Determining patterns in the formation of an insulation layer of foam coke when protecting concrete against fire by reactive coating

DOI:

https://doi.org/10.15587/1729-4061.2023.293685Keywords:

protective means, structural concrete, thermal destruction of the surface, fire protection of concrete, swelling of the coatingAbstract

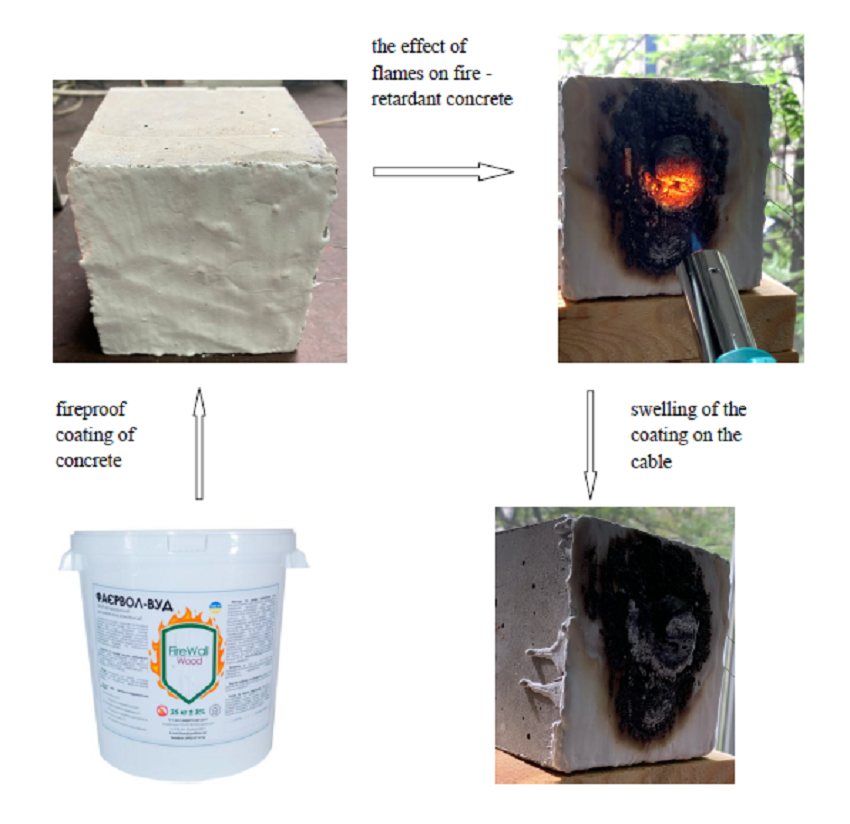

An issue related to using concrete for building structures is to ensure their stability and durability during operation within wide limits. Therefore, the object of research was the change in the properties of concrete in case of fire and its protection when applied with a reactive coating capable of forming a foam coke layer under the influence of high temperature on the coating. It has been proven that in the process of thermal action on the fire-resistant coating, the process of heat insulation of concrete involves the formation of soot-like products on the surface of the material. Thus, under the influence of the flame of the burner, a temperature arose on the surface of the sample, which led to the swelling of the coating by more than 18 mm. The measured temperature on the surface of the concrete sample under the layer of foam coke was no more than 140 °C, which indicates the formation of a fire barrier. In this regard, modeling of the process of heat transfer through the formed layer of foam coke in the process of its protection with a reactive coating was carried out and dependence was established, which makes it possible to estimate the coefficients of temperature conductivity and thermal conductivity during high-temperature action. According to the experimental data and the established dependences, the coefficient of temperature conductivity and heat conductivity of foam coke was calculated, which is 9.17·10–7 m2/s and 0.17 W/(m∙K). The assessment of the maximum possible penetration of fire through the layer of foam coke was carried out. A temperature was formed on the surface of the sample, which significantly exceeded the temperature of the destruction of concrete, and on the surface of concrete under the coating it did not reach 250 °C. So, there are reasons to assert the possibility of targeted regulation of concrete fire protection processes by using reactive coatings capable of forming a protective layer on the surface of the material that inhibits the rate of heat transfer

References

- Moosaei, H. R., Zareei, A. R., Salemi, N. (2022). Elevated Temperature Performance of Concrete Reinforced with Steel, Glass, and Polypropylene Fibers and Fire-proofed with Coating. International Journal of Engineering, 35 (5), 917–930. doi: https://doi.org/10.5829/ije.2022.35.05b.08

- Shen, L., Wang, J., Xu, S., Amoako-Atta, G. (2019). Fire Resistance Behavior of Full-scale Self-thermal Insulation Sandwich Walls Made of Textilereinforced Concrete. International Journal of Heat and Technology, 37 (1), 239–248. doi: https://doi.org/10.18280/ijht.370129

