Development of technology for the production of all-purpose buckwheat malt using plasmochemically activated aqueous solutions

DOI:

https://doi.org/10.15587/1729-4061.2024.298797Keywords:

buckwheat malt, plasma chemical activation, aqueous solutions, hydrogen peroxide, amino acidsAbstract

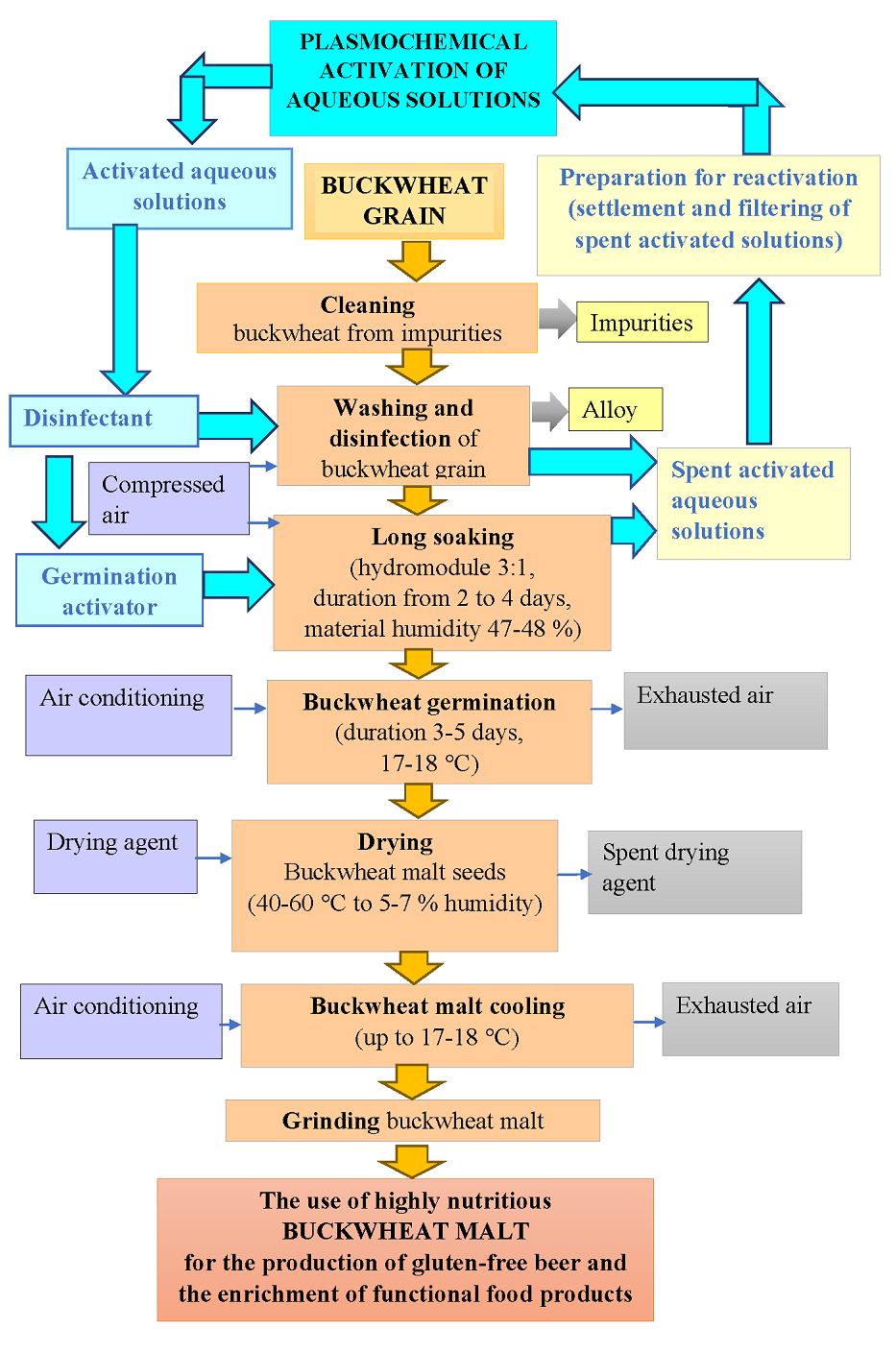

The result of the conducted research is the development of buckwheat malt production technology using plasma-chemically activated aqueous solutions. Buckwheat grain with high starch content became the object of research. The main technological problem is obtaining high-quality brewing malt suitable for the production of gluten-free beer. The expediency of using plasma-chemically activated aqueous solutions as an intensifier of the process of germination of buckwheat grains and an effective disinfectant of buckwheat malt has been experimentally proven. It is shown that the use of plasma chemical activation of technological solutions allows to speed up the process of moistening of buckwheat grain by more than 2 times. The energy and germination capacity of buckwheat grains, when using plasma-chemically activated aqueous solutions, underwent positive changes. The effect of increasing the energy of germination was from 8 to 14 %, and the ability to germinate was 2–9 %. The amylolytic activity of buckwheat malt was analyzed, an increase in amylolytic activity in the range of 30–77 units/g was noted. The extractability of buckwheat malt was investigated separately. This indicator increased by 2–9 % depending on the concentration of peroxides in the solution. The Kolbach index also increased by 2–10 %, which indicates an intensive course of proteolysis. The total amount of amino acids in the experimental samples increased by 619 mg/100 g. There was a significant decrease in the viscosity of the wort, which indicates the high solubility of the obtained buckwheat malt.

The technology can be applied in the industrial production of brewing malt and sprouted buckwheat grain of functional purpose. The developed buckwheat malting technology will receive priority in the production of environmentally friendly buckwheat malts of universal purpose that are not contaminated with pathogenic microflora

