Evaluating the impact of structure parameters on the acoustic performance of an exhaust muffler with shells

DOI:

https://doi.org/10.15587/1729-4061.2023.289250Keywords:

exhaust mufflers, acoustics, noise control, combustion engines, sound transmission loss, SPLAbstract

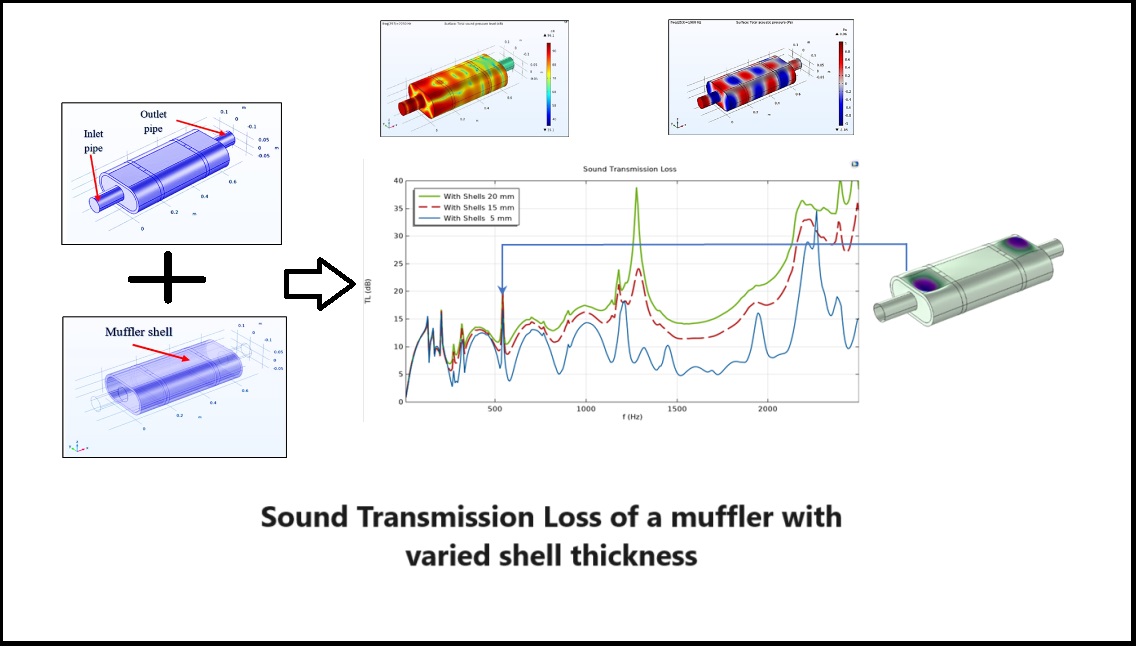

Recently, environmental noise has arisen from various sources, such as those from exhaust mufflers of combustion engines found in cars, trucks, or power generators, which produce significant noise during their operation. Controlling the radiated noise from these mufflers is a major factor in improving acoustic comfort and minimizing the impact on the surrounding communities. Numerous research has been presented for this reason by modification of the internal structure of the exhaust muffler. The main objective of this work is to reduce the noise level emitted from exhaust mufflers. This can be achieved by adjusting structure parameters to attenuate the surrounding environment's radiated noise. Analysis of pressure-wave propagation has been done by building 3D models using COMSOL Multiphysics software. Different entities were conducted to investigate the influence of muffler shells and plate thicknesses on acoustic performance through the frequency domain to obtain better attenuation. SPL over a frequency band is presented, describing how the sound intensity varies at different frequencies within a given bandwidth. The results showed that increasing the muffler shell thickness improved the TL; this particularly causes a double value at a range above 1.2 kHz, where there are two distinct peaks at 1.3 kHz and 2.8 kHz. Additionally, it was found that increasing the muffler plate thickness reduces the TL whole range and moves the curve peak to higher frequencies.

This is because the pressure pulses that stimulate the shell plates would exert a more distinct influence on plates characterized by a reduced thickness, and the muffler structure thickness is correlated with its increased stiffness, resulting in an elevation of the frequency for this eigenmode

References

- Zhong, W., Pachiannan, T., Li, Z., Qian, Y., Zhang, Y., Wang, Q. et al. (2019). Combustion and emission characteristics of gasoline/hydrogenated catalytic biodiesel blends in gasoline compression ignition engines under different loads of double injection strategies. Applied Energy, 251, 113296. doi: https://doi.org/10.1016/j.apenergy.2019.05.099

