Improving the quality of processing the soil environment by determining the rational structural and technological parameters for the rolling working bodies

DOI:

https://doi.org/10.15587/1729-4061.2023.289238Keywords:

layer-by-layer soil density, heterogeneity of soil density, ring-spur roller, ring-tooth rollerAbstract

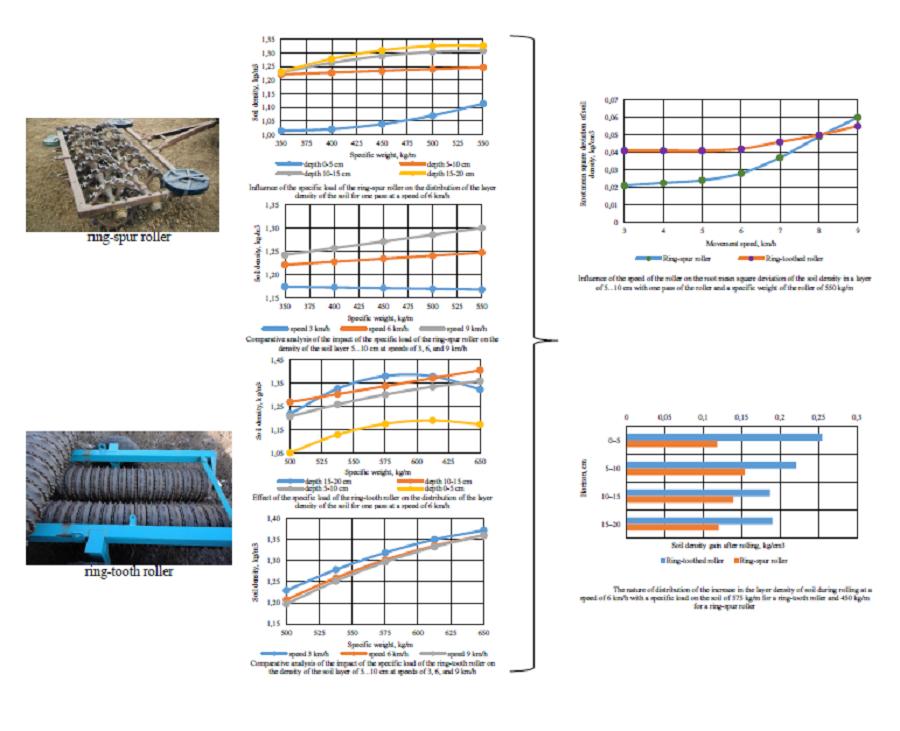

The object of this study is the process of soil compaction with ring-spur and ring-tooth rollers. Based on the zonal optimization of the agrophysical parameters of the arable horizon, the influence of the rolling working bodies on the soil environment in terms of creating a uniform set layer density during pre-sowing tillage was investigated. It was established that soil density should be evaluated in a zonal section together with its aggregate composition, humus content, moisture, etc. Smooth-water-filled, ring-tooth, and ring-spur rollers were studied. The use of a smooth water-filled roller in previous studies contributed to the high unevenness of the compaction of the upper and lower layers of the arable horizon, which indicated the impracticality of further experiments. The research of ring-tooth and ring-spur rollers was carried out by the method of a multifactorial experiment under defined soil and climatic conditions (soil type, sod-podzolic; layer-by-layer soil moisture, 26...28 %; layer-by-layer soil density, 0.96...1.25 g/cm3). Regression models were built of the influence of the specific load, the frequency of passes, and the working speed of the unit on the density of the soil in layers: 0–5; 5–10; 10–15; 15–20; 20–25; 25–30 cm. To assess the heterogeneity of soil density in layers 0–5 and 5–10 cm, a data array was constructed. It was established that the ring-spur roller, even at a speed of up to 6 km/h, is not a tool suitable for regulating the equilibrium density of the seed layer. The best for pre-sowing soil cultivation is a ring-tooth roller (specific soil load, 350 kg/m; unit speed up to 6 km/h).

The derived regression equations make it possible to select such a specific load on the ring-tooth roller that could provide a rational value of the layer density of the soil. This is economically and environmentally expedient.

