Welding room development for simultaneous improvement of welder health and weld quality of gas metals arc welded aluminum AA5083-H112

DOI:

https://doi.org/10.15587/1729-4061.2024.296784Keywords:

gas metal arc welding, AA5083, welding environment, fume exposure, tensile strength, impact energyAbstract

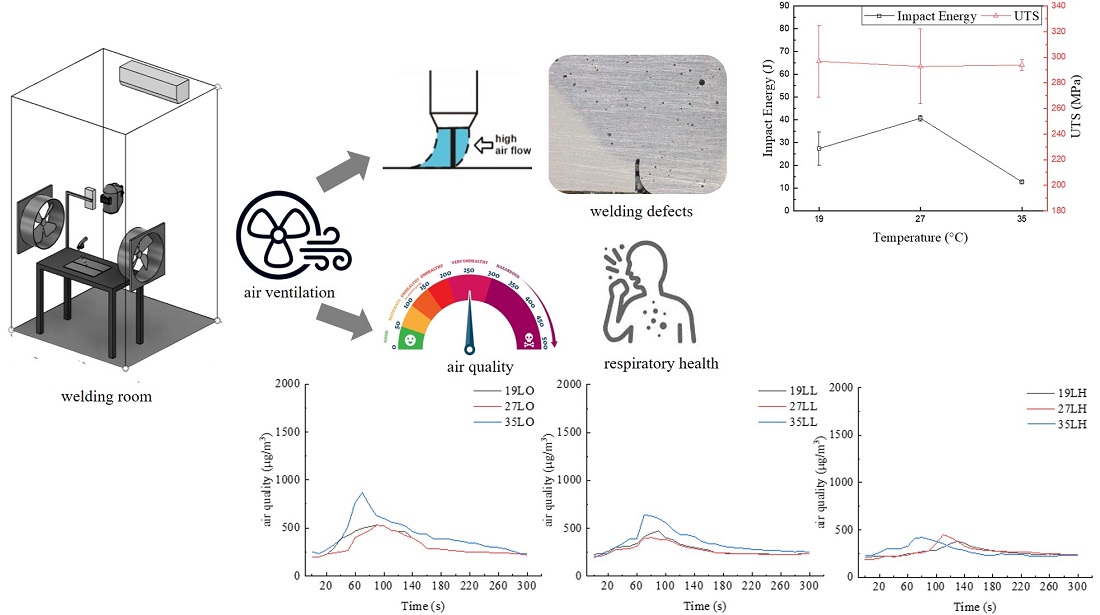

This study investigated the weld joint mechanical properties and welding fume exposure associated with Gas Metal Arc Welding of aluminum AA5083-H112 in 27 different welding room environment conditions. These conditions consist of variation in temperature, as well as intake and exhaust wind velocities. The temperature varies as 19 °C, 27 °C and 35 °C. Both the intake and exhaust velocity vary as 0 m/s, 3.1 m/s and 5.5 m/s. The experimental findings underscore the pronounced influence of these factors on both weld quality and welder exposure to fumes. Notably, intake wind velocity emerges as the most critical factor, contributing significantly to 47.68 % in weld joint tensile strength. The temperature emerges as the least critical factor with 12.02 % of contribution. However, temperature became the most critical factor on weld joint impact energy with 54.89 % of contribution while exhaust wind velocity became the least with 3.89 %. Air quality monitoring highlights the importance of optimal intake and exhaust fan configuration to effectively reduce fume exposure. All examined welding room environment condition are deemed safe for the welder, as they do not exceed the Treshold Limit Value (TLV), except the condition where the welding room lacks of air circulation in intake and exhaust wind velocity of 0 m/s. The identified optimal welding room condition exerts a temperature of 27 °C, intake and exhaust wind velocity of 0 m/s and 3.1 m/s respectively. This condition not only achieves established weld quality standards but also ensures compliance with fume exposure regulation. This research provides valuable insights for optimizing welding room environment to simultaneously maintain weld quality and safeguard the well-being of welders

References

- Gou, G., Zhang, M., Chen, H., Chen, J., Li, P., Yang, Y. P. (2015). Effect of humidity on porosity, microstructure, and fatigue strength of A7N01S-T5 aluminum alloy welded joints in high-speed trains. Materials & Design, 85, 309–317. https://doi.org/10.1016/j.matdes.2015.06.177

