Identifying the influence of design parameters of single-chamber hydrostatic bearing of fuel pump on its main characteristics

DOI:

https://doi.org/10.15587/1729-4061.2024.298646Keywords:

single-chamber bearing, nozzle diameter, chamber width, load-bearing capacity, lubricant consumptionAbstract

The object of this study is hydrostatic processes in the fluid friction bearings of gear-type aviation fuel pumps.

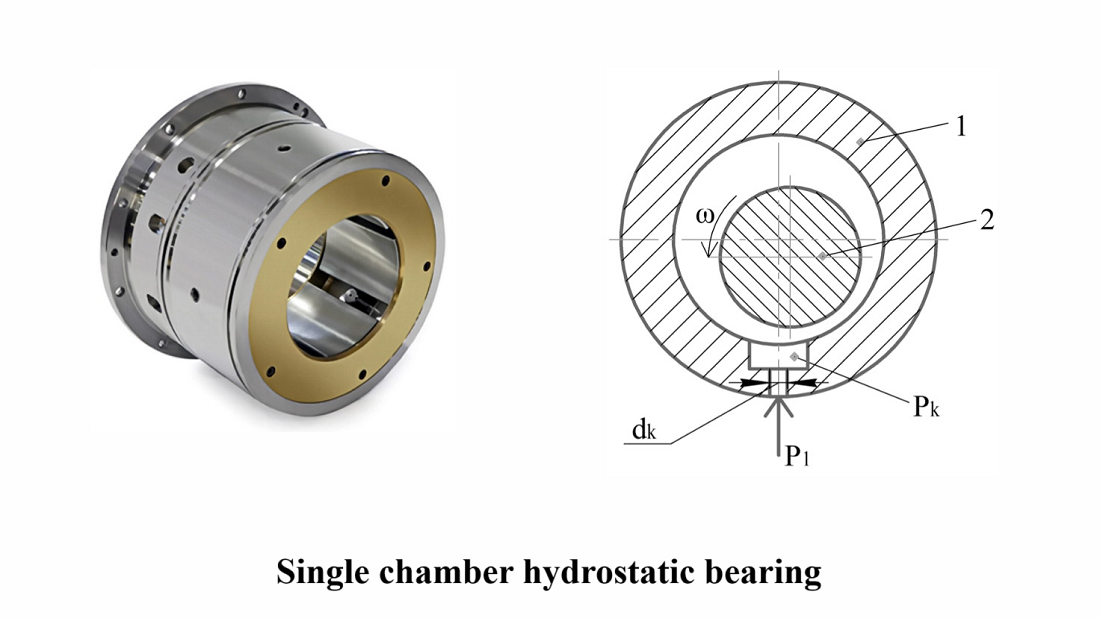

The problem of the influence of the design parameters of a single-chamber hydrostatic bearing on its main characteristics was solved. The main characteristics were considered to be the load-bearing capacity and the flow rate of the working fluid. When determining the main characteristics of a single-chamber hydrostatic bearing, the Reynolds and flow balance equations were solved jointly. The resulting diagram of pressure distribution over the working surface of the bearing was used to determine the main characteristics.

The influence of the clearance, nozzle diameter, and chamber width on the load-bearing capacity and working fluid flow of a single-chamber hydrostatic bearing was studied.

It has been established that as the gap increases, the load-bearing capacity of a single-chamber bearing decreases, and the flow rate of the working fluid increases. As the nozzle diameter increases, the bearing's load-bearing capacity increases. Increasing the width of the chambers leads to an increase in the load-bearing capacity and flow of working fluid through the bearing. When the gap increases from 0.0125 mm to 0.0425 mm, the bearing capacity decreases by 1.156 times. The flow rate of working fluid through the bearing increases by 1.4 times. With an increase in the nozzle diameter from 1.5 mm to 3 mm, the bearing capacity increases slightly by approximately 1.02 times. Increasing the width of the chambers from 4 mm to 8 mm increases the load-bearing capacity by 1.29 times and increases the flow rate of working fluid by 1.4 times.

The results show that a single-chamber hydrostatic bearing can provide the required load-bearing capacity by selecting design parameters. The given mathematical dependences could be used for practical calculations of single-chamber hydrostatic bearings

References

- Xie, Z., Jiao, J,. Yang, K. (2023). Study on the Lubrication and Anti-eccentric Load Characteristics of the Aero Gear Pump Bearing. Journal of Mechanical Engineering, Chinese Mechanical Engineering Society, 59 (9), 198–211.