- Xia, Q., Wang, K., Han, Z., Tian, W. (2019). A comparative study of combustion and emission characteristics of butanol isomers on a diesel engine with dual fuel butanol isomers/diesel compound combustion. Fuel, 254, 115581. doi: https://doi.org/10.1016/j.fuel.2019.05.164

- Ashok Reddy, K. (2017). A Critical Review on Acoustic Methods & Materials of a Muffler. Materials Today: Proceedings, 4 (8), 7313–7334. doi: https://doi.org/10.1016/j.matpr.2017.07.061

- Yasuda, T., Wu, C., Nakagawa, N., Nagamura, K. (2010). Predictions and experimental studies of the tail pipe noise of an automotive muffler using a one dimensional CFD model. Applied Acoustics, 71 (8), 701–707. doi: https://doi.org/10.1016/j.apacoust.2010.03.001

- Mimani, A., Munjal, M. L. (2012). 3-D acoustic analysis of elliptical chamber mufflers having an end-inlet and a side-outlet: An impedance matrix approach. Wave Motion, 49 (2), 271–295. doi: https://doi.org/10.1016/j.wavemoti.2011.11.001

- Mimani, A., Munjal, M. L. (2011). Transverse plane wave analysis of short elliptical chamber mufflers: An analytical approach. Journal of Sound and Vibration, 330 (7), 1472–1489. doi: https://doi.org/10.1016/j.jsv.2010.09.035

- Jena, D. P., Panigrahi, S. N. (2017). Numerically estimating acoustic transmission loss of a reactive muffler with and without mean flow. Measurement, 109, 168–186. doi: https://doi.org/10.1016/j.measurement.2017.05.065

- Antebas, A. G., Denia, F. D., Pedrosa, A. M., Fuenmayor, F. J. (2013). A finite element approach for the acoustic modeling of perforated dissipative mufflers with non-homogeneous properties. Mathematical and Computer Modelling, 57 (7-8), 1970–1978. doi: https://doi.org/10.1016/j.mcm.2012.01.021

- Hacham, W. S., Hiji, F. S. (2020). Impact of using Double Layers Perforated Liners on the Acoustic Treatments of the Combustor Systems. Al-Khwarizmi Engineering Journal, 16 (4), 19–26. doi: https://doi.org/10.22153/kej.2020.10.002

- Ouédraogo, B., Maréchal, R., Ville, J.-M., Perrey-Debain, E. (2016). Broadband noise reduction by circular multi-cavity mufflers operating in multimodal propagation conditions. Applied Acoustics, 107, 19–26. doi: https://doi.org/10.1016/j.apacoust.2016.02.001

- Kashikar, A., Suryawanshi, R., Sonone, N., Thorat, R., Savant, S. (2021). Development of muffler design and its validation. Applied Acoustics, 180, 108132. doi: https://doi.org/10.1016/j.apacoust.2021.108132

- Fu, J., Xu, M., Zheng, W., Zhang, Z., He, Y. (2021). Effects of structural parameters on transmission loss of diesel engine muffler and analysis of prominent structural parameters. Applied Acoustics, 173, 107686. doi: https://doi.org/10.1016/j.apacoust.2020.107686

- Rafique, F., Hui Wu, J., Rui Liu, C., Ma, F. (2022). Transmission Loss analysis of a simple expansion chamber muffler with extended inlet and outlet combined with inhomogeneous micro-perforated panel (iMPP). Applied Acoustics, 194, 108808. doi: https://doi.org/10.1016/j.apacoust.2022.108808

- Kalita, U., Singh, M. (2023). Acoustic performance analysis of muffler by varying sound absorption materials. Materials Today: Proceedings. doi: https://doi.org/10.1016/j.matpr.2023.02.272

- Fu, J., Zheng, W., Xu, M., Wang, W., Huang, Y. (2021). Study on the influence of structure factors of diesel engine exhaust purification muffler on transmission loss in different frequency bands. Applied Acoustics, 180, 108147. doi: https://doi.org/10.1016/j.apacoust.2021.108147

- COMSOL Multiphysics Reference Manual. Available at: https://doc.comsol.com/5.5/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf

- Prasad, A., Thiagarajan, R. C. (2015). Acoustic Performance Design of Automotive Muffler. Excerpt from the Proceedings of the 2015 COMSOL Conference in Pune. Available at: https://www.researchgate.net/publication/350063080_Acoustic_Performance_Design_of_Automotive_Muffler

- Kalita, U., Singh, M. (2023). Optimization of reactive muffler through pressure acoustic analysis and Taguchi approach. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 45 (2). doi: https://doi.org/10.1007/s40430-023-04023-1

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ali I. Mosa, Azma Putra, Hussein A. Mahmood

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.