- Wang, C. G., Liu, Y., Wang, X. M., Gou, G. Q., Chen, H. (2014). Effects of Environment Temperatures on the Microstructures and Mechanical Properties for Welding Joints of A5083-H111 Alloy. Advanced Materials Research, 936, 1701–1706. https://doi.org/10.4028/www.scientific.net/amr.936.1701

- Kuk, J.-M., Jang, K.-C., Lee, D.-G., Kim, I.-S. (2004). Effect of shielding gas composition on low temperature toughness of Al5083–O gas metal arc welds. Science and Technology of Welding and Joining, 9 (6), 519–524. https://doi.org/10.1179/136217104225021607

- Sabau, A. S., Viswanathan, S. (2002). Microporosity prediction in aluminum alloy castings. Metallurgical and Materials Transactions B, 33 (2), 243–255. https://doi.org/10.1007/s11663-002-0009-2

- Suzuki, R., Sasakura, S., Yokota, Y., Sato, T., Shigemori, Y., Uenaka, A. et al. (2016). Study of wind-toughness of metal arc welding with reference to multi-pass weld metal quality. Welding International, 31 (1), 17–27. https://doi.org/10.1080/09507116.2016.1223188

- Huang, L., Hua, X., Wu, D., Jiang, Z., Ye, Y. (2019). A study on the metallurgical and mechanical properties of a GMAW-welded Al-Mg alloy with different plate thicknesses. Journal of Manufacturing Processes, 37, 438–445. https://doi.org/10.1016/j.jmapro.2018.12.017

- Jang, K. C., Lee, D. G., Kuk, J. M., Kim, I. S. (2005). Welding and environmental test condition effect in weldability and strength of Al alloy. Journal of Materials Processing Technology, 164–165, 1038–1045. https://doi.org/10.1016/j.jmatprotec.2005.02.193

- Prokic-Cvetkovic, R., Kastelec-Macura, S., Milosavljevic, A., Popovic, O., Burzic, M. (2010). The effect of shielding gas composition on the toughness and crack growth parameters of AlMg4,5Mn weld metals. Journal of Mining and Metallurgy, Section B: Metallurgy, 46 (2), 193–202. https://doi.org/10.2298/jmmb1002193p

- Han, Q., Viswanathan, S. (2002). Hydrogen evolution during directional solidification and its effect on porosity formation in aluminum alloys. Metallurgical and Materials Transactions A, 33 (7), 2067–2072. https://doi.org/10.1007/s11661-002-0038-0

- Flynn, M. R., Susi, P. (2012). Local Exhaust Ventilation for the Control of Welding Fumes in the Construction Industry—A Literature Review. The Annals of Occupational Hygiene, 56 (7), 764–776. https://doi.org/10.1093/annhyg/mes018

- Dueck, M. E., Rafiee, A., Mino, J., Nair, S. G., Kamravaei, S., Pei, L., Quémerais, B. (2021). Welding Fume Exposure and Health Risk Assessment in a Cohort of Apprentice Welders. Annals of Work Exposures and Health, 65 (7), 775–788. https://doi.org/10.1093/annweh/wxab016

- Pourhassan, B., Beigzadeh, Z., Nasirzadeh, N., Karimi, A. (2023). Application of Multiple Occupational Health Risk Assessment Models for Metal Fumes in Welding Process. Biological Trace Element Research, 202 (3), 811–823. https://doi.org/10.1007/s12011-023-03717-w

- Chinakhov, D. A., Vorobyev, A. V., Grigorieva, E. G., Mayorova, E. I. (2015). Study of Wind Velocity Impact upon the Quality of Shielding and upon the Thermal Processes under MAG Welding. Applied Mechanics and Materials, 770, 253–257. https://doi.org/10.4028/www.scientific.net/amm.770.253

- Lee, M.-H., McClellan, W. J., Candela, J., Andrews, D., Biswas, P. (2006). Reduction of nanoparticle exposure to welding aerosols by modification of the ventilation system in a workplace. Journal of Nanoparticle Research, 9 (1), 127–136. https://doi.org/10.1007/s11051-006-9181-7

- Maslak, M., Pazdanowski, M., Stankiewicz, M., Wassilkowska, A., Zajdel, P., Zielina, M. (2023). Impact Fracture Surfaces as the Indicators of Structural Steel Post-Fire Susceptibility to Brittle Cracking. Materials, 16 (8), 3281. https://doi.org/10.3390/ma16083281

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Triyono, Anton Harseno, Nurul Muhayat

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.