Determining the characteristics of contact interaction between the two-row windshield wiper and a curvilinear glass surface

DOI:

https://doi.org/10.15587/1729-4061.2024.298204Keywords:

distributed pressure, plastic deformations, stressed-strained state, damping, hydrodynamics, volume flow rate, turbulenceAbstract

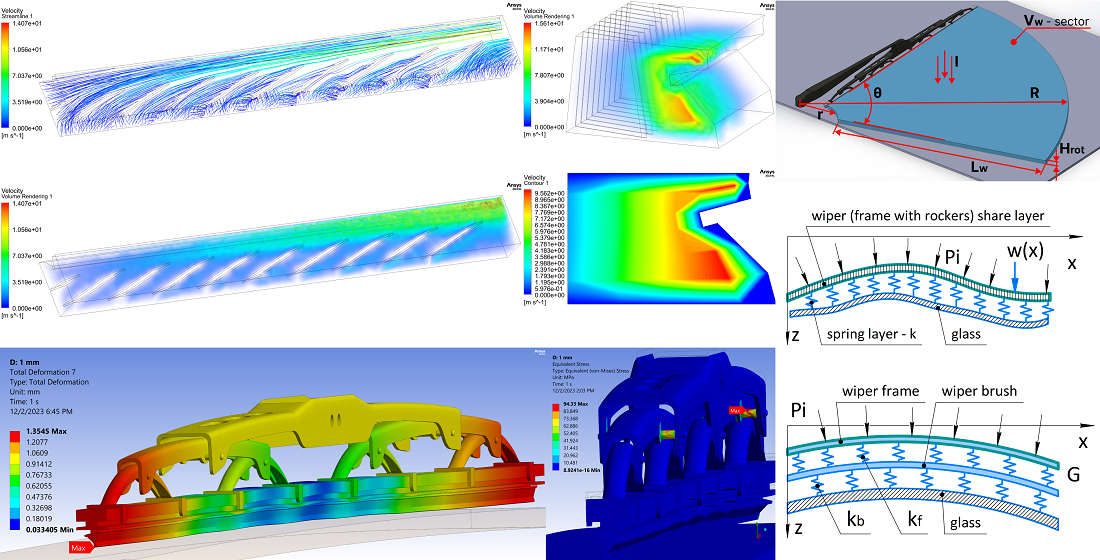

Among the evaluation criteria for determining the efficiency of vehicle windshield cleaning, the pressure distribution of the wiper rubber brush on the glass surface is important. The problem is the lack of this indicator standardization by the United Nations Economic Commission for Europe Rules (UNECE) regarding the windshield wipers certification. The inhomogeneity of the pressure distribution of the conventional wiper (the object of research) is additionally due to the mobility of the links of its mechanism and the plasticity of the rubber brush together with the blade. The pressure value should not be more than 30–50 kPa (33.4 kPa was recorded for the immobilized wiper case), and the external normal load on the frame should be kept within 20...30 N. Under a load of 24 N, the wiper blade was deformed by 1.48 mm (according to R43, it cannot exceed 1.5 mm). Further loading of the wiper frame causes two types of plastic deformation: local and global (loss of the rubber brush shape). Local displacements have increased to 1.82 mm, and the shape of the blade has acquired a "sliced" character, which causes thin jets of dirt. Global ones led to the rubber brush bending with the gap between it and the glass (5.7 mm) and caused the blind zone appearance. Models to mathematically predict layer-by-layer deformations of a conventional wiper were investigated. A model of a double-row blade with separate brushes was built, which enables the parallelization of water flows and explains the increase in the efficiency of its design. Hydrodynamic tests showed 1.58 times greater effectiveness compared to a classic single-row blade: the water flow rate was 15.61 vs 9.86 m/s. This technological advancement is the subject of a patent and a possible working prototype

References

- Kaur, H., Nirmal, U. (2022). A Review on the Development of Wiper System for Automotive Car Windscreen Cleaning Application. Current Journal of Applied Science and Technology, 41 (7), 1–27. https://doi.org/10.9734/cjast/2022/v41i731675

- Jhung, J., Kim, S. (2021). Behind-The-Scenes (BTS): Wiper-Occlusion Canceling for Advanced Driver Assistance Systems in Adverse Rain Environments. Sensors, 21 (23), 8081. https://doi.org/10.3390/s21238081

- Graham, B., Knowles, J., Mavros, G. (2023). The influence of contact distribution shaping on the dynamic response of a wiper blade. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 095440702311647. https://doi.org/10.1177/09544070231164792

- Graham, B., Knowles, J., Mavros, G. (2023). Quantitative Multi-Physics Tools for Automotive Wiper Design. SAE Technical Paper Series. https://doi.org/10.4271/2023-01-0602

- Antonescu, O., Valeanu, D., Antonescu, D., Strimbeanu, M. (2023). Contributions to the Geometric Synthesis of the Windshield Wiper Mechanism with Rocker-Slider Blade. Mechanisms and Machine Science, 404–413. https://doi.org/10.1007/978-3-031-45709-8_40

- Sharveswaran, A., Nirmal, U. (2020). Research Development on Wiper Mechanism in Automotive Application: A Critical Review. Current Journal of Applied Science and Technology, 39 (35), 133–161. https://doi.org/10.9734/cjast/2020/v39i3531064

