Information technologies in the management of technological processes for the production of building products

DOI:

https://doi.org/10.15587/1729-4061.2024.298480Keywords:

information technology, automation of process control, wind turbine blades, production of construction productsAbstract

The object of the study is the production of construction products with fillers from recycled wind turbine blades.

The study solves the problem related to the possibility of using fillers from recycled wind turbine blades in the technological process of manufacturing construction products.

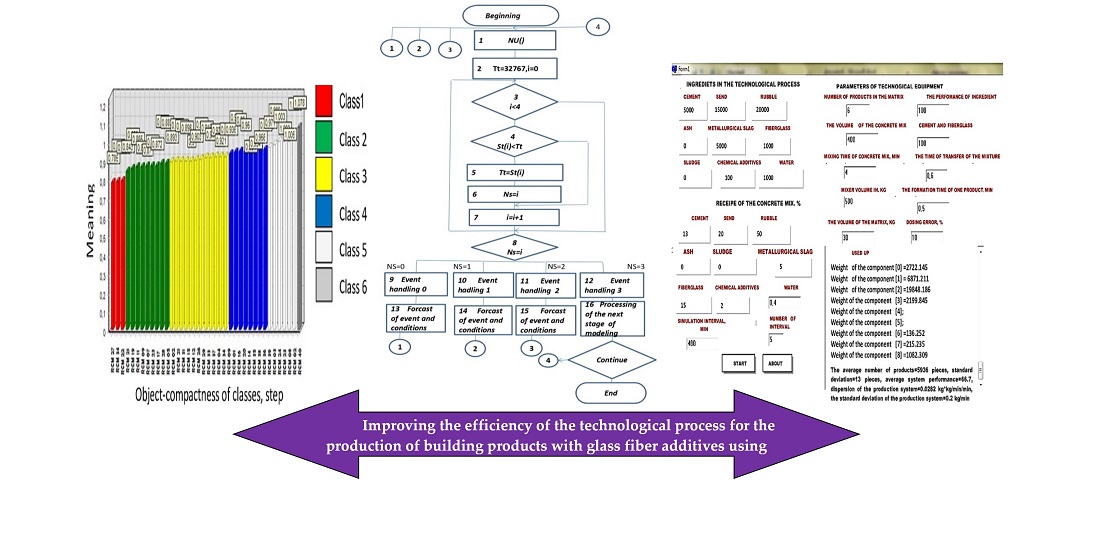

According to the results of the study, concrete mixtures with the most optimal formulations that meet the requirements of state standards were classified, this was achieved due to effective indicators reflecting the characteristics of concrete mixtures.

The developed algorithm of the technological process of production of building products was used in the development of the program code, this became possible due to the consideration of assumptions and limitations of the technological equipment used in production.

The program for managing the technological process of manufacturing construction products is developed in C++, which does not require additional resources for auxiliary operations, has the ability to metaprogram and has the necessary performance. The adequacy of the model is ensured by the maximum approximation to real production.

The effectiveness of research results in real production is explained by high-quality mixtures, dosage of ingredients, optimal parameters of technological equipment, process control based on data obtained by modeling, which reduces the number of defects and increases equipment productivity.

The conditions for using the results of the study are the legislation of the country related to environmental requirements, as well as compliance with the technological process.

For the resulting construction products, the bending strength increased by 20 % compared to traditional ones, the number of defects does not exceed 15 %, and equipment productivity increased by 12 %

References

- Carbon Recycling. Available at: https://www.erdwich.com/en/erdwich-info-centre/read-all-about-it/news-detail/en-carbon-recycling/

- Krauklis, A. E., Karl, C. W., Gagani, A. I., Jørgensen, J. K. (2021). Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. Journal of Composites Science, 5 (1), 28. https://doi.org/10.3390/jcs5010028

- Amaechi, C. V., Agbomerie, C. O., Orok, E. O., Ye, J. (2020). Economic Aspects of Fiber Reinforced Polymer Composite Recycling. Encyclopedia of Renewable and Sustainable Materials, 377–397. https://doi.org/10.1016/b978-0-12-803581-8.10738-6

- Accelerating Wind Turbine Blade Circularity (2020). WindEurope. Available at: https://windeurope.org/wp-content/uploads/files/about-wind/reports/WindEurope-Accelerating-wind-turbine-blade-circularity.pdf

- Technologies for recycling polymer composite materials. Current state and development for the 2020s. Available at: https://compositeworld.ru/articles/tech/id61c2dcfb8606de0019d92093

- Askar, M. K., Askar, L. K., Al-Kamaki, Y. S. S., Ferhadi, R. (2023). Effects of chopped CFRP fiber on mechanical properties of concrete. Heliyon, 9 (3), e13832. https://doi.org/10.1016/j.heliyon.2023.e13832

