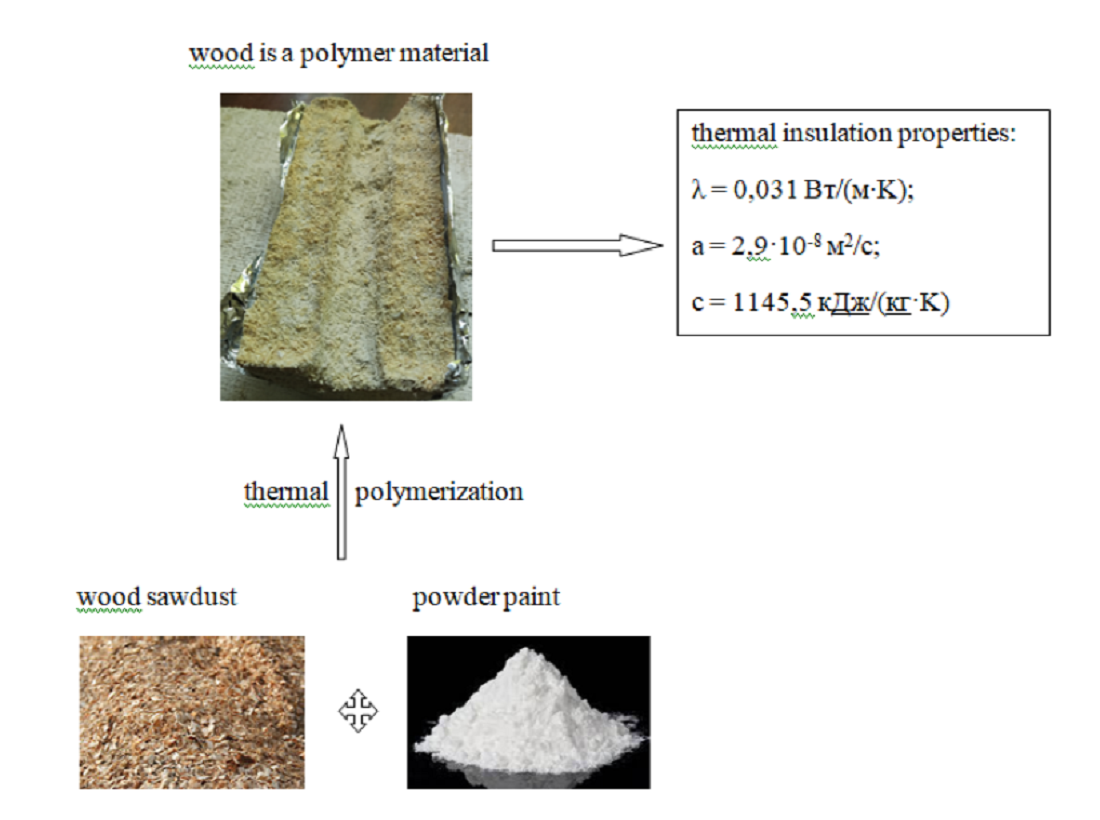

Determining thermal and physical characteristics of wood polymer material for pipeline thermal insulation

DOI:

https://doi.org/10.15587/1729-4061.2023.289341Keywords:

wood sawdust, binder resins, wood polymer material, thermal insulation of the pipeline, thermal conductivityAbstract

One of the methods for ensuring the efficiency of pipelines for transporting heat-carriers during operation is their thermal insulation, which inhibits heat transfer processes and does not affect environmental indicators. Therefore, the object of research was wood, a polymer material made by polymerization of wood sawdust and dry mixtures of synthetic resins for thermal insulation of pipelines. It has been proven that in the process of thermal action on the heat insulating layer of wood polymer material, the process of heat inhibition involves the formation of pores. This is due to the fact that the thermal conductivity of the material depends on the volumetric mass, the decrease of which for a wood polymer product leads to a decrease in thermal conductivity. In this regard, the simulation of the process of heat transfer through a cylindrical heat-insulating layer made of wood of polymer material was carried out and the dependences derived, which allow obtaining a change in the dynamics of heat transfer and determining thermophysical properties. According to the experimental data and the established dependences, it was found that the thermal conductivity of the wood of the polymer material was within 2.4÷2.9·10-8 m2/s, the thermal conductivity of the sample did not exceed 0.030 W/(m∙K). In addition, the heat capacity of the product corresponds to a value of more than 1034÷1145 kJ/(kg·K) depending on the thickness, which accordingly categorizes it as a heat-insulating material. At the same time, data on thermal insulation properties for polyurethane foam show that when it is used with a density of 100 kg/m3, the thermal conductivity is 0.029 W/(m∙K), which is approximately the same as the value of the proposed wood polymer material. The practical value is the fact that the results of determining the heat-insulating properties of a wood polymer material make it possible to establish the scope and conditions of its application

