Development of programmed trajectories based on the mobility degrees of manipulation robot with a spherical coordinate system for removing oxide film in the production of commercial magnesium

DOI:

https://doi.org/10.15587/1729-4061.2024.298912Keywords:

foundry conveyor, oxide film, manipulation robot, trajectory planning, quadratic interpolationAbstract

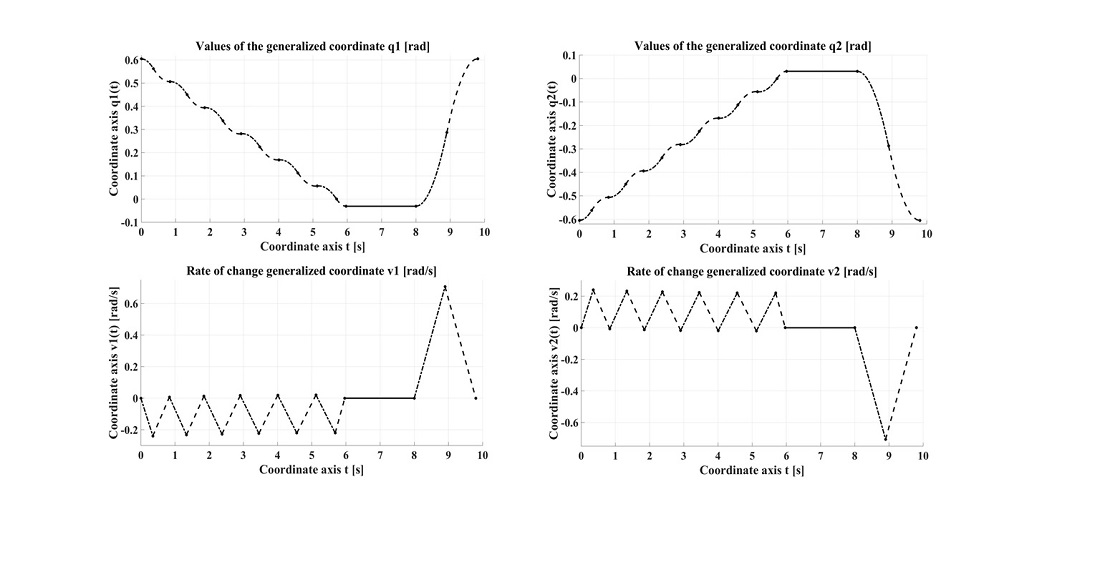

The object of this study is to robotize the technological operation of removing the oxide film from the surface of a magnesium melt poured into continuously moving molds of a casting conveyor for the production of commercial magnesium. To robotize this technological operation, it is proposed to use a two-armed manipulation robot with a spherical coordinate system, which has six degrees of mobility. Software trajectories have been developed according to the degrees of mobility of the manipulation robot in terms of position, speed, and acceleration to perform the technological operation of removing the oxide film from the surface of the magnesium melt poured into the moving molds of the foundry conveyor. Programmed trajectories are described by quadratic polynomials that satisfy restrictions on the values of the generalized coordinate, velocity, and acceleration. These limitations are determined by the design features and energy capabilities of the degrees of mobility drives of the manipulation robot. Programmed trajectories along the first and second degrees of freedom compensate for the continuous movement of the molds of the foundry conveyor. Programmed trajectories along the third and fourth degrees of mobility enable the collection of the oxide film from the surface of the magnesium melt. Programmed trajectories along the fifth and sixth degrees of freedom enable the discharge of the collected oxide film into a special container. The reliability of the developed programmed trajectories is confirmed by the simulation results using MATLAB version R2015b. Based on the results, a cyclogram for controlling a manipulation robot has been constructed to perform the technological operation of removing the oxide film in the production of commercial magnesium. The results could be used in the robotization of technological processes for removing the oxide film in the production of commercial magnesium or similar foundries

References

- Lebedev, V. A., Sedyh, V. I. (2010). Metallurgiya magniya. Ekaterinburg: UGTU-UPI, 174.

- Yanushevskiy, A. S., Korshunov, V. V. (2017). Proizvodstvo magnievyh otlivok v metallicheskie formy. Omskiy nauchnyy vestnik. Mashinostroenie, mashinovedenie, 1 (151), 45–48.

