/shrp-A-IR-89-003/SHRP-AIR-003.pdf

- Bikerman, J. J. (1967). Causes of poor adhesion: weak boundary layers. Industrial & Engineering Chemistry, 59 (9), 40–44. doi: https://doi.org/10.1021/ie51403a010

- Pstrowska, K., Gunka, V., Sidun, I., Demchuk, Y., Vytrykush, N., Kułażyński, M., Bratychak, M. (2022). Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods. Coatings, 12 (12), 1934. doi: https://doi.org/10.3390/coatings12121934

- Moura, B. L. R. de, Teixeira, J. E. S. L., Simão, R. A., Khedmati, M., Kim, Y.-R., Pires, P. J. M. (2020). Adhesion between steel slag aggregates and bituminous binder based on surface characteristics and mixture moisture resistance. Construction and Building Materials, 264, 120685. doi: https://doi.org/10.1016/j.conbuildmat.2020.120685

- Phan, T. M., Park, D.-W., Le, T. H. M. (2018). Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Construction and Building Materials, 180, 503–511. doi: https://doi.org/10.1016/j.conbuildmat.2018.05.278

- Zhang, S., Guo, R., Yan, F., Dong, R., Kong, C., Li, J. (2023). Analysis of Asphalt Mixtures Modified with Steel Slag Surface Texture Using 3D Scanning Technology. Materials, 16 (8), 3256. doi: https://doi.org/10.3390/ma16083256

- Desvita, M. D., Djakfar, L., Wisnumurti, W., Prasetia, M. S., Febriansyah, M. C. (2023). The role of addition of calcium alginate microcapsules on permanent deformation of AC–WC natural asphalt Buton stone in Indonesia. Eastern-European Journal of Enterprise Technologies, 3 (6 (123)), 88–95. doi: https://doi.org/10.15587/1729-4061.2023.280067

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Irawati Irawati, Ludfi Djakfar, Muhammad Zainul Arifin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.