References

- Wang, Y., Zhang, Z., Guo, Z., Chen, Y., Yang, J., Peng, X. (2023). In-situ measuring and predicting dynamics of soil bulk density in a non-rigid soil as affected by tillage practices: Effects of soil subsidence and shrinkage. Soil and Tillage Research, 234, 105818. doi: https://doi.org/10.1016/j.still.2023.105818

- Alletto, L., Pot, V., Giuliano, S., Costes, M., Perdrieux, F., Justes, E. (2015). Temporal variation in soil physical properties improves the water dynamics modeling in a conventionally-tilled soil. Geoderma, 243-244, 18–28. doi: https://doi.org/10.1016/j.geoderma.2014.12.006

- Canali, S., Campanelli, G., Ciaccia, C., Leteo, F., Testani, E., Montemurro, F. (2013). Conservation tillage strategy based on the roller crimper technology for weed control in Mediterranean vegetable organic cropping systems. European Journal of Agronomy, 50, 11–18. doi: https://doi.org/10.1016/j.eja.2013.05.001

- Wen, L., Peng, Y., Zhou, Y., Cai, G., Lin, Y., Li, B. (2023). Effects of conservation tillage on soil enzyme activities of global cultivated land: A meta-analysis. Journal of Environmental Management, 345, 118904. doi: https://doi.org/10.1016/j.jenvman.2023.118904

- Sharma, S., Singh, P. (2023). Tillage intensity and straw retention impacts on soil organic carbon, phosphorus and biological pools in soil aggregates under rice-wheat cropping system in Punjab, north-western India. European Journal of Agronomy, 149, 126913. doi: https://doi.org/10.1016/j.eja.2023.126913

- Douglas, J. T., Koppi, A. J. (1997). Soil structural quality: a case study of soil macropore attributes after seedbed preparation with different wheel traffic systems. Soil and Tillage Research, 41 (3-4), 249–259. doi: https://doi.org/10.1016/s0167-1987(96)01096-3

- James, I. T., Shipton, P. M. R. (2012). Quantifying compaction under rollers using marker tracing image analysis. Soil and Tillage Research, 120, 40–49. doi: https://doi.org/10.1016/j.still.2012.01.006

- Tong, J., Zhang, Q., Guo, L., Chang, Y., Guo, Y., Zhu, F. et al. (2015). Compaction Performance of Biomimetic Press Roller to Soil. Journal of Bionic Engineering, 12 (1), 152–159. doi: https://doi.org/10.1016/s1672-6529(14)60109-8

- Tong, J., Zhang, Q., Chang, Y., Chen, D., Dong, W., Zhang, L. (2014). Reduction of soil adhesion and traction resistance of ridged bionic press roller. Transactions of the Chinese Society for Agriculture Machinery, 45, 135–140.

- Rücknagel, J., Rücknagel, S., Christen, O. (2012). Impact on soil compaction of driving agricultural machinery over ground frozen near the surface. Cold Regions Science and Technology, 70, 113–116. doi: https://doi.org/10.1016/j.coldregions.2011.09.004

- Colombi, T., Torres, L. C., Walter, A., Keller, T. (2018). Feedbacks between soil penetration resistance, root architecture and water uptake limit water accessibility and crop growth – A vicious circle. Science of The Total Environment, 626, 1026–1035. doi: https://doi.org/10.1016/j.scitotenv.2018.01.129

- Premrov, A., Cummins, T., Byrne, K. A. (2018). Bulk-density modelling using optimal power-transformation of measured physical and chemical soil parameters. Geoderma, 314, 205–220. doi: https://doi.org/10.1016/j.geoderma.2017.10.060

- Altikat, S., Celik, A. (2011). The effects of tillage and intra-row compaction on seedbed properties and red lentil emergence under dry land conditions. Soil and Tillage Research, 114 (1), 1–8. doi: https://doi.org/10.1016/j.still.2011.03.003

- Mileusnić, Z. I., Saljnikov, E., Radojević, R. L., Petrović, D. V. (2022). Soil compaction due to agricultural machinery impact. Journal of Terramechanics, 100, 51–60. doi: https://doi.org/10.1016/j.jterra.2021.12.002