- Beisembayev, A., Yerbossynova, A., Pavlenko, P., Baybatshaev, M. (2023). Development of a software trajectory of a manipulation robot for removing oxide film in the production of commercial magnesium. KazATC Bulletin, 127 (4), 160–169. https://doi.org/10.52167/1609-1817-2023-127-4-160-169

- Beisembayev, A., Yerbossynova, A., Pavlenko, P., Baibatshayev, M. (2023). Planning trajectories of a manipulation robot with a spherical coordinate system for removing oxide film in the production of commercial lead, zinc. Eastern-European Journal of Enterprise Technologies, 4 (2 (124)), 80–89. https://doi.org/10.15587/1729-4061.2023.286463

- Ross, L. T., Fardo, S. W., Walach, M. F. (2018). Industrial robotics fundamentals: theory and applications. The Goodheart-Willcox Company, Inc., 463 p.

- Ruiz-Celada, O., Verma, P., Diab, M., Rosell, J. (2022). Automating Adaptive Execution Behaviors for Robot Manipulation. IEEE Access, 10, 123489–123497. https://doi.org/10.1109/access.2022.3223995

- Akbari, A., Lagriffoul, F., Rosell, J. (2018). Combined heuristic task and motion planning for bi-manual robots. Autonomous Robots, 43 (6), 1575–1590. https://doi.org/10.1007/s10514-018-9817-3

- Xu, S., Ou, Y., Duan, J., Wu, X., Feng, W., Liu, M. (2019). Robot trajectory tracking control using learning from demonstration method. Neurocomputing, 338, 249–261. https://doi.org/10.1016/j.neucom.2019.01.052

- Biagiotti, L., Melchiorri, C. (2019). Trajectory generation via FIR filters: A procedure for time-optimization under kinematic and frequency constraints. Control Engineering Practice, 87, 43–58. https://doi.org/10.1016/j.conengprac.2019.03.017

- Faroni, M., Beschi, M., Visioli, A., Pedrocchi, N. (2021). A real-time trajectory planning method for enhanced path-tracking performance of serial manipulators. Mechanism and Machine Theory, 156, 104152. https://doi.org/10.1016/j.mechmachtheory.2020.104152

- Dai, H., Lu, Z., He, M., Yang, C. (2023). A Gripper-like Exoskeleton Design for Robot Grasping Demonstration. Actuators, 12 (1), 39. https://doi.org/10.3390/act12010039

- Kazim, I. J., Tan, Y., Qaseer, L. (2021). Integration of DE Algorithm with PDC-APF for Enhancement of Contour Path Planning of a Universal Robot. Applied Sciences, 11 (14), 6532. https://doi.org/10.3390/app11146532

- Wu, G., Zhao, W., Zhang, X. (2020). Optimum time-energy-jerk trajectory planning for serial robotic manipulators by reparameterized quintic NURBS curves. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 235 (19), 4382–4393. https://doi.org/10.1177/0954406220969734

- Wang, L., Xiang, Y., Fox, D. (2020). Manipulation Trajectory Optimization with Online Grasp Synthesis and Selection. Robotics: Science and Systems XVI. https://doi.org/10.15607/rss.2020.xvi.033

- Su, C., Zhang, S., Lou, S., Wang, R., Cao, G., Yang, L., Wang, Q. (2020). Trajectory coordination for a cooperative multi-manipulator system and dynamic simulation error analysis. Robotics and Autonomous Systems, 131, 103588. https://doi.org/10.1016/j.robot.2020.103588

- Goritov, A. N., Goncharov, K. V. (2020). Motion trajectory planning for a multi-link manipulator in an unknown environment based on ant colony optimization. Proceedings of Tomsk State University of Control Systems and Radioelectronics, 23 (2), 55–64. https://doi.org/10.21293/1818-0442-2020-23-2-55-64

- Merlo, F., Vazzoler, G., Berselli, G. (2023). Eco-programming of industrial robots for sustainable manufacturing via dynamic time scaling of trajectories. Robotics and Computer-Integrated Manufacturing, 79, 102420. https://doi.org/10.1016/j.rcim.2022.102420

- Benotsmane, R., Dudás, L., Kovács, G. (2020). Trajectory Optimization of Industrial Robot Arms Using a Newly Elaborated “Whip-Lashing” Method. Applied Sciences, 10 (23), 8666. https://doi.org/10.3390/app10238666

- Ostanin, M., Popov, D., Klimchik, A. (2018). Programming by Demonstration Using Two-Step Optimization for Industrial Robot. IFAC-PapersOnLine, 51 (11), 72–77. https://doi.org/10.1016/j.ifacol.2018.08.237

- French, K. D., Kim, J. H., Du, Y., Goeddel, E. M., Zeng, Z., Jenkins, O. C. (2023). Super Intendo: Semantic Robot Programming from Multiple Demonstrations for taskable robots. Robotics and Autonomous Systems, 166, 104397. https://doi.org/10.1016/j.robot.2023.104397

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Akambay Beisembayev, Anargul Yerbossynova, Petro Pavlenko, Mukhit Baibatshayev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.