References

- Kim, S. J., Sohn, H. B., Suh, J. T., Kim, G. H., Hong, S. Y., Chang, D. C. et al. (2017). Domestic and Overseas Status of Buckwheat Production and Future Trends. Journal of the Korean Society of International Agricultue, 29(3), 226–233. https://doi.org/10.12719/ksia.2017.29.3.226

- Lu, L., Murphy, K., Baik, B. (2013). Genotypic Variation in Nutritional Composition of Buckwheat Groats and Husks. Cereal Chemistry, 90 (2), 132–137. https://doi.org/10.1094/cchem-07-12-0090-r

- Ikeda, K. (2002). Buckwheat composition, chemistry, and processing. Advances in Food and Nutrition Research, 395–434. https://doi.org/10.1016/s1043-4526(02)44008-9

- Giménez-Bastida, J., Piskuła, M., Zieliński, H. (2015). Recent Advances in Processing and Development of Buckwheat Derived Bakery and Non-Bakery Products – a Review. Polish Journal of Food and Nutrition Sciences, 65 (1), 9–20. https://doi.org/10.1515/pjfns-2015-0005

- Vasylieva, N., Vinichenko, I., Katan, L. (2015). Economic and mathematical evaluation of Ukrainian agrarian market by branches. Econimic Annals – XXI, 9-10, 41–44. Available at: http://nbuv.gov.ua/UJRN/ecchado_2015_9-10_10

- Borgonovi, S. M., Chiarello, E., Pasini, F., Picone, G., Marzocchi, S., Capozzi, F. et al. (2023). Effect of Sprouting on Biomolecular and Antioxidant Features of Common Buckwheat (Fagopyrum esculentum). Foods, 12 (10), 2047. https://doi.org/10.3390/foods12102047

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. https://doi.org/10.15587/1729-4061.2020.200026

- Zhygynov, D. A., Soc, S. M., Drozdov, A. Y. (2016). Production and quality of buckwheat products. Grain Products and Mixed Fodder’s, 64 (4), 22–25. https://doi.org/10.15673/gpmf.v64i4.263

- Sturza, A., Păucean, A., Chiș, M. S., Mureșan, V., Vodnar, D. C., Man, S. M. et al. (2020). Influence of Buckwheat and Buckwheat Sprouts Flours on the Nutritional and Textural Parameters of Wheat Buns. Applied Sciences, 10 (22), 7969. https://doi.org/10.3390/app10227969

- Brajdes, C., Vizireanu, C. (2012). Sprouted buckwheat an important vegetable source of antioxidants. The Annals of the University Dunarea de Jos of Galati. Fascicle VI-Food Technology, 36 (1), 53–60.

