Determining heat and mass exchange kinetic in a column heat exchanger with direct phases contact

DOI:

https://doi.org/10.15587/1729-4061.2024.298798Keywords:

contact heat exchanger, dual-flow tray, heat exchange, sodium chloride solution, gas emissions, utilization of thermal waste, non-traditional sources of thermal energy, enthalpy transfer coefficientAbstract

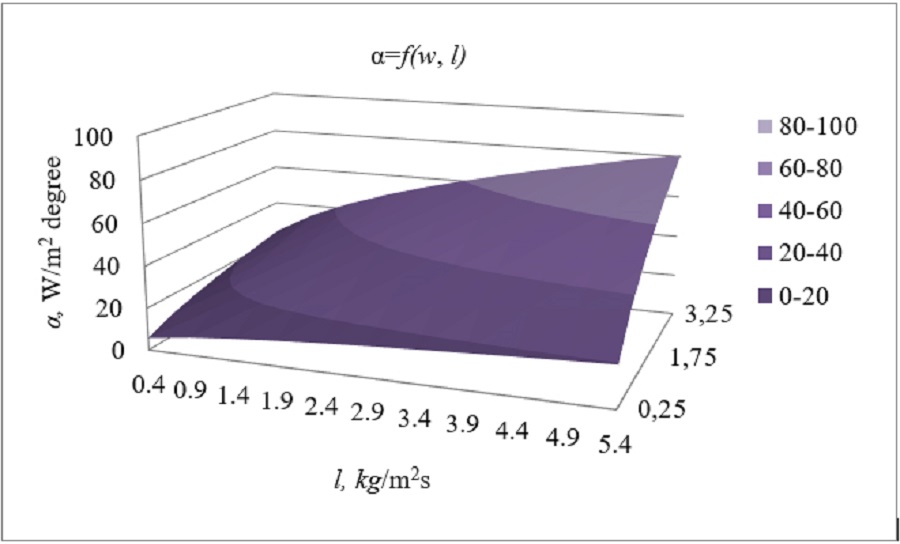

The object of this study was the processes of heat and mass transfer in a column heat exchanger with direct phases contact. The investigated problem is related to the need to determine the estimates of the kinetic characteristics of heat exchange during the concentration of solutions in a contact heat exchanger equipped with dual-flow trays. In particular, it was assumed that the determination of the influence of the gas velocity in the apparatus and the density of liquid irrigation of the plates, as well as the geometry of the plates, on the kinetic coefficients would make it possible to reveal the patterns of heat and mass exchange between the liquid and the air in contact with it in the column apparatus. It was determined that to increase the intensity of mass transfer in the gas and heat transfer in the liquid, it is necessary to increase the gas velocity and irrigation density. Then the gas velocity and irrigation density have approximately the same effect on the intensity of mass transfer in the gas and heat transfer in the liquid. When studying the effect of the geometry of the plate on the kinetic coefficients of heat transfer in the liquid and mass transfer in the gas, it was established that the value of the portion of the free cross section of the plate has a decisive influence on the value of the considered kinetic coefficients.

A generalized equation was built, which makes it possible not only to calculate the enthalpy transfer coefficient during the interaction of sodium chloride solution with air but also to determine the limiting stage of this process.

The results could be used to design a unit for concentrating a hot solution of sodium chloride by evaporating water during blowing with air in a contact heat exchanger. This would make it possible to obtain crystalline sodium chloride using secondary energy resources and other non-traditional sources of thermal energy

References

- Kalantari, H., Amiri, L., Ghoreishi‐Madiseh, S. A. (2021). Analysis of the performance of direct contact heat exchange systems for application in mine waste heat recovery. International Journal of Energy Research, 46 (1), 290–307. https://doi.org/10.1002/er.6734

- Jacobs, H. R. (2011). Direct contact heat exchangers. A-to-Z Guide to Thermodynamics, Heat and Mass Transfer, and Fluids Engineering. https://doi.org/10.1615/atoz.d.direct_contact_heat_exchangers

- Lage, P. L. C., Campos, F. B. (2004). Advances in Direct Contact Evaporator Design. Chemical Engineering & Technology, 27 (1), 91–96. https://doi.org/10.1002/ceat.200401760

- Sergeev, Yu. A., Gorlovskii, D. M., Basargin, B. N., Kucheryavyi, V. I., Gladkov, V. A. (1980). Constructions of injection-type evaporational heat exchangers (patent review). Chemical and Petroleum Engineering, 16 (6), 374–380. https://doi.org/10.1007/bf01148518

- Jouhara, H., Khordehgah, N., Almahmoud, S., Delpech, B., Chauhan, A., Tassou, S. A. (2018). Waste heat recovery technologies and applications. Thermal Science and Engineering Progress, 6, 268–289. https://doi.org/10.1016/j.tsep.2018.04.017

- Taranenko, G. (2017). Hydrodynamic modeling of the operating regimes of dual-flow plates installed in columns of various diameter. ScienceRise, 6, 34–38. https://doi.org/10.15587/2313-8416.2017.103536

- TSeytlin, M. A., Rayko, V. F., Gareev, A. T. (1996). Kontaktnoe ohlazhdenie szhatyh gazov. Respublikanskiy mezhvedomstvennyy nauchno-tehnicheskiy sbornik «Energetika», 55, 85–87.

- Suhanov, A. M. Sterle, E. G. et al. (1987). Gradirnya. A.S. SU1281860A1. declareted: 01.07.87. Bul. No. 1.

- Frumin, V. M. (2000). Desorbtsiya ammiaka v distillere sodovogo proizvodstva. Vestnik Har'kovskogo gos. Politehnicheskogo Universiteta, 118, 41–42.

- Boulama, K., Galanis, N., Orfi, J. (2004). Heat and mass transfer between gas and liquid streams in direct contact. International Journal of Heat and Mass Transfer, 47 (17-18), 3669–3681. https://doi.org/10.1016/j.ijheatmasstransfer.2004.04.004

- Guo, Q., Qi, X., Sun, P., Guo, P. (2019). New explicit analytical solutions of equations for heat and mass transfer in a cooling tower energy system. Advances in Mechanical Engineering, 11 (12), 168781401989614. https://doi.org/10.1177/1687814019896147

- Luk'yanenko, T. V. (1985). Issledovanie isparitel'nogo protsessa ohlazhdeniya vody na krupnodarchatyh tarelkah. Sbornik nauchnyh trudov Gosudarstvennogo nauchno-issledovatel'skogo i proektnogo instituta osnovnoy himii (NIOHIM). Seriya: Intensifikatsiya tehnologicheskih protsessov i apparatov sodovogo i smezhnyh proizvodstv, 60.

- Mass-transfer operations. McGraw-Hill. Available at: https://www.usb.ac.ir/FileStaff/6885_2019-4-27-19-27-38.pdf

- Tseitlin, M., Raiko, V., Shestopalov, O. (2020). Heat Exchange Characteristics of Trays for Concentrating Solutions in Direct Contact with Hot Gas Emissions. Lecture Notes in Mechanical Engineering, 396–404. https://doi.org/10.1007/978-3-030-50491-5_38

- Mc'Adams, W. H., Pohlens, J. B., John, R. C. (1949). Transfer of heat and mass between air and water. Chemical Engineering Progres, 45, 241–259.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Musii Tseitlin, Andrii Shkop, Oleksіi Shestopalov, Valentina Raiko, Nataliia Ponomarova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.