References

- Terhan, M. (2022). Optimization insulation thickness and reduction of CO2 emissions for pipes in all generation district heating networks. Science Progress, 105 (3), 003685042211222. doi: https://doi.org/10.1177/00368504221122287

- Lugovoi, P., Shugailo, O., Orlenko, V., Diemienkov, V. (2020). Oscillation of Thermal Insulation Three-Layer Cylindrical Pipes under Operating Loads. Nuclear and Radiation Safety, 3 (87), 55–61. doi: https://doi.org/10.32918/nrs.2020.3(87).07

- Jakubek, D., Ocłoń, P., Nowak-Ocłoń, M., Sułowicz, M., Varbanov, P. S., Klemeš, J. J. (2023). Mathematical modelling and model validation of the heat losses in district heating networks. Energy, 267, 126460. doi: https://doi.org/10.1016/j.energy.2022.126460

- Pan, Y., Cheng, X., Yan, M., He, P., Zhang, H. (2023). Silica aerogel and its application in the field of thermal insulation. Chemical Industry and Engineering Progress, 42 (1), 297–309. doi: https://doi.org/10.16085/j.issn.1000-6613.2022-0512

- Suresh, S., Sundar, M., Lokavarapu, B. R. (2023). Optimum insulation thickness in process pipelines. Materials Today: Proceedings. doi: https://doi.org/10.1016/j.matpr.2023.01.200

- Jing, M., Zhang, S., Fu, L., Cao, G., Wang, R. (2023). Reducing heat losses from aging district heating pipes by using cured-in-place pipe liners. Energy, 273, 127260. doi: https://doi.org/10.1016/j.energy.2023.127260

- Zhu, J., Li, X., Li, D., Jiang, C. (2022). Thermal Insulation and Flame Retardancy of the Hydroxyapatite Nanorods/Sodium Alginate Composite Aerogel with a Double-Crosslinked Structure. ACS Applied Materials & Interfaces, 14 (40), 45822–45831. doi: https://doi.org/10.1021/acsami.2c12254

- De Rosa, M., Bianco, V. (2023). Optimal insulation layer for heated water pipes under technical, economic and carbon emission constraints. Energy, 270, 126961. doi: https://doi.org/10.1016/j.energy.2023.126961

- Küçüktopcu, E., Cemek, B., Simsek, H. (2022). The Economic and Environmental Impact of Greenhouse Heating Pipe Insulation. Sustainability, 14 (1), 549. doi: https://doi.org/10.3390/su14010549

- Zhao, Y., Dieckmann, E., Cheeseman, C. (2020). Low-temperature thermal insulation materials with high impact resistance made from feather-fibres. Materials Letters: X, 6, 100039. doi: https://doi.org/10.1016/j.mlblux.2020.100039

- Jiang, D., Wang, Y., Li, B., Sun, C., Guo, Z. (2020). Environmentally friendly alternative to polyester polyol by corn straw on preparation of rigid polyurethane composite. Composites Communications, 17, 109–114. doi: https://doi.org/10.1016/j.coco.2019.11.007

- Alamnia, A. T., Samuel Fatoba, O., Jen, T.-C. (2022). Heat Transfer Investigation in Natural Fibers Insulation for Steam Pipes Application. 2022 IEEE 13th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT). doi: https://doi.org/10.1109/icmimt55556.2022.9845292

- Zhang, L., Zou, Y., Yang, Y., Chen, X., Dai, Y., Zhou, C., Xu, H. (2023). Design and optimization of thermal insulation structure for high-temperature pipeline inside the lower tank wall. Annals of Nuclear Energy, 192, 109988. doi: https://doi.org/10.1016/j.anucene.2023.109988