- Zhao, X., Li, C., Jiang, Y., Wang, M., Wang, B., Xiao, L. et al. (2020). Metabolite fingerprinting of buckwheat in the malting process. Journal of Food Measurement and Characterization, 15 (2), 1475–1486. https://doi.org/10.1007/s11694-020-00737-1

- Xu, F., Gao, Q., Ma, Y., Guo, X., Wang, M. (2014). Comparison of Tartary Buckwheat Flour and Sprouts Steamed Bread in Quality and Antioxidant Property. Journal of Food Quality, 37 (5), 318–328. https://doi.org/10.1111/jfq.12101

- Giovanelli, G., Bresciani, A., Benedetti, S., Chiodaroli, G., Ratti, S., Buratti, S., Marti, A. (2023). Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses. Foods, 12 (19), 3578. https://doi.org/10.3390/foods12193578

- Kumari, S., Singh, B., Kaur, A. (2023). Influence of malted buckwheat, foxtail and proso millet flour incorporation on the physicochemical, protein digestibility and antioxidant properties of gluten-free rice cookies. Food Chemistry Advances, 3, 100557. https://doi.org/10.1016/j.focha.2023.100557

- Molinari, R., Costantini, L., Timperio, A. M., Lelli, V., Bonafaccia, F., Bonafaccia, G., Merendino, N. (2018). Tartary buckwheat malt as ingredient of gluten-free cookies. Journal of Cereal Science, 80, 37–43. https://doi.org/10.1016/j.jcs.2017.11.011

- Ispiryan, L., Kuktaite, R., Zannini, E., Arendt, E. K. (2021). Fundamental study on changes in the FODMAP profile of cereals, pseudo-cereals, and pulses during the malting process. Food Chemistry, 343, 128549. https://doi.org/10.1016/j.foodchem.2020.128549

- Yang, D., Gao, X. (2020). Progress of the use of alternatives to malt in the production of gluten-free beer. Critical Reviews in Food Science and Nutrition, 62 (10), 2820–2835. https://doi.org/10.1080/10408398.2020.1859458

- Rubio-Flores, M., Serna-Saldivar, S. O. (2016). Technological and Engineering Trends for Production of Gluten-Free Beers. Food Engineering Reviews, 8 (4), 468–482. https://doi.org/10.1007/s12393-016-9142-6

- Dabija, A., Ciocan, M. E., Chetrariu, A., Codină, G. G. (2022). Buckwheat and Amaranth as Raw Materials for Brewing, a Review. Plants, 11 (6), 756. https://doi.org/10.3390/plants11060756

- Koshova, V., Mukoid, R., Parkhomenko, A. (2020). Influence of low-gluten grain crops on beer properties. Ukrainian Food Journal, 9 (3), 600–609. https://doi.org/10.24263/2304-974x-2020-9-3-9

- Brasil, V. C. B., Guimarães, B. P., Evaristo, R. B. W., Carmo, T. S., Ghesti, G. F. (2021). Buckwheat (Fagopyrum esculentum Moench) characterization as adjunct in beer brewing. Food Science and Technology, 41, 265–272. https://doi.org/10.1590/fst.15920

- Buiatti, S., Bertoli, S., Passaghe, P. (2017). Influence of gluten-free adjuncts on beer colloidal stability. European Food Research and Technology, 244 (5), 903–912. https://doi.org/10.1007/s00217-017-3010-3

- Dabija, A., Ciocan, M. E., Chetrariu, A., Mirzan, D. (2021). Comparative evaluation of the physico-chemical characteristics of buckwhweat malt and barley malt. 21st SGEM International Multidisciplinary Scientific GeoConference Proceedings 2021 Nano Bio Green and Space Technologies for Sustainable Future. https://doi.org/10.5593/sgem2021/6.1/s25.13

- Gumienna, M., Górna, B. (2020). Gluten hypersensitivities and their impact on the production of gluten-free beer. European Food Research and Technology, 246 (11), 2147–2160. https://doi.org/10.1007/s00217-020-03579-9

- Tanashkina, T., Peregoedova, A., Semenyuta, A., Boyarova, M. (2020). Gluten-free Buckwheat Kvass with Aromatic Raw Materials. Food Processing: Techniques and Technology, 50 (1), 70–78. https://doi.org/10.21603/2074-9414-2020-1-70-78

- Kim, S.-L., Kim, S.-K., Park, C.-H. (2004). Introduction and nutritional evaluation of buckwheat sprouts as a new vegetable. Food Research International, 37 (4), 319–327. https://doi.org/10.1016/j.foodres.2003.12.008