- Ahmed, H. U., Faraj, R. H., Hilal, N., Mohammed, A. A., Sherwani, A. F. H. (2021). Use of recycled fibers in concrete composites: A systematic comprehensive review. Composites Part B: Engineering, 215, 108769. https://doi.org/10.1016/j.compositesb.2021.108769

- Yazdanbakhsh, A., Bank, L. C., Rieder, K.-A., Tian, Y., Chen, C. (2018). Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resources, Conservation and Recycling, 128, 11–21. https://doi.org/10.1016/j.resconrec.2017.08.005

- Pławecka, K., Przybyła, J., Korniejenko, K., Lin, W.-T., Cheng, A., Łach, M. (2021). Recycling of Mechanically Ground Wind Turbine Blades as Filler in Geopolymer Composite. Materials, 14 (21), 6539. https://doi.org/10.3390/ma14216539

- Nagle, A. J., Delaney, E. L., Bank, L. C., Leahy, P. G. (2020). A Comparative Life Cycle Assessment between landfilling and Co-Processing of waste from decommissioned Irish wind turbine blades. Journal of Cleaner Production, 277, 123321. https://doi.org/10.1016/j.jclepro.2020.123321

- Yildiz, N., Hemida, H., Baniotopoulos, C. (2022). Maintenance and End-of-Life Analysis in LCA for Barge-Type Floating Wind Turbine. Wind, 2 (2), 246–259. https://doi.org/10.3390/wind2020014

- Revilla-Cuesta, V., Manso-Morato, J., Hurtado-Alonso, N., Skaf, M., Ortega-López, V. (2024). Mechanical and environmental advantages of the revaluation of raw-crushed wind-turbine blades as a concrete component. Journal of Building Engineering, 82, 108383. https://doi.org/10.1016/j.jobe.2023.108383

- T Muthukumarana, T. V., Arachchi, M. A. V. H. M., Somarathna, H. M. C. C., Raman, S. N. (2023). A review on the variation of mechanical properties of carbon fibre-reinforced concrete. Construction and Building Materials, 366, 130173. https://doi.org/10.1016/j.conbuildmat.2022.130173

- Recycling wind turbine blades. Available at: https://www.betonconsultingeng.com/recycling-wind-turbine-blades/

- State Industry Standard 25192-2012. Concrete classification and general technical requirements. Introduction. 2021-03-01. Available at: https://kbexpert.kz/wp-content/uploads/2021/07/%D0%93%D0%9E%D0%A1%D0%A2-25192-2012-%D0%91%D0%B5%D1%82%D0%BE%D0%BD%D1%8B.-%D0%9A%D0%BB%D0%B0%D1%81%D1%81%D0%B8%D1%84%D0%B8%D0%BA%D0%B0%D1%86%D0%B8%D1%8F-%D0%B8-%D0%BE%D0%B1%D1%89%D0%B8%D0%B5-%D1%82%D0%B5%D1%85%D0%BD%D0%B8%D1%87%D0%B5%D1%81%D0%BA%D0%B8%D0%B5-%D1%82%D1%80%D0%B5%D0%B1%D0%BE%D0%B2%D0%B0%D0%BD%D0%B8%D1%8F.pdf

- State Industry Standard 10180-2012. Concrete. Methods for determining strength from control samples. Introduction. Available at: https://files.stroyinf.ru/Data2/1/4293782/4293782275.pdf

- State Industry Standard 10060-2012. Concretes. Methods for determination of frost-resistance. Available at: https://online.zakon.kz/Document/?doc_id=31521910&pos=3;-102#pos=3;-102

- State Industry Standard 12730.3-2020. Concrete. Methods for determining water absorption. Available at: https://meganorm.ru/Index/74/74489.htm

- Akishev, K., Bykov, P., Shoshay, Zh., Tulegulov, A., Yergaliyev, D. (2022). Mathematical formulation and the problem solution clustering recipes of concrete mixtures using technogenic waste and slags of metallurgical enterprises. Метаllurjia, 61 (1), 213–216. Available at: https://hrcak.srce.hr/file/381641

- Akishev, K. M. (2019). Computer program "Simulation model of a technological line for the production of construction products using industrial waste". Certificate of entry of information into the state register of rights to objects protected by copyright. No. 6653.

- Sobchak, A., Shostak, E., Tseplyaeva, T., Popova, O., Firsova, A. (2016). Designing an approach to building the teams of high technological projects performers at virtual instrument-making enterprises. Eastern-European Journal of Enterprise Technologies, 3 (2 (81)), 47–54. https://doi.org/10.15587/1729-4061.2016.71493

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Akishev Karshyga, Aryngazin Kapar, Ospanov Erbol, Tulegulov Amandos, Nurtai Zhadira, Yergaliyev Dastan, Ussenkulova Sholpan, Ussenlulov Zhenisbek

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.