Determining conditions for providing maximum traction efficiency of tractor as part of a soil tillage unit

DOI:

https://doi.org/10.15587/1729-4061.2024.297902Keywords:

traction efficiency of the tractor, partial acceleration, combined unit, traction forceAbstract

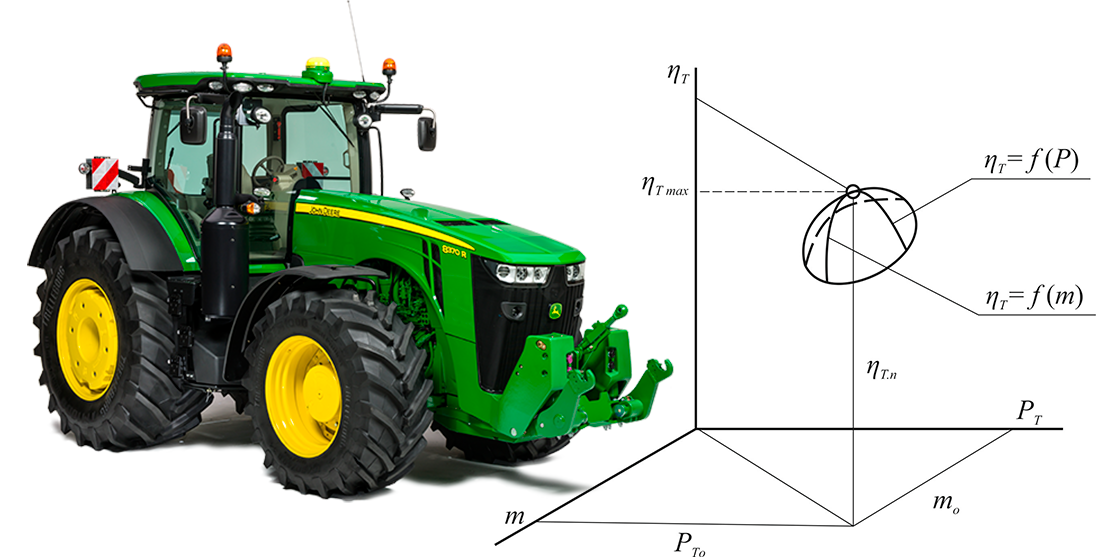

This study aims to investigate the operation of a tractor as part of the tillage unit on the basis of analysis of its interaction with the supporting surface and the correlation between the mass of the tractor and tool. The classic approach to determining the efficiency factor does not take into account the extensive system of power take-off shafts and the extent of their use in combined tillage units. To solve the related problem, a mathematical apparatus was built in the study, which makes it possible to determine the rational ratio between the traction force of a tractor and the mass of the tillage unit.

Underlying the methodological basis of the work is the generalization and analysis of the study of traction indicators of the tractor as part of the tillage unit. Empirical models of unit operation were constructed by employing the basic principles of the system approach and analysis of technical systems. When improving the methodology of research using the method of partial accelerations and our devised procedures, it was possible to significantly reduce the time without compromising the quality of results. The maximum traction efficiency for John Deere 8R series tractors as part of the tillage unit was determined, ηTmax=0.719, as well as the conditions for its provision. The traction efficiency for tractors with wheel formula 4K2, mass Gim=6–10 t, with power consumption from 60 % to 80 % was determined; it is 0.58–0.64. The results of the study make it possible to obtain a new solution to the scientific problem of ensuring the maximum traction efficiency of the tractor as part of the tillage unit, based on the rational ratio between the traction force of the tractor and the weight of the machine-tractor unit. The proposed system approach could be used to justify the layout of units and recommendations regarding their modes of operation in the case of instability of operating mass and traction force

References

- Skyttner, L. (1996). A Selection of Systems Theories. General Systems Theory, 69–131. https://doi.org/10.1007/978-1-349-13532-5_3

- Macmillan, R. H. (2002). The mechanics of tractor-implement performance: theory and worked examples. University of Melbourne, 166. Available at: https://rest.neptune-prod.its.unimelb.edu.au/server/api/core/bitstreams/1fb33cfd-03a2-523e-9958-bfcceebc9ef5/content

- Lebedyev, A. (2021). Modern problems of tractor theory. Tekhnika i tekhnolohiyi APK. 1 (118). 20–25. Available at: https://www.ndipvt.com.ua/TiTAPK/2021/TTAPK20_01_tapk_2021_01.pdf

- Lebedyev, S. (2011). Effective traction efficiency of the tractor at plowing. Tekhnika i tekhnolohiyi APK, 8 (23), 11–14. Available at: https://ndipvt.com.ua/oldsite/arcive_journal/2011/TTAPK%208%202011.pdf

- Rebrov, A. Yu. (2012). Moshchnostnoy balans i KPD pahotnogo MTA pri rabote v tyagovom rezhime. Visnyk NTU «KhPI», 20, 67–73. Available at: https://repository.kpi.kharkov.ua/handle/KhPI-Press/9839