- Moinfar, A., Shahgholi, G., Gilandeh, Y. A., Kaveh, M., Szymanek, M. (2022). Investigating the effect of the tractor driving system type on soil compaction using different methods of ANN, ANFIS and step wise regression. Soil and Tillage Research, 222, 105444. doi: https://doi.org/10.1016/j.still.2022.105444

- Golub, G., Chuba, V., Achkevych, V., Krushelnytskyi, V., Tsyvenkova, N. (2023). Modeling of the running system pressure on the soil depending on the structural parameters of the tractors. INMATEH Agricultural Engineering, 69 (1), 369–378. doi: https://doi.org/10.35633/inmateh-69-34

- Kushnarev, A. S., Kochev, V. I. (1989). Mekhaniko-tekhnologicheskie osnovy obrabotki pochvy. Kyiv: Urozhay, 144.

- Kachinskiy, N. A. (1958). Otsenka osnovnykh fizicheskikh svoystv pochv v agronomicheskikh tselyakh i prirodnogo plodorodiya po ikh mekhanicheskomu sostavu. Pochvovedenie, 5, 10–13.

- Bulyhin, S. Yu., Vitvitskyi, S. V. (2021). Ahrofizyka gruntu. Kyiv: Vydavnytstvo, 315.

- Hutsol, O. P., Kovbasa, V. P. (2016). Obgruntuvannia parametriv i rezhymiv rukhu gruntoobrobnykh mashyn z dyskovymy robochymy orhanamy. Kyiv, 145.

- Shevchenko, I. A., Alba, V. D. (1994). Vliyanie pokazateley raboty kol'chato-zubovogo katka na izmenenie plotnosti pochvy i urozhay sel'skokhozyaystvennykh kul'tur. Trudy mezhdunarodnoy konf. «Modelirovanie protsessov i tekhnologicheskogo oborudovaniya v s.kh.». Melitopol': TGATA, 34–39.

- Shevchenko, I. A. (2002). Obgruntuvannia tekhnolohiy ta tekhnichnykh zasobiv dlia obrobitku gruntiv na bazi yikh ahrofizychnykh pokaznykiv. Kyiv, 382.

- Shustik, L., Pogoriliy, V., Nilova, N., Gaiday, T., Stepchenko, S., Sidorenko, S. (2020). Rollers of different constructions. Engineering analysis. Technical and Technological Aspects of Development and Testing of New Machinery and Technologies for Agriculture of Ukraine, 27 (41). doi: https://doi.org/10.31473/2305-5987-2020-2-27(41)-9

- Shustik, L., Pogoriliy, V., Nilova, N., Gaidai, T., Stepchenko, S., Sidorenko, S. (2021). Crosskill and star-wheeled rollers. Functional and dynamic tests. Technical and Technological Aspects of Development and Testing of New Machinery and Technologies for Agriculture of Ukraine, 28 (42). doi: https://doi.org/10.31473/2305-5987-2021-1-28(42)-7

- Salem, H. M., Valero, C., Muñoz, M. Á., Gil-Rodríguez, M. (2015). Effect of integrated reservoir tillage for in-situ rainwater harvesting and other tillage practices on soil physical properties. Soil and Tillage Research, 151, 50–60. doi: https://doi.org/10.1016/j.still.2015.02.009

- Vazhynskyi, S. E., Shcherbak, T. I. (2016). Metodyka ta orhanizatsiya naukovykh doslidzhen. Sumy: SumDPU imeni A. S. Makarenka, 260.

- Bobyliev, V. P., Ivanov, I. I., Proidak, Yu. S. (2014). Metodolohiya ta orhanizatsiia naukovykh doslidzhen. Dnipropetrovsk: IMA-press, 643.

- Asoodar, M., Mohajer, F. (2009). Effects of different tillage and press wheel weight on dryland wheat grain production. Technology and Management to Increase the Efficiency in Sustainable Agricultural Systems. Rosario. Available at: https://journals.sfu.ca/cigrp/index.php/Proc/article/view/103

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Igor Shevchenko, Gennadii Golub, Nataliya Tsyvenkova, Iryna Shevchenko, Vladyslav Shubenko, Oleksandr Medvedskyi, Oleh Pluzhnikov, Ivan Omarov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.