Development of bioplastics from Tawaro's environmentally friendly sago starch (metroxylon)

DOI:

https://doi.org/10.15587/1729-4061.2023.289626Keywords:

X-ray diffraction, Tawaro starch, ultraviolet radiation treatment, mechanical propertiesAbstract

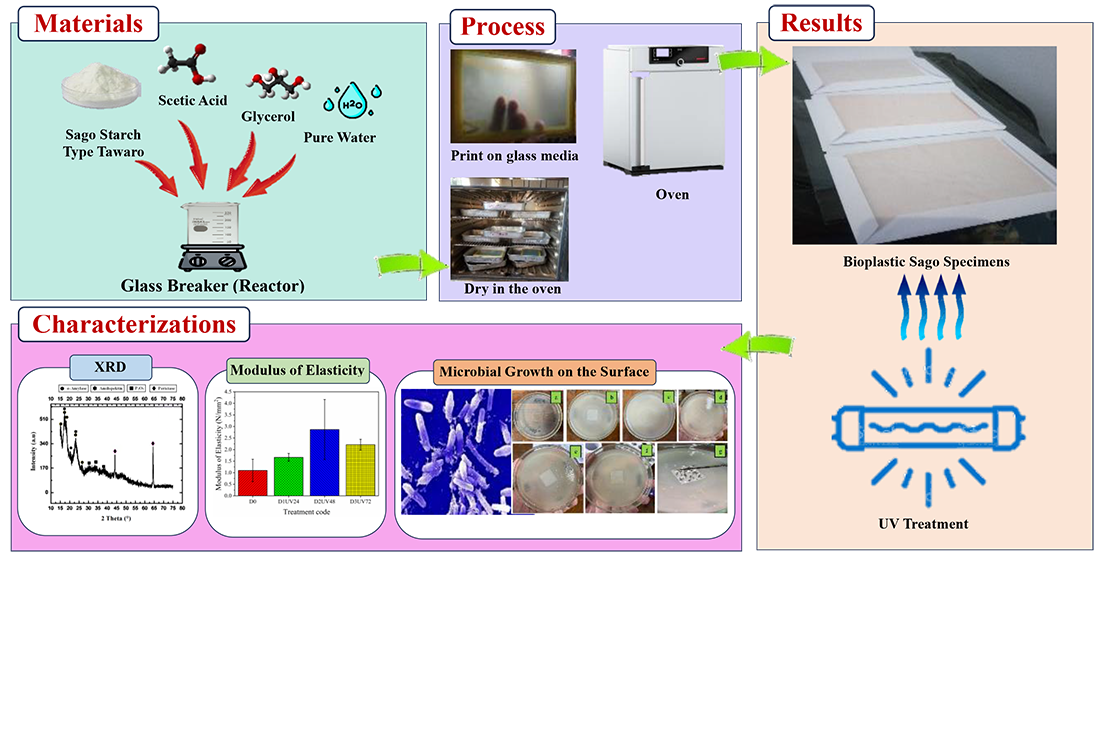

Sustainable bioplastics made from Tawaro sago starch are investigated in the study. This study is motivated by the global need to lessen the environmental impact of petroleum-based polymers and discover greener alternatives. Tawaro sago starch's amylose concentration, moisture levels, and ecologically friendly qualities are examined in the study. It carefully blends sago starch, glycerol, and an acetic acid and water activator solution to create a bioplastic. The study will examine these bioplastics' chemical composition, crystalline structure, mechanical properties, and reactions to UV radiation and microbial development. Researchers and developers are interested in sago starch, a staple meal in Palopo City, South Sulawesi Province, Indonesia, as a sustainable material. Sago starch is advantageous due to its renewable nature and eco-friendly properties. XRD, mechanical characteristics, and microbiological development in sago bioplastic are examined in the study, providing valuable insights. Tawaro sago bioplastic has no heavy metals, according to XRD. The mechanical characteristics have improved significantly, reaching 2,867 N/mm². A 48-hour UV radiation exposure within limitations changed the chemical chain, causing the improvement. Furthermore, bacteria grow swiftly on sago bioplastic. This research promotes sago-based bioplastics as an eco-friendly alternative to traditional plastics, promoting environmental sustainability. This research supports the global drive to create eco-friendly materials. Using Tawaro sago starch, creative solutions for a greener, more sustainable future are possible, with bioplastics offering a compelling alternative to existing plastics and lowering their environmental impact.

