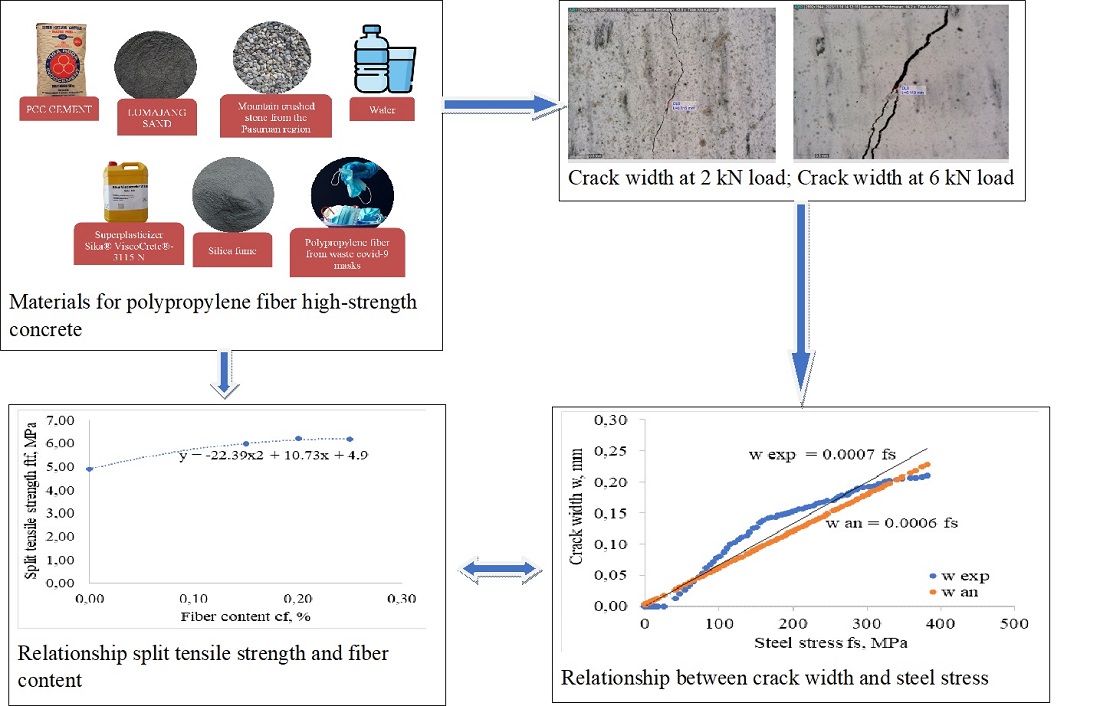

Identifying the influence of split tensile strength to crack width of high-strength reinforced concrete beam with polypropylene fiber from medical mask waste

DOI:

https://doi.org/10.15587/1729-4061.2024.298842Keywords:

split tensile strength, crack width, high-strength, reinforced concrete beam, medical mask waste, polypropylene fiberAbstract

Cracks in concrete structures due to tensile weakness can be repaired by using fiber concrete, including medical mask waste as an additive in high-strength concrete mixes. This research the influence of polypropylene fiber from medical mask waste on the mechanical characteristics, flexural behavior, and crack width of high-strength reinforced concrete (RC) beams. The initial stage involved examining the properties of the concrete constituent materials. The testing process was based on a high-strength concrete mix design using the Aitchin method mix design sheet. Compressive strength and split tensile strength were tested at fiber content (0 %, 0.15 %, 0.20 %, and 0.25 %). The three-point flexural testing procedure was carried out at 28 days on 1200×100×150 (mm) RC beams. The use of LVDT, strain gauge, and other measuring devices supported the acquisition of the required data. The results showed that the split tensile strength reached the optimum value of 66.19 MPa at 0.24 % fiber content. Polypropylene fiber from medical mask waste in RC beams showed a positive impact on reducing crack width at increased split tensile strength. Waste mask fiber content of 0.15 %, 0.20 % and 0.25 % gave stable and better results compared to 0 % content (no fiber). With high steel stress (fs), and high strain, it offers the potential to improve the mechanical properties of high-strength concrete, thereby reducing the width of cracks that occur. This improves the tensile weakness of the concrete. The effect of split tensile strength on the crack width (w) of beams with the formula approach: wexp=3.74ftf-1.513, wan=0.187ftf-0.022 shows that the experimental results have a significant effect on decreasing the crack width that occurs in high-strength RC beams, thereby improving the quality of concrete

Supporting Agency

- We thank LPPM Brawijaya University for providing financial support in the Doctoral Dissertation Research (PDD) DRTPM DIKTI TA Research Program 2023, thus assisting in the completion of this research.