- Li, Y., Xu, J. (2022). Dynamic characteristics and generation mechanism of windscreen frameless wiper blade oscillations. Nonlinear Dynamics, 111 (4), 3053–3079. https://doi.org/10.1007/s11071-022-08030-0

- Yang, X., Wang, Y., Guo, H., Yuan, T., Zheng, L., Sun, P. (2022). A theoretical analysis of friction and vibration characteristics of wiper reversal process. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 237 (6), 1327–1337. https://doi.org/10.1177/09544070221091021

- Zhao, Z., Yabuno, H., Kamiyama, K. (2022). Dynamic Analysis of a Wiper Blade in Consideration of Attack Angle and Clarification of the Jumping Phenomenon. Applied Sciences, 12 (9), 4112. https://doi.org/10.3390/app12094112

- Salleh, I., Z. Md Zain, M., R. Abu Bakar, A. (2018). Contact Force and Dynamic Behavior of Automobile Wiper Blade System. International Journal of Engineering & Technology, 7 (3.17), 100. https://doi.org/10.14419/ijet.v7i3.17.16630

- Roland, A., Wejin, J., Misra, S., Sharma, M. M., Damaševičius, R., Maskeliūnas, R. (2022). A Dynamic Rain Detecting Car Wiper. Lecture Notes in Networks and Systems, 1375–1383. https://doi.org/10.1007/978-3-030-96308-8_127

- Akanni, J., Ojo, A. O., Abdulwahab, A., Isa, A. A., Ogunbiyi, O. (2022). Development and Implementation of a Prototype Automatic Rain-Sensor Car Wiper System. Journal of Applied Sciences and Environmental Management, 26 (11), 1821–1826. https://doi.org/10.4314/jasem.v26i11.13

- Yadav, S. (2021). Automatic Rain Sensing Wiper using Arduino. International Journal for Research in Applied Science and Engineering Technology, 9 (VI), 5434–5438. https://doi.org/10.22214/ijraset.2021.36065

- Chen, T., Hong, Y. (2020). Mathematical Formulae for the Vibration Frequencies of Rubber Wiper on Windshield. arXiv. https://doi.org/10.48550/arXiv.2003.06022

- Yunpeng, L., Jingjing, X., Xin, W. (2021). Shape analysis and numerical fitting of boneless wiper reed. Journal of Physics: Conference Series, 1939 (1), 012049. https://doi.org/10.1088/1742-6596/1939/1/012049

- Huang, T. C., Tsai, J. W., Liao, K. C. (2021). Geometry Optimization of a Metallic Flexor for Flat Wipers. International Journal of Automotive Technology, 22 (3), 823–830. https://doi.org/10.1007/s12239-021-0075-6

- Holenko, K., Voichyshyn, Y., Svidersky, V., Klypko, O. (2023). Simulation of wiper behavior during contact with a curved surface, factors affecting driving safety. Advances in mechanical engineering and transport, 1 (20), 127–137. https://doi.org/10.36910/automash.v1i20.1041

- Shirsikar, A., Khatik, P., Singh, K., Ram, L. (2022). Optimized Wiper Design using Computational Fluid Dynamics. ARAI Journal of Mobility Technology, 2 (4), 401–410. https://doi.org/10.37285/ajmt.2.4.8

- Yan, J., Zhu, K., Huang, X., Chen, K. (2022). Design Modification of Vehicle Body Structure for Wiper System Waterproof Performance. Proceedings of China SAE Congress 2021: Selected Papers, 1093–1102. https://doi.org/10.1007/978-981-19-3842-9_85

- Dykha, A., Makovkin, O. (2019). Physical basis of contact mechanics of surfaces. Journal of Physics: Conference Series, 1172, 012003. https://doi.org/10.1088/1742-6596/1172/1/012003

- Chen, Z., Gu, Z., Jiang, T. (2019). Research on transient aerodynamic characteristics of windshield wipers of vehicles. International Journal of Numerical Methods for Heat & Fluid Flow, 29 (8), 2870–2884. https://doi.org/10.1108/hff-09-2018-0531

- Marchenko, D., Dykha, A., Aulin, V., Matvyeyeva, K., Tishechkina, K., Kurepin, V. (2020). Development of Technology and Research of Method of Electric Hydropulse Hardening of Machine Parts. 2020 IEEE Problems of Automated Electrodrive. Theory and Practice (PAEP). https://doi.org/10.1109/paep49887.2020.9240796

- Cadirci, S., Ak, E. S., Selenbas, B., Gunes, H. (2017). Numerical and Experimental Investigation of Wiper System Performance at High Speeds. Journal of Applied Fluid Mechanics, 10 (3), 861–870. https://doi.org/10.18869/acadpub.jafm.73.240.26527

- Holenko, K., Koda, E., Kernytskyy, I., Babak, O., Horbay, O., Popovych, V. et al. (2023). Evaluation of Accelerator Pedal Strength under Critical Loads Using the Finite Element Method. Applied Sciences, 13 (11), 6684. https://doi.org/10.3390/app13116684

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Kostyantyn Holenko, Aleksandr Dykha, Yurii Voichyshyn, Orest Horbay, Maksym Dykha, Volodymyr Dytyniuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.