Development of a fuzzy logic model for predicting the quality of micro friction stir spot welding (µFSSW) using particle swarm optimization

DOI:

https://doi.org/10.15587/1729-4061.2024.297617Keywords:

magnesium alloy, fuzzy logic system, Mamdani, Gaussian functionAbstract

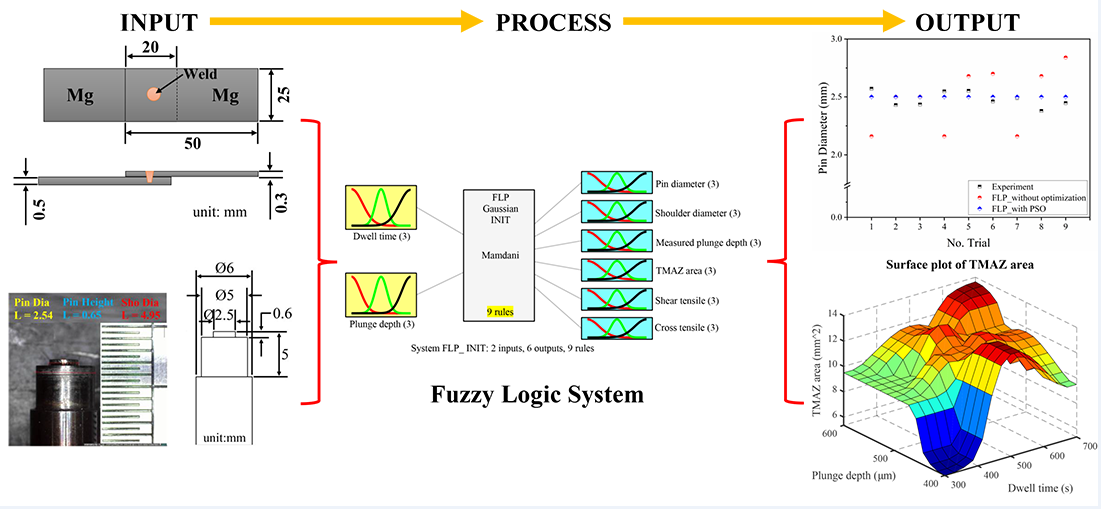

Micro Friction Stir Spot Welding (µFSSW) is crucial in microelectronics and precision manufacturing. It requires a comprehensive understanding of the complex connections between various parameters to achieve the highest quality welds. This study aims to improve the prediction of µFSSW weld quality by incorporating advanced optimization techniques. Fuzzy Logic Optimization is used to model uncertainties, and Particle Swarm Optimization (PSO) is employed to fine-tune parameters for improved accuracy. The fuzzy logic system utilizes Gaussian functions as membership functions, organized with nine rule bases. The results clearly demonstrate that the fuzzy logic model greatly enhances accuracy when combined with Particle Swarm Optimization. The refined model improves precision for pin diameter, shoulder diameter, Thermo-Mechanically Affected Zone (TMAZ) area, and cross-tensile strength. The PSO-optimized model shows lower accuracy in predicting plunge depth and shear tensile strength. The ongoing decline in Root Mean Square Error (RMSE) values highlights the complexity of the results. The optimization significantly improves the model’s ability to predict specific weld quality metrics, as demonstrated by the pin diameter’s reduced RMSE value of 0.07. The collective results showcase an optimized Fuzzy Logic System (FLS) model adept at accurately predicting µFSSW weld quality, demonstrating adaptability across diverse conditions. The discernible increase in accuracy, reaching up to 76 % following the optimization of the fuzzy logic model with PSO, serves as a testament to the efficacy of the employed methodologies in advancing the precision and reliability of µFSSW weld quality predictions

Supporting Agency

- The author expresses gratitude to the Mechanical Engineering Laboratory at Hasanuddin University for their invaluable help with this study. This laboratory's dedicated space and tools have been accommodating in running experiments, gathering data, and analyzing it.

References

- Sen, M., Shankar, S., Chattopadhyaya, S. (2020). Micro-friction stir welding (μFSW) – A review. Materials Today: Proceedings, 27, 2469–2473. https://doi.org/10.1016/j.matpr.2019.09.220

- Balasubramanian, V. (2008). Relationship between base metal properties and friction stir welding process parameters. Materials Science and Engineering: A, 480 (1-2), 397–403. https://doi.org/10.1016/j.msea.2007.07.048

- Singarapu, U., Adepu, K., Arumalle, S. R. (2015). Influence of tool material and rotational speed on mechanical properties of friction stir welded AZ31B magnesium alloy. Journal of Magnesium and Alloys, 3 (4), 335–344. https://doi.org/10.1016/j.jma.2015.10.001

- Ugender, S., Kumar, A., Reddy, A. S. (2014). Microstructure and Mechanical Properties of AZ31B Magnesium Alloy by Friction Stir Welding. Procedia Materials Science, 6, 1600–1609. https://doi.org/10.1016/j.mspro.2014.07.143

- Sevvel, P., Jaiganesh, V. (2014). Improving the Mechanical Properties of Friction Stir Welded AZ31B Magnesium Alloy Flat Plates through Axial Force Investigation. Applied Mechanics and Materials, 591, 11–14. https://doi.org/10.4028/www.scientific.net/amm.591.11

- Badwelan, A., M. Al-Samhan, A., Anwar, S., Hidri, L. (2021). Novel Technique for Enhancing the Strength of Friction Stir Spot Welds through Dynamic Welding Parameters. Metals, 11 (2), 280. https://doi.org/10.3390/met11020280