- Banushi, G., Vega, A., Weidlich, I., Yarahmadi, N., Kim, J., Jakubowicz, I., Sällström, J. H. (2021). Durability of District Heating Pipelines Exposed to Thermal Aging and Cyclic Operational Loads. Journal of Pipeline Systems Engineering and Practice, 12 (1). doi: https://doi.org/10.1061/(asce)ps.1949-1204.0000521

- Tsapko, Y., Likhnyovskyi, R., Buiskykh, N., Horbachova, O., Mazurchuk, S., Lastivka, O. et al. (2023). Determining patterns in the formation of a polymer shell by powder paint on wood surface. Eastern-European Journal of Enterprise Technologies, 1 (10 (121)), 37–45. doi: https://doi.org/10.15587/1729-4061.2023.273364

- DSTU B V.2.6-189:2013. Methods for choosing of insulation material for insulation of buildings (2014). Kyiv: Minrehion Ukrainy.

- DSTU B V.2.7-105-2000. Metod vyznachennia teploprovidnosti i termichnoho oporu pry statsionarnomu teplovomu rezhymi (2001). Kyiv: Derzhbud.

- Tsapko, Y., Zavialov, D., Bondarenko, O., Marchenco, N., Mazurchuk, S., Horbachova, O. (2019). Determination of thermal and physical characteristics of dead pine wood thermal insulation products. Eastern-European Journal of Enterprise Technologies, 4 (10 (100)), 37–43. doi: https://doi.org/10.15587/1729-4061.2019.175346

- Janna, W. S. (2010). Engineering Heat Transfer. CRC Press, 692. Available at: https://www.routledge.com/Engineering-Heat-Transfer/Janna/p/book/9781420072020

- Potter, M. C. (2018). Engineering analysis. Springer, 434. doi: https://doi.org/10.1007/978-3-319-91683-5

- Cengel, Y. A. (2009). Introduction to Thermodynamics and Heat Transfer. McGraw-Hill, 960.

- DIN EN 253:2009. District Heating Pipes - Preinsulated Bonded Pipe Systems For Directly Buried Hot Water Networks - Pipe Assembly Of Steel Service Pipe, Polyurethane Thermal Insulation And Outer Casing Of Polyethylene. Available at: https://webstore.ansi.org/standards/din/dinen2532009

- Tsapko, Y., Rogovskii, I., Titova, L., Bilko, T., Tsapko, А., Bondarenko, O., Mazurchuk, S. (2020). Establishing regularities in the insulating capacity of a foaming agent for localizing flammable liquids. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 51–57. doi: https://doi.org/10.15587/1729-4061.2020.215130

- Tsapko, Y., Likhnyovskyi, R., Tsapko, А., Kovalenko, V., Slutska, O., Illiuchenko, P. et al. (2023). Determining the patterns of extinguishing polar flammable liquids with a film-forming foaming agent. Eastern-European Journal of Enterprise Technologies, 3 (10 (123)), 48–56. doi: https://doi.org/10.15587/1729-4061.2023.278910

- Tsapko, Y., Horbachova, O., Tsapko, А., Mazurchuk, S., Zavialov, D., Buiskykh, N. (2021). Establishing regularities in the propagation of phase transformation front during timber thermal modification. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 30–36. doi: https://doi.org/10.15587/1729-4061.2021.225310

- Tsapko, Y., Rogovskii, I., Titova, L., Shatrov, R., Tsapko, А., Bondarenko, O., Mazurchuk, S. (2020). Establishing patterns of heat transfer to timber through a protective structure. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 65–71. doi: https://doi.org/10.15587/1729-4061.2020.217970

- Tsapko, Y., Lomaha, V., Vasylyshyn, R., Melnyk, O., Balanyuk, V., Tsapko, А. et al. (2022). Establishing regularities in the reduction of flammable properties of wood protected with two-component intumescent varnish. Eastern-European Journal of Enterprise Technologies, 3 (10 (117)), 63–71. doi: https://doi.org/10.15587/1729-4061.2022.259582

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuriy Tsapko, Ivan Kasianchuk, Ruslan Likhnyovskyi, Аleksii Tsapko, Vitalii Kovalenko, Vadym Nizhnyk, Olga Bedratiuk, Maryna Sukhanevych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.