References

- Harussani, M. M., Sapuan, S. M., Rashid, U., Khalina, A., Ilyas, R. A. (2022). Pyrolysis of polypropylene plastic waste into carbonaceous char: Priority of plastic waste management amidst COVID-19 pandemic. Science of The Total Environment, 803, 149911. https://doi.org/10.1016/j.scitotenv.2021.149911

- Prioleau, R. M. (1995). Recycling of Polypropylene. Plastics, Rubber, and Paper Recycling, 80–88. https://doi.org/10.1021/bk-1995-0609.ch007

- Mavrokefalidis, D. (2020). Coronavirus face masks ‘could have a devastating effect on the environment’. Energy Live. Available at: https://www.energylivenews.com/2020/03/17/coronavirus-face-masks-could-have-a-devastating-effect-on-the-environment/

- Sadiqul Islam, G. M., Gupta, S. D. (2016). Evaluating plastic shrinkage and permeability of polypropylene fiber reinforced concrete. International Journal of Sustainable Built Environment, 5 (2), 345–354. https://doi.org/10.1016/j.ijsbe.2016.05.007

- Kilmartin-Lynch, S., Saberian, M., Li, J., Roychand, R., Zhang, G. (2021). Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. Journal of Cleaner Production, 296, 126460. https://doi.org/10.1016/j.jclepro.2021.126460

- Xu, H., Shao, Z., Wang, Z., Cai, L., Li, Z., Jin, H., Chen, T. (2020). Experimental study on mechanical properties of fiber reinforced concrete: Effect of cellulose fiber, polyvinyl alcohol fiber and polyolefin fiber. Construction and Building Materials, 261, 120610. https://doi.org/10.1016/j.conbuildmat.2020.120610

- Skarżyński, Ł., Tejchman, J. (2021). Investigations on fracture in reinforced concrete beams in 3-point bending using continuous micro-CT scanning. Construction and Building Materials, 284, 122796. https://doi.org/10.1016/j.conbuildmat.2021.122796

- Yin, S., Tuladhar, R., Shi, F., Combe, M., Collister, T., Sivakugan, N. (2015). Use of macro plastic fibres in concrete: A review. Construction and Building Materials, 93, 180–188. https://doi.org/10.1016/j.conbuildmat.2015.05.105

- Naotunna, C. N., Samarakoon, S. M. S. M. K., Fosså, K. T. (2021). Experimental investigation of crack width variation along the concrete cover depth in reinforced concrete specimens with ribbed bars and smooth bars. Case Studies in Construction Materials, 15, e00593. https://doi.org/10.1016/j.cscm.2021.e00593

- Soehardjono, A., Wibowo, A., Nuralinah, D., Aditya, C. (2023). Identifying the influence of reinforcement ratio on crack behaviour of rigid pavement. Eastern-European Journal of Enterprise Technologies, 5 (7 (125)), 87–94. https://doi.org/10.15587/1729-4061.2023.290035

- Gribniak, V., Rimkus, A., Pérez Caldentey, A., Sokolov, A. (2020). Cracking of concrete prisms reinforced with multiple bars in tension–the cover effect. Engineering Structures, 220, 110979. https://doi.org/10.1016/j.engstruct.2020.110979

- He, S., Mustafa, S., Chang, Z., Liang, M., Schlangen, E., Luković, M. (2023). Ultra-thin Strain Hardening Cementitious Composite (SHCC) layer in reinforced concrete cover zone for crack width control. Engineering Structures, 292, 116584. https://doi.org/10.1016/j.engstruct.2023.116584

- Ningrum, D., Soehardjono, A., Suseno, H., Wibowo, A. (2023). Analysis of the effect of using Covid-19 medical mask waste with polypropylene on the compressive strength and split tensile strength of high-performance concrete. Eastern-European Journal of Enterprise Technologies, 1 (6 (121)), 40–46. https://doi.org/10.15587/1729-4061.2023.272529

- Lloyd, N. A., Rangan, B. V. (1994). High-Performance Concrete Columns. “SP-149: High-Performance Concrete - Proceedings, International Conference Singapore, 1994.” https://doi.org/10.14359/4167

- Krisnamurti, Soehardjono, A., Zacoeb, A., Wibowo, A. (2018). Development of Mix Design Method in Efforts to Increase Concrete Performance Using Portland Pozzolana Cement (PPC). Journal of Physics: Conference Series, 953, 012016. https://doi.org/10.1088/1742-6596/953/1/012016

- Uomoto, T., Ishibashi, T., Nobuta, Y., Satoh, T., Kawano, H., Takewaka, K., Uji, K. (2008). Standard Specifications for Concrete Structures-2007 by Japan Society of Civil Engineers. Concrete Journal, 46 (7), 3–14. https://doi.org/10.3151/coj1975.46.7_3

- El Aal, A. A., Abdullah, G. M. S., Qadri, S. M. T., Abotalib, A. Z., Othman, A. (2022). Advances on concrete strength properties after adding polypropylene fibers from health personal protective equipment (PPE) of COVID-19: Implication on waste management and sustainable environment. Physics and Chemistry of the Earth, Parts A/B/C, 128, 103260. https://doi.org/10.1016/j.pce.2022.103260

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Diana Ningrum, Agoes Soehardjono, Hendro Suseno, Ari Wibowo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.