Supporting Agency

- The author expresses gratitude to the sago processing area in Mancani Village, Telluwanua District, Palopo City, South Sulawesi Province, Indonesia, for providing the raw materials used in this research.

References

- Dirpan, A., Hidayat, S. H., Djalal, M., Ainani, A. F., Yolanda, D. S., Kasmira, Khosuma, M. et al. (2023). Trends over the last 25 years and future research into smart packaging for food: A review. Future Foods, 8, 100252. doi: https://doi.org/10.1016/j.fufo.2023.100252

- Chowdhury, M. A., Nayem Hossain, Badrudduza, M. D., Rana, Md. M. (2023). Development and characterization of natural sourced bioplastic for food packaging applications. Heliyon, 9 (2), e13538. doi: https://doi.org/10.1016/j.heliyon.2023.e13538

- Sun, X. S. (2013). Overview of Plant Polymers. Handbook of Biopolymers and Biodegradable Plastics, 1–10. doi: https://doi.org/10.1016/b978-1-4557-2834-3.00001-x

- Soroudi, A., Jakubowicz, I. (2013). Recycling of bioplastics, their blends and biocomposites: A review. European Polymer Journal, 49 (10), 2839–2858. doi: https://doi.org/10.1016/j.eurpolymj.2013.07.025

- Perez-Puyana, V., Cuartero, P., Jiménez-Rosado, M., Martínez, I., Romero, A. (2022). Physical crosslinking of pea protein-based bioplastics: Effect of heat and UV treatments. Food Packaging and Shelf Life, 32, 100836. doi: https://doi.org/10.1016/j.fpsl.2022.100836

- Altskar, A., Andersson, R., Boldizar, A., Koch, K., Stading, M., Rigdahl, M., Thunwall, M. (2008). Some effects of processing on the molecular structure and morphology of thermoplastic starch. Carbohydrate Polymers, 71 (4), 591–597. doi: https://doi.org/10.1016/j.carbpol.2007.07.003

- Anugrahwidya, R., Armynah, B., Tahir, D. (2021). Bioplastics Starch-Based with Additional Fiber and Nanoparticle: Characteristics and Biodegradation Performance: A Review. Journal of Polymers and the Environment, 29 (11), 3459–3476. doi: https://doi.org/10.1007/s10924-021-02152-z

- Cai, L., Wang, J., Peng, J., Wu, Z., Tan, X. (2018). Observation of the degradation of three types of plastic pellets exposed to UV irradiation in three different environments. Science of The Total Environment, 628-629, 740–747. doi: https://doi.org/10.1016/j.scitotenv.2018.02.079

- Souza, A. C., Benze, R., Ferrão, E. S., Ditchfield, C., Coelho, A. C. V., Tadini, C. C. (2012). Cassava starch biodegradable films: Influence of glycerol and clay nanoparticles content on tensile and barrier properties and glass transition temperature. LWT - Food Science and Technology, 46 (1), 110–117. doi: https://doi.org/10.1016/j.lwt.2011.10.018

- Mostafa, N. A., Farag, A. A., Abo-dief, H. M., Tayeb, A. M. (2018). Production of biodegradable plastic from agricultural wastes. Arabian Journal of Chemistry, 11 (4), 546–553. doi: https://doi.org/10.1016/j.arabjc.2015.04.008

- Bidari, R., Abdillah, A. A., Ponce, R. A. B., Charles, A. L. (2023). Characterization of Biodegradable Films Made from Taro Peel (Colocasia esculenta) Starch. Polymers, 15 (2), 338. doi: https://doi.org/10.3390/polym15020338

- Santana, R. F., Bonomo, R. C. F., Gandolfi, O. R. R., Rodrigues, L. B., Santos, L. S., dos Santos Pires, A. C. et al. (2017). Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. Journal of Food Science and Technology, 55(1), 278–286. doi: https://doi.org/10.1007/s13197-017-2936-6

- Yang, J., Ching, Y. C., Chuah, C. H., Liou, N.-S. (2020). Preparation and Characterization of Starch/Empty Fruit Bunch-Based Bioplastic Composites Reinforced with Epoxidized Oils. Polymers, 13 (1), 94. doi: https://doi.org/10.3390/polym13010094

- Zuraida, A., Anuar, H., Yusof, Y. (2011). The Study of Biodegradable Thermoplastics Sago Starch. Key Engineering Materials, 471-472, 397–402. doi: https://doi.org/10.4028/www.scientific.net/kem.471-472.397

