Identifying some regularities of hydropower components functioning for proper operation of Chameliya hydropower plant in Nepal

DOI:

https://doi.org/10.15587/1729-4061.2023.290012Keywords:

energy, generation, Chameliya hydropower, mechanical, problem, failure, operation, maintenance, thermal, componentAbstract

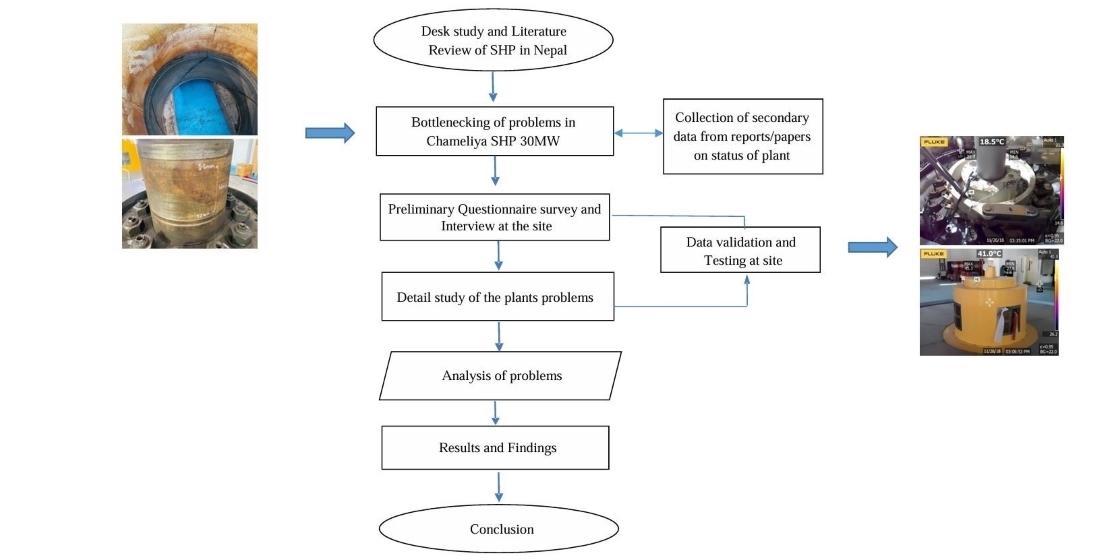

The main objective of the research study is to identify the status and analyze the problems in Chameliya hydropower plants in Nepal. In this paper, the hydropower has been studied to identify some regularities of hydropower components on proper operation and generation through primary and secondary data. Further, it been analyzed by bottlenecking through mechanical components testing for the detail study to find the actual problems. Hydropower contributes about 86 % of total internal generation to available energy in Nepal with 93 % of people having access to electricity through the national grid. Small hydropower plants (less than 30 MW) are 90 % of the installed plants contributing the major electricity demands of nearly 50 % in the country. Though hydropower is one of the major export commodities in the past few years, it still has deficits in the dry season. Chameliya hydropower plant, 30 MW situated in the far-western part of Nepal, generates 670 MWh of energy in the wet season and which declines to 384 MWh in the dry season. Even though the plant does not have the problem of much erosion and has a sufficient flow in the dry season, the generation value is still below the design.

The issue of variation in shaft speed, misalignment of shaft bearing integrity and ultimately friction due to vibration, rises the temperature beyond the limit in the bearing Babbitt material result for failure in the plant with problematic shutdown. Thus, this research primarily focuses on the problem analysis in hydropower plants, concluding with the result that the developing countries need to have more focus on regular preventive maintenance and also schedule large maintenance on mechanical components like shafts, bearings, turbine etc. to avoid bigger damage in the long run. Hence, the study also suggests that mechanical failure in a hydropower is mostly common and therefore, a robust mechanical structure along with high safety factor components need to be encouraged where the possibilities of regular maintenance and smooth operation are reduced.

Supporting Agency

- Authors would like to thank University Grants Commission (UGC), Nepal for providing funds for the fellowship and also Nepal Academy of Science and Technology (NAST) for a laboratory facility for research. Similarly, the authors would also like to thank Chameliya Hydropower Project, NEA for helping in the study with valuable data and survey facilities. We would also like to thank Department of Mechanical and Aerospace Engineering, Pulchowk Campus, IOE for work space and guidance.

References

- World Energy Outlook 2019. IEA. Available at: https://www.iea.org/reports/world-energy-outlook-2019

- Power Plants :: Hydro (More than 1MW). Department of Electricity Development. Available at: http://doed.gov.np/license/54

- Liu, D., Liu, H., Wang, X., Kremere, E. (Eds.) (2019). World Small Hydropower Development Report 2019. United Nations Industrial Development Organization. Available at: https://www.unido.org/sites/default/files/files/2020-02/WSHPDR%202019%20Case%20Studies.pdf

- Bhutto, A. W., Bazmi, A. A., Zahedi, G. (2012). Greener energy: Issues and challenges for Pakistan-hydel power prospective. Renewable and Sustainable Energy Reviews, 16 (5), 2732–2746. doi: https://doi.org/10.1016/j.rser.2012.02.034

- Killingtveit, Å. (2022). Hydropower Resources Assessment—Potential for Further Development. Comprehensive Renewable Energy, 14–29. doi: https://doi.org/10.1016/b978-0-12-819727-1.00069-8

- Gunatilake, H., Wijayatunga, P., Roland-Holst, D. (2020). Hydropower Development and Economic Growth in Nepal. ADB South Asia Working Paper Series. doi: https://doi.org/10.22617/wps200161-2

- Use and Capacity of Global Hydropower. World Watch Institute. Available at: http://www.worldwatch.org/node/9527

- Alam, F., Alam, Q., Reza, S., Khurshid-ul-Alam, S. M., Saleque, K., Chowdhury, H. (2017). A Review of Hydropower Projects in Nepal. Energy Procedia, 110, 581–585. doi: https://doi.org/10.1016/j.egypro.2017.03.188

- Final Report, Evaluation of Small Hydro Power (SHP) Programme of MNRE (2017). Ministry of New & Renewable Energy (MNRE), 90.