- Ghiji, M., Joseph, P., Guerrieri, M. (2023). Some recent developments and testing strategies relating to the passive fire protection of concrete using intumescent coatings: a review. Journal of Structural Fire Engineering, 14 (1). doi: https://doi.org/10.1108/jsfe-11-2021-0069

- Wang, J., Song, Q.-Y., Han, L.-H. (2023). Temperature field of intumescent coating protected concrete-filled steel tubular columns under fire. Journal of Constructional Steel Research, 201, 107695. doi: https://doi.org/10.1016/j.jcsr.2022.107695

- Zhang, L., Hu, Y., Li, M. (2022). Research on Thermal Response Behavior of the Intumescent Coating at High Temperature: An Experimental and Numerical Study. Buildings, 12 (7), 1014. doi: https://doi.org/10.3390/buildings12071014

- Hou, W., Zhang, G., He, S. (2021). Fire Resistance Tests on Prestressed Concrete Box Girder with Intumescent Fire-Retardant Coatings. Fire Technology, 58 (1), 107–131. doi: https://doi.org/10.1007/s10694-021-01145-7

- Tian, Q., Wang, S., Sui, Y., Lv, Z. (2021). Alkali-activated materials as coatings deposited on various substrates: A review. International Journal of Adhesion and Adhesives, 110, 102934. doi: https://doi.org/10.1016/j.ijadhadh.2021.102934

- Tsapko, Y., Bondarenko, O., Tsapko, A., Sarapin, Y. (2022). Application of Coating for Fire Protection of Textile Structures. Key Engineering Materials, 927, 115–121. doi: https://doi.org/10.4028/p-vd6w4b

- Tsapko, Y., Tsapko, А., Bondarenko, O., Chudovska, V. (2021). Thermophysical characteristics of the formed layer of foam coke when protecting fabric from fire by a formulation based on modified phosphorus-ammonium compounds. Eastern-European Journal of Enterprise Technologies, 3 (10 (111)), 34–41. doi: https://doi.org/10.15587/1729-4061.2021.233479

- Janna, W. S. (2009). Engineering Heat Transfer. CRC Press, 692.

- Potter, M. C. (2018). Engineering analysis. Springer, 434. doi: https://doi.org/10.1007/978-3-319-91683-5

- Cengel, Y. A. (2009). Introduction to Thermodynamics and Heat Transfer. McGraw-Hill, 960.

- Tsapko, Y., Likhnyovskyi, R., Tsapko, А., Kovalenko, V., Slutska, O., Illiuchenko, P. et al. (2023). Determining the thermal-physical characteristics of a coke foam layer in the fire protection of cable articles with foaming coating. Eastern-European Journal of Enterprise Technologies, 2 (10 (122)), 22–30. doi: https://doi.org/10.15587/1729-4061.2023.275550

- Yanke, E., Emde, F., Lesh, F. (1964). Spetsial'nye funktsii (formuly, grafiki, tablitsy). Moscow: Nauka, 344.

- DSTU B V.2.6-189:2013. Metody vyboru teploizoliatsiynoho materialu dlia uteplennia budivel. Kyiv.

- Kryzhanovskiy, Yu. V., Kryzhanovskiy, V. N. (2012). Struktura i raschet gazovogo fakela. Kyiv: «Osvita Ukrainy», 96. Available at: https://ela.kpi.ua/bitstream/123456789/2264/1/Kryzhanovskie_gazovyi_fakel.pdf

- Kalafat, K., Taran, N., Plavan, V., Bessarabov, V., Zagoriy, G., Vakhitova, L. (2020). Comparison of fire resistance of polymers in intumescent coatings for steel structures. Eastern-European Journal of Enterprise Technologies, 4 (10 (106)), 45–54. doi: https://doi.org/10.15587/1729-4061.2020.209841

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K., Matviichuk, A. (2022). Establishing regularities of wood protection against water absorption using a polymer shell. Eastern-European Journal of Enterprise Technologies, 1 (10 (115)), 48–54. doi: https://doi.org/10.15587/1729-4061.2022.252176

- Tsapko, Y., Lomaha, V., Vasylyshyn, R., Melnyk, O., Balanyuk, V., Tsapko, А. et al. (2022). Establishing regularities in the reduction of flammable properties of wood protected with two-component intumescent varnish. Eastern-European Journal of Enterprise Technologies, 3 (10 (117)), 63–71. doi: https://doi.org/10.15587/1729-4061.2022.259582

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuriy Tsapko, Ruslan Likhnyovskyi, Аleksii Tsapko, Kseniia Bielikova, Serhii Poteriaiko, Pavlo Illiuchenko, Olga Bondarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.