- Serikbaeva, A., Tnymbaeva, B., Mardar, M., Tkachenko, N., Ibraimova, S., Uazhanova, R. (2021). Determining optimal process parameters for sprouting buckwheat as a base for a food seasoning of improved quality. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 6–16. https://doi.org/10.15587/1729-4061.2021.237369

- Al-Taher, F., Nemzer, B. (2023). Effect of Germination on Fatty Acid Composition in Cereal Grains. Foods, 12 (17), 3306. https://doi.org/10.3390/foods12173306

- Dumitru, C., Dinica, R. M., Bahrim, G.-E., Vizireanu, C., Baroiu, L., Iancu, A. V., Draganescu, M. (2021). New Insights into the Antioxidant Compounds of Achenes and Sprouted Buckwheat Cultivated in the Republic of Moldova. Applied Sciences, 11 (21), 10230. https://doi.org/10.3390/app112110230

- Liu, C.-L., Chen, Y.-S., Yang, J.-H., Chiang, B.-H. (2007). Antioxidant Activity of Tartary (Fagopyrum tataricum (L.) Gaertn.) and Common ( Fagopyrum esculentum Moench) Buckwheat Sprouts. Journal of Agricultural and Food Chemistry, 56 (1), 173–178. https://doi.org/10.1021/jf072347s

- Kim, Y. S., Kim, J. G., Lee, Y. S., Kang, I. J. (2005). Comparison of the chemical components of buckwheat seed and sprout. Journal of the Korean Society of Food Science and Nutrition, 34 (1), 81–86. https://doi.org/10.3746/jkfn.2005.34.1.081

- Yıltırak, S., Kocadağlı, T., Evrim Çelik, E., Özkaynak Kanmaz, E., Gökmen, V. (2022). Effects of sprouting and fermentation on the formation of Maillard reaction products in different cereals heated as wholemeal. Food Chemistry, 389, 133075. https://doi.org/10.1016/j.foodchem.2022.133075

- Yıltırak, S., Kocadağlı, T., Çelik, E. E., Özkaynak Kanmaz, E., Gökmen, V. (2021). Effects of Sprouting and Fermentation on Free Asparagine and Reducing Sugars in Wheat, Einkorn, Oat, Rye, Barley, and Buckwheat and on Acrylamide and 5-Hydroxymethylfurfural Formation during Heating. Journal of Agricultural and Food Chemistry, 69 (32), 9419–9433. https://doi.org/10.1021/acs.jafc.1c03316

- Aloo, S. O., Ofosu, F. K., Kilonzi, S. M., Shabbir, U., Oh, D. H. (2021). Edible Plant Sprouts: Health Benefits, Trends, and Opportunities for Novel Exploration. Nutrients, 13 (8), 2882. https://doi.org/10.3390/nu13082882

- Zenkova, M., Melnikova, L., Timofeeva, V. (2023). Non-Alcoholic Beverages from Sprouted Buckwheat: Technology and Nutritional Value. Food Processing: Techniques and Technology, 53 (2), 316–325. https://doi.org/10.21603/2074-9414-2023-2-2435

- Emch, A. W., Burroughs, S., Gaspar-Hernandez, J., Waite-Cusic, J. G. (2021). Salmonella Growth during the Soaking Step of ‘Sprouted’ Grain, Nut, and Seed Production. Food Protection Trends, 41 (3), 314. https://doi.org/10.4315/1541-9576-41.3.314

- Zenkova, M., Melnikova, L. (2022). Microbiological Assessment of Wheat and Buckwheat Sprouting Process. Food Processing: Techniques and Technology, 51 (4), 795–804. https://doi.org/10.21603/2074-9414-2021-4-795-804

- Ding, J., Feng, H. (2019). Controlled germination for enhancing the nutritional value of sprouted grains. Sprouted Grains, 91–112. https://doi.org/10.1016/b978-0-12-811525-1.00005-1

- Kovalova, O., Vasylieva, N., Haliasnyi, I., Gavrish, T., Dikhtyar, A., Andrieieva, S. et al. (2023). Development of buckwheat groats production technology using plasma-chemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 6 (11 (126)), 59–72. https://doi.org/10.15587/1729-4061.2023.290584