- Paish, O. (2002). Small hydro power: technology and current status. Renewable and Sustainable Energy Reviews, 6 (6), 537–556. doi: https://doi.org/10.1016/s1364-0321(02)00006-0

- Ghosh A, M. S. K. A. (2012). Steady growth in small hydropower in India. ICRA rating feature, New Dehli.

- Sapkota, P., Chitrakar, S., Neopane, H. P., Thapa, B. (2022). Problem Identification and Condition Monitoring status of Nepalese Power Plants. IOP Conference Series: Earth and Environmental Science, 1079 (1), 012064. doi: https://doi.org/10.1088/1755-1315/1079/1/012064

- Thapa, S. K., Poudel, L. (2017). Performance Evaluation of Francis Turbine using thermodynamics analysis: A Case Study of Kali Gandaki A Hydropower Plant-144 MW. Proceedings of IOE Graduate Conference.

- Feng, D., Wang, Z., Ma, P., Wang, W. (2013). Analysis and Application of Hydropower Real-time Performance Calculation. Energy and Power Engineering, 05 (04), 63–67. doi: https://doi.org/10.4236/epe.2013.54b012

- Pandey, R., Shrestha, R., Bhattarai, N., Dhakal, R. (2023). Problems identification and performance analysis in small hydropower plants in Nepal. International Journal of Low-Carbon Technologies, 18, 561–569. doi: https://doi.org/10.1093/ijlct/ctad043

- Verma, H., Kumar, A. (2007). Performance Testing and Evaluation of Small Hydropower Plants. International Conference on Small Hydropower. Sri Lanka. Available at: https://www.yumpu.com/en/document/read/33482849/-performance-testing-and-evaluation-of-small-hydropower-ahec

- Zegarac, N. (2017). Improving technical maintenance of systems of mini hydropower plants: Analysis of causes of malfunctions, faults, failures and system failures. Vojnotehnicki Glasnik, 65 (3), 673–702. doi: https://doi.org/10.5937/vojtehg65-13246

- Yaseen, Z. M., Ameen, A. M. S., Aldlemy, M. S., Ali, M., Abdulmohsin Afan, H., Zhu, S. et al. (2020). State-of-the Art-Powerhouse, Dam Structure, and Turbine Operation and Vibrations. Sustainability, 12 (4), 1676. doi: https://doi.org/10.3390/su12041676

- Bashyal, M., Poudel, L. (2021). Performance analysis and rehabilitation prospective of aged Small Hydropower Plant – A Case Study of Fewa Hydropower Plant (1 MW). Proceedings of 10th IOE Graduate Conference. Lalitpur, 161–169.

- Prajapati, R. N., Deo, K., Rauniyar, N., Shrestha, J., Neupane, P. (2017). Identification of Reduction of Power Production in 50 Years Old Panauti Hydropower Plant in Nepal. Journals of Recent Activities in Infrastructure Science, 2 (2). Available at: https://www.researchgate.net/publication/324138661_Identification_of_Reduction_of_Power_Production_in_50_Years_Old_Panauti_Hydropower_Plant_in_Nepal

- Singh, P. (2020). Interview, Performance of Small Hydro Power.

- Mohanta, R. K., Chelliah, T. R., Allamsetty, S., Akula, A., Ghosh, R. (2017). Sources of vibration and their treatment in hydro power stations-A review. Engineering Science and Technology, an International Journal, 20 (2), 637–648. doi: https://doi.org/10.1016/j.jestch.2016.11.004

- Sob, P. (2021). Interview, Performance Analysis of Small Hydro Power.

- Iliev, H. (1999). Failure analysis of hydro-generator thrust bearing. Wear, 225–229, 913–917. doi: https://doi.org/10.1016/s0043-1648(98)00410-4

- NEA, Generation Magzine 14th Issue (2022). Generation Directorate, Nepal Electricity Authority. Available at: https://www.nea.org.np/admin/assets/uploads/annual_publications/Generation_2021-22.pdf

- Stack, J. R., Habetler, T. G., Harley, R. G. (2003). Effects of machine speed on the development and detection of rolling element bearing faults. IEEE Power Electronics Letters, 1 (1), 19–21. doi: https://doi.org/10.1109/lpel.2003.814607

- Hopf, G., Schu¨ler, D. (1989). Investigations on Large Turbine Bearings Working Under Transitional Conditions Between Laminar and Turbulent Flow. Journal of Tribology, 111 (4), 628–634. doi: https://doi.org/10.1115/1.3261987

- Mikula, A. M. (1986). Evaluating Tilting-Pad Thrust Bearing Operating Temperatures. A S L E Transactions, 29 (2), 173–178. doi: https://doi.org/10.1080/05698198608981675

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Roshan Pandey, Rajendra Shrestha, Nawraj Bhattarai

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.