- Abbas, B., Renwarin, Y., Bintoro, M. H., Sudarsono, S., Surahman, M., Ehara, H. (2010). Genetic diversity of sago palm in Indonesia based on chloroplast DNA (cpDNA) markers. Biodiversitas Journal of Biological Diversity, 11 (3). doi: https://doi.org/10.13057/biodiv/d110302

- Venkateswar Reddy, M., Amulya, K., Rohit, M. V., Sarma, P. N., Venkata Mohan, S. (2014). Valorization of fatty acid waste for bioplastics production using Bacillus tequilensis: Integration with dark-fermentative hydrogen production process. International Journal of Hydrogen Energy, 39 (14), 7616–7626. doi: https://doi.org/10.1016/j.ijhydene.2013.09.157

- Behera, L., Mohanta, M., Thirugnanam, A. (2022). Intensification of yam-starch based biodegradable bioplastic film with bentonite for food packaging application. Environmental Technology & Innovation, 25, 102180. doi: https://doi.org/10.1016/j.eti.2021.102180

- Patwary, M. A. S., Surid, S. M., Gafur, M. A. (2020). Properties and Applications of Biodegradable Polymers. Journal of Research Updates in Polymer Science, 9, 32–41. doi: https://doi.org/10.6000/1929-5995.2020.09.03

- Lopez-Gil, A., Silva-Bellucci, F., Velasco, D., Ardanuy, M., Rodriguez-Perez, M. A. (2015). Cellular structure and mechanical properties of starch-based foamed blocks reinforced with natural fibers and produced by microwave heating. Industrial Crops and Products, 66, 194–205. doi: https://doi.org/10.1016/j.indcrop.2014.12.025

- Qamruzzaman, Md., Ahmed, F., Mondal, Md. I. H. (2021). An Overview on Starch-Based Sustainable Hydrogels: Potential Applications and Aspects. Journal of Polymers and the Environment, 30 (1), 19–50. doi: https://doi.org/10.1007/s10924-021-02180-9

- Ratnawati, R., Widyastuti, S., Utomo, Y., Evawati, D. (2023). Addition of Anadara Granosa Shell Chitosan in Production Bioplastics. Jurnal Pengelolaan Sumberdaya Alam Dan Lingkungan (Journal of Natural Resources and Environmental Management), 13 (2), 175–185. doi: https://doi.org/10.29244/jpsl.13.2.175-185

- Eby, G. A., Eby, K. L. (2010). Magnesium for treatment-resistant depression: A review and hypothesis. Medical Hypotheses, 74 (4), 649–660. doi: https://doi.org/10.1016/j.mehy.2009.10.051

- Springle, N., Li, B., Soma, T., Shulman, T. (2022). The complex role of single-use compostable bioplastic food packaging and foodservice ware in a circular economy: Findings from a social innovation lab. Sustainable Production and Consumption, 33, 664–673. doi: https://doi.org/10.1016/j.spc.2022.08.006

- Bishop, G., Styles, D., Lens, P. N. L. (2021). Environmental performance of bioplastic packaging on fresh food produce: A consequential life cycle assessment. Journal of Cleaner Production, 317, 128377. doi: https://doi.org/10.1016/j.jclepro.2021.128377

- Burleigh, T. D., Ruhe, C., Forsyth, J. (2003). Photo-Corrosion of Different Metals during Long-Term Exposure to Ultraviolet Light. Corrosion, 59 (9), 774–779. doi: https://doi.org/10.5006/1.3277606

- Havstad, M. R. (2020). Biodegradable plastics. Plastic Waste and Recycling, 97–129. doi: https://doi.org/10.1016/b978-0-12-817880-5.00005-0

- Abang, S., Wong, F., Sarbatly, R., Sariau, J., Baini, R., Besar, N. A. (2023). Bioplastic classifications and innovations in antibacterial, antifungal, and antioxidant applications. Journal of Bioresources and Bioproducts. doi: https://doi.org/10.1016/j.jobab.2023.06.005

- Jones, A., Mandal, A., Sharma, S. (2017). Antibacterial and Drug Elution Performance of Thermoplastic Blends. Journal of Polymers and the Environment, 26 (1), 132–144. doi: https://doi.org/10.1007/s10924-016-0924-y

- Pal, M. K., Lavanya, M. (2022). Microbial Influenced Corrosion: Understanding Bioadhesion and Biofilm Formation. Journal of Bio- and Tribo-Corrosion, 8 (3). doi: https://doi.org/10.1007/s40735-022-00677-x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Budiawan Sulaeman, Nasaruddin Salam, Andi Erwin Eka Putra, Lukmanul Hakim Arma

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.