- Wei, S., Wang, J., Cui, J., Song, S., Li, H., Fu, J. (2022). Online monitoring of oil film thickness of journal bearing in aviation fuel gear pump. Measurement, 204, 112050. https://doi.org/10.1016/j.measurement.2022.112050

- Gao, N., Li, H., Hong, L., Cao, R., Fu, J. (2022). Reliability analysis of journal bearings inside aero-gear pump based on AK-IS method. Journal of Beijing University of Aeronautics and Astronautics, 48 (6), 1057–1064. Available at: https://bhxb.buaa.edu.cn/bhzk/en/article/doi/10.13700/j.bh.1001-5965.2020.0713

- Tacconi, J., Shahpar, S., King, A., Olufeagba, J. P., Khan, R., Sant, I., Yates, M. (2021). Elasto-Hydrodynamic Model of Hybrid Journal Bearings for Aero-Engine Gear Fuel Pump Applications. Journal of Tribology, 144 (3), 031604. https://doi.org/10.1115/1.4052479

- Torrent, M., Gamez-Montero, P. J., Codina, E. (2021). Model of the Floating Bearing Bushing Movement in an External Gear Pump and the Relation to Its Parameterization. Energies, 14 (24), 8553. https://doi.org/10.3390/en14248553

- Zhu, J., Li, H., Wei, S., Fu, J., Xu, X. (2021). An approach of simulating journal bearings-gear pump system including components’ cavitation. Simulation Modelling Practice and Theory, 108, 102236. https://doi.org/10.1016/j.simpat.2020.102236

- Zhu, J., Li, H., Fu, J., Liu, X., Wang, S. (2020). Numerical analysis on the start behavior of rough journal bearings during the gear pump meshing cycle. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 234 (8), 1275–1295. https://doi.org/10.1177/1350650120908116

- Zhu, J.-X., Li, H.-C., Fu, J.-F., Wei, S.-J., Liu, X.-W. (2020). Research on Aero-Gear Pump Journal Bearings Start-Up Transient Lubrication Characteristics with Radial Micro-Motion Analysis Coupled CFD. Journal of Propulsion Technology, 7, 1601–1611. https://doi.org/10.13675/j.cnki.tjjs.190462

- Zhou, Y., Ci, Y. (2019). Temperature rise of journal bearing of the high-speed circular arc gear pump. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234 (8), 1492–1499. https://doi.org/10.1177/0954406219896818

- Zhu, J.-X., Li, H.-C., Fu, J.-F., Liu, X.-W. (2020). Numerical Analysis of Non-Linear Transient Characteristics of Aviation Fuel Gear Pump Sliding Bearings. Journal of Propulsion Technology, 2, 412–422. https://doi.org/10.13675/j.cnki.tjjs.190004

- Zhu, J., Li, H., Fu, J., Liu, X. (2020). Lubrication characteris in contact state of journal bearings inside aero gear pump. Journal of Aerospace Power, 35 (1), 169–174.

- Zhang, G., Liang, M., Guo, J., Niu, X. (2022). Dynamic characteristics of misaligned gear coupling-bearing-rotor system. Journal of Aerospace Power, 2, 225–234. https://doi.org/10.13224/j.cnki.jasp.20210017

- Nazin, V. (2023). Identifying the influence of design parameters of a hydrostatic bearing in an aircraft fuel pump on its static characteristics. Eastern-European Journal of Enterprise Technologies, 5 (1 (125)), 28–34. https://doi.org/10.15587/1729-4061.2023.289426

- Nazin, V. (2023). Revealing the influence of structural and operational parameters of a hydrostatic bearing in a gear-type fuel pump on its main characteristics. Eastern-European Journal of Enterprise Technologies, 2 (1 (122)), 92–98. https://doi.org/10.15587/1729-4061.2023.277755

- Emtsev, B. T. (1978). Tehnicheskaya gidromehanika. Moscow: Mashinostroenie, 463.

- Bogdanov, O. I., D'yachenko, S. K. (1966). Raschet opor skol'zheniya. Kyiv: Tehnika, 242.

- Tipey, N., Konstantinesku, V. N., Nika, A., Bitse, O. (1964). Podshipniki skol'zheniya: Raschet, proektirovanie, smazka. Buharest: Izdatel'stvo Akad. Rum. Nar. Resp., 457.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vladimir Nazin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.