- Antoshchenkov, R., Halych, I., Nykyforov, А., Cherevatenko, H., Chyzhykov, I., Sushko, S. et al. (2022). Determining the influence of geometric parameters of the traction-transportation vehicle’s frame on its tractive capacity and energy indicators. Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 60–67. https://doi.org/10.15587/1729-4061.2022.254688

- Rivero, D., Botta, G. F., Antille, D. L., Ezquerra-Canalejo, A., Bienvenido, F., Ucgul, M. (2022). Tyre Configuration and Axle Load of Front-Wheel Assist and Four-Wheel Drive Tractors Effects on Soil Compaction and Rolling Resistance under No-Tillage. Agriculture, 12 (11), 1961. https://doi.org/10.3390/agriculture12111961

- Md-Tahir, H., Zhang, J., Xia, J., Zhang, C., Zhou, H., Zhu, Y. (2019). Rigid lugged wheel for conventional agricultural wheeled tractors – Optimising traction performance and wheel–soil interaction in field operations. Biosystems Engineering, 188, 14–23. https://doi.org/10.1016/j.biosystemseng.2019.10.001

- Rebrov, O., Kozhushko, A., Kalchenko, B., Mamontov, A., Zakovorotniy, A., Kalinin, E., Holovina, E. (2020). Mathematical model of diesel engine characteristics for determining the performance of traction dynamics of wheel-type tractor. EUREKA: Physics and Engineering, 4, 90–100. https://doi.org/10.21303/2461-4262.2020.001352

- Damanauskas, V., Janulevičius, A. (2015). Differences in tractor performance parameters between single-wheel 4WD and dual-wheel 2WD driving systems. Journal of Terramechanics, 60, 63–73. https://doi.org/10.1016/j.jterra.2015.06.001

- Jensen, T. A., Tullberg, J. N., Antille, D. L. (2022). Improving farm machinery operation and maintenance to optimise fuel use efficiency. Burleigh Dodds Series in Agricultural Science, 71–102. https://doi.org/10.19103/as.2022.0100.03

- Battiato, A., Diserens, E. (2017). Tractor traction performance simulation on differently textured soils and validation: A basic study to make traction and energy requirements accessible to the practice. Soil and Tillage Research, 166, 18–32. https://doi.org/10.1016/j.still.2016.09.005

- CODE 2. OECD Standard code for the official testing of agricultural and forestry tractor performance. Available at: https://www.oecd.org/agriculture/tractors/codes/02-oecd-tractor-codes-code-02.pdf

- Artemov, N. P., Lebedev, A. T., Podrigalo, M. P., Polyanskiy, A. S. et al. (2012). Metod partsial'nyh uskoreniy i ego prilozhenie v dinamike mobil'nyh mashin. Kharkiv: Miskdruk, 220.

- Lebediev, A. T., Lebediev, S. A., Korobko, A. I. (2018). Kvalimetriya ta metrolohichne zabezpechennia vyprobuvan traktoriv. Kharkiv: Vyd-vo «Miskdruk», 394.

- Md-Tahir, H., Zhang, J., Xia, J., Zhou, Y., Zhou, H., Du, J. et al. (2021). Experimental Investigation of Traction Power Transfer Indices of Farm-Tractors for Efficient Energy Utilization in Soil Tillage and Cultivation Operations. Agronomy, 11 (1), 168. https://doi.org/10.3390/agronomy11010168

- Hunt, D., Wilson, D. (2016). Farm Power and Machinery Management. Wiley-Blackwell, 370. Available at: https://redshelf.com/app/ecom/book/1040539/www.waveland.com

- Usaborisut, P., Sukcharoenvipharat, W., Choedkiatphon, S. (2020). Tilling tests of rotary tiller and power harrow after subsoiling. Journal of the Saudi Society of Agricultural Sciences, 19 (6), 391–400. https://doi.org/10.1016/j.jssas.2020.05.002

- Lebedev, A., Shuliak, M., Khalin, S., Lebedev, S., Szwedziak, K., Lejman, K. et al. (2023). Methodology for Assessing Tractor Traction Properties with Instability of Coupling Weight. Agriculture, 13 (5), 977. https://doi.org/10.3390/agriculture13050977

- Système contrôleur de débit GreenStar. John Deere. Available at: https://www.deere.hu/hu/intelligens-gazdalkodasi-megoldasok/helyspecifikus-gazdalkodas/automata-szakaszvezerles-nem-isobus-os-munkagepekhez/.

- Nebraska Tractor Test Laboratory. Institute of Agriculture and Natural Resources. Available at: https://tractortestlab.unl.edu/test-page-nttl

- DLG-Qualitätsprüfungen Technik & Betriebsmittel. Available at: https://www.dlg.org/de/landwirtschaft/tests

- Kalinin, Y., Klets, D., Shuliak, M., Kholodov, A. (2020). Information system for controlling transport-technological unit with variable mass. CEUR Workshop Proceedings, 2732, 303–312. Available at: http://ceur-ws.org/Vol-2732/20200303.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anatoliy Lebedev, Mykhailo Shuliak, Sergei Lebedev, Stanislav Khalin, Tetiana Haidai, Anton Kholodov, Viacheslav Pirogov, Vitalii Shaposhnyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.