- Kovaliova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Mandych, O., Hontar, T. et al. (2023). Development of a technology for the production of germinated flaxseed using plasma-chemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 6–19. https://doi.org/10.15587/1729-4061.2023.284810

- Kovalova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Haliasnyi, I., Gontar, T. et al. (2023). Determining the effect of plasmochemically activated aqueous solutions on the bioactivation process of sea buckthorn seeds. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 99–111. https://doi.org/10.15587/1729-4061.2023.275548

- Kovaliova, О., Pivovarov, О., Vasylieva, N., Koshulko, V. (2023). Obtaining of rice malt with the use of plasma-chemically activated aqueous solutions. Food Science and Technology, 16 (4). https://doi.org/10.15673/fst.v16i4.2542

- Pivovarov, O., Kovaliova, O. (2019). Features of grain germination with the use of aqueous solutions of fruit acids. Food Science and Technology, 13 (1). https://doi.org/10.15673/fst.v13i1.1334

- Pivovarov, O., Kovaliova, O., Khromenko, T., Shuliakevych, Z. (2017). Features of obtaining malt with use of aqueous solutions of organic acids. Food Science and Technology, 11 (4). https://doi.org/10.15673/fst.v11i4.728

- Pivovarov, O. A., Kovalоva, O. S., Matsyuk, Ch. V. (2022). Innovative grain germination stimulators of natural origin. Science, Technologies, Innovation, 4 (24), 31–44. https://doi.org/10.35668/2520-6524-2022-4-03

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. https://doi.org/10.15587/1729-4061.2020.215160

- Pivovarov, O., Kovaliova, O., Koshulko, V. (2020). Effect of plasmochemically activated aqueous solution on process of food sprouts production. Ukrainian Food Journal, 9 (3), 576–587. https://doi.org/10.24263/2304-974x-2020-9-3-7

- Pivovarov, О., Kovalova, О., Koshulko, V., Aleksandrova, A. (2022). Study of use of antiseptic ice of plasma-chemically activated aqueous solutions for the storage of food raw materials. Food Science and Technology, 15 (4). https://doi.org/10.15673/fst.v15i4.2260

- Pivovarov, О., Kovalova, О., Koshulko, V. (2022). Disinfection of marketable eggs by plasma-chemically activated aqueous solutions. Food Science and Technology, 16 (1). https://doi.org/10.15673/fst.v16i1.2289

- Pivovarov, О., Kovaliova, О., Koshulko, V. (2022). Effect of plasma-chemically activated aqueous solutions on the process of disinfection of food production equipment. Food Science and Technology, 16 (3). https://doi.org/10.15673/fst.v16i3.2392

- Kovaliova, O., Pivovarov, O., Koshulko, V. (2020). Study of hydrothermal treatment of dried malt with plasmochemically activated aqueous solutions. Food Science and Technology, 14 (3). https://doi.org/10.15673/fst.v14i3.1799

- Kovalova, O. S. (2022). Innovatsiyna tekhnolohiya vyrobnytstva hrechanoi krupy. Proceedings of the XIV International Scientific and Practical Conference: Modern stages of scientific research development, 453–460. Available at: https://isg-konf.com/wp-content/uploads/2022/12/Modern-stages-of-scientific-research-development.pdf

- Evans, D. E., Redd, K., Haraysmow, S. E., Elvig, N., Metz, N., Koutoulis, A. (2014). The Influence of Malt Quality on Malt Brewing and Barley Quality on Barley Brewing with Ondea Pro, Compared by Small-Scale Analysis. Journal of the American Society of Brewing Chemists, 72 (3), 192–207. https://doi.org/10.1094/asbcj-2014-0630-01

- Calafiore, G. C., El Ghaoui, L. (2014). Optimization Models. Cambridge: Cambridge University Press. https://doi.org/10.1017/cbo9781107279667

- Greene, W. (2017). Econometric Analysis. London: Pearson Learning Solutions, 1176.

- Aggarwal, C. C., Reddy, C. K. (2014). Data Clustering: Algorithms and Applications. London: Chapman and Hall/CRC, 652.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Olena Kovalova, Natalia Vasylieva, Ivan Haliasnyi, Tatiana Gavrish, Aliona Dikhtyar, Svitlana Andrieieva, Tatiana Gontar, Olha Osmanova, Svitlana Omelchenko, Oleksandr Ashtaiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.