- Verma, M., Ahmed, S., Saha, P. (2021). Challenges, process requisites/inputs, mechanics and weld performance of dissimilar micro-friction stir welding (dissimilar μFSW): A comprehensive review. Journal of Manufacturing Processes, 68, 249–276. https://doi.org/10.1016/j.jmapro.2021.05.045

- Kumar, S. S., Ashok, S. D. (2014). Development of Acoustic Emission and Motor Current Based Fuzzy Logic Model for Monitoring Weld Strength and Nugget Hardness of FSW Joints. Procedia Engineering, 97, 909–917. https://doi.org/10.1016/j.proeng.2014.12.366

- Senthilkumar, G., Mayavan, T., Manikandan, H. (2022). Prediction of mechanical characteristics of friction welded dissimilar EN 10028P 355 GH steel and AISI 430 steel joint by fuzzy logic analysis. Materials Today: Proceedings, 68, 2182–2188. https://doi.org/10.1016/j.matpr.2022.08.419

- Padmanaban, R., Vignesh, R. V., Povendhan, A. P., Balakumharen, A. P. (2018). Optimizing the tensile strength of friction stir welded dissimilar aluminium alloy joints using particle swarm optimization. Materials Today: Proceedings, 5 (11), 24820–24826. https://doi.org/10.1016/j.matpr.2018.10.280

- Eren, B., Guvenc, M. A., Mistikoglu, S. (2020). Artificial Intelligence Applications for Friction Stir Welding: A Review. Metals and Materials International, 27 (2), 193–219. https://doi.org/10.1007/s12540-020-00854-y

- Membala, S. B., Sutresman, O. S., Arsyad, H., Syahid, M., Widyianto, A. (2022). Indentifying the effect of micro friction stir spot welding (µFSSW) parameters on weld geometry, mechanical properties, and metallography on dissimilar materials of AZ31B and AA1100 . Eastern-European Journal of Enterprise Technologies, 4 (12 (118), 13–21. https://doi.org/10.15587/1729-4061.2022.263350

- Karuthapandi, S., Ramu, M., Thyla, P. R. (2017). Effects of the use of a flat wire electrode in gas metal arc welding and fuzzy logic model for the prediction of weldment shape profile. Journal of Mechanical Science and Technology, 31 (5), 2477–2486. https://doi.org/10.1007/s12206-017-0445-1

- Mystica, A., Senthil kumar, V. S., Sakthi abirami, B. (2022). Analysis and prediction of uncertain responses using regression and fuzzy logic for friction stir welding of AA2014 under n-MQL. Journal of Intelligent & Fuzzy Systems, 43 (3), 2375–2390. https://doi.org/10.3233/jifs-213032

- Baskoro, A. S., Riyanto, A., Arifardi, M. F., Rupajati, P. (2020). Influence of Tools Diameters and Plunge Depth on Mechanical Properties of Micro Friction Stir Spot Welding Materials A1100. IOP Conference Series: Materials Science and Engineering, 727 (1), 012008. https://doi.org/10.1088/1757-899x/727/1/012008

- Shanavas, S., Dhas, J. E. R. (2018). Quality Prediction Of Friction Stir Weld Joints On AA 5052 H32 Aluminium Alloy Using Fuzzy Logic Technique. Materials Today: Proceedings, 5 (5), 12124–12132. https://doi.org/10.1016/j.matpr.2018.02.190

- Hussein, H. K., Shareef, I. R., Zayer, I. A. (2019). Prediction of spot welding parameters using fuzzy logic controlling. Eastern-European Journal of Enterprise Technologies, 5 (2 (101)), 57–64. https://doi.org/10.15587/1729-4061.2019.172642

- Alghannam, E., Lu, H., Ma, M., Cheng, Q., Gonzalez, A. A., Zang, Y., Li, S. (2019). A novel method of using vision system and fuzzy logic for quality estimation of resistance spot welding. Symmetry, 11 (8), 990. https://doi.org/10.3390/sym11080990

- Hynes, N. R. J., Kumar, R., Sujana, J. A. J. (2016). Modeling of process parameters of friction stud welding using fuzzy logic system. International Journal of Advanced Engineering Technology. Available at: https://www.academia.edu/62336555/Modeling_of_Process_Parameters_of_Friction_Stud_Welding_Using_Fuzzy_Logic_System

- Shehabeldeen, T. A., Elaziz, M. A., Elsheikh, A. H., Zhou, J. (2019). Modeling of friction stir welding process using adaptive neuro-fuzzy inference system integrated with harris hawks optimizer. Journal of Materials Research and Technology, 8 (6), 5882–5892. https://doi.org/10.1016/j.jmrt.2019.09.060

- Lashin, M. M. A., Al Samhan, A. M., Badwelan, A., Khan, M. I. (2022). Control of Static and Dynamic Parameters by Fuzzy Controller to Optimize Friction Stir Spot Welding Strength. Coatings, 12 (10), 1442. https://doi.org/10.3390/coatings12101442

- Choudhury, B., Chandrasekaran, M. (2023). Electron Beam Welding Investigation of Inconel 825 and Optimize Energy Consumption Using Integrated Fuzzy Logic-Particle Swarm Optimization Approach. International Journal of Fuzzy Systems, 25 (4), 1377–1399. https://doi.org/10.1007/s40815-022-01431-8

- Mounika, G., Rajyalakshmi, K., Rajkumar, G. V. S., Sravani, D. (2023). Prediction and optimization of process parameters using design of experiments and fuzzy logic. International Journal on Interactive Design and Manufacturing (IJIDeM). https://doi.org/10.1007/s12008-023-01446-x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Hairul Arsyad, Semuel Boron Membala, Agus Widyianto, Muhammad Syahid, Lukmanul Hakim Arma, Rudi, Saiful Mangngenre

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.