The effect of carbon black percentage on mechanical properties and microstructure of polybutylene terephthalate/polyamide 6/carbon black blends

DOI:

https://doi.org/10.15587/1729-4061.2024.299067Keywords:

PBT/PA6 blend, PBT, carbon black, tensile strength, impact strength, microstructureAbstract

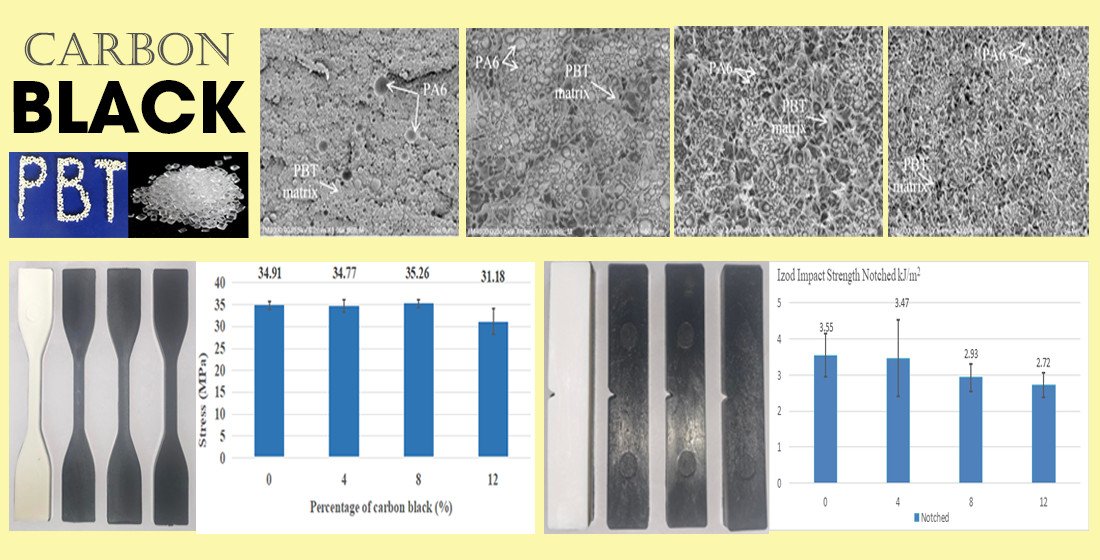

This study focuses on analyzing the influence of carbon black (CB) on Polybutylene terephthalate (PBT)/Polyamide 6 (PA6) blends. This study aims to solve the source of waste from toothbrush filament during production. This PBT/PA6 mixture does not meet the mechanical properties due to the incompatibility of these two plastics, which means this waste must be discarded and cannot be reused. When combined with CB, it creates a new type of plastic with more stable mechanical properties that can be applied in many areas of life and, at the same time, helps manufacturing businesses save on waste treatment costs. To create these PBT/PA6/CB blends, the research team used injection molding with a PBT/PA6 ratio of 75/25 combined with 0, 4, 8, and 12 % carbon black. The tensile and impact strength were tested according to the ASTM D638 and ASTM D256 standards. The results found that when adding 4 % CB to the PBT/PA6 plastic mixture, the tensile strength decreased from 34.9 to 34.8 MPa. Meanwhile, the tensile strength is improved when adding 8 % CB (35.3 MPa). At 12 % CB, a difference in tensile strength results, decreasing to 29.7 MPa. This result shows that the ratio 75/25 can give the best tensile strength value of the PBT/PA6 mixture with 8 wt. % CB. The impact strength was 3.5, 2.9, and 2.7 kJ/m2 according to 4, 8, and 12 % CB samples. Mechanical quality tests have shown that the tensile strength is improved when combining CB into the PBT/PA6 mixture, but the impact strength is reduced. SEM results show that most CB interacts with PBT/PA6 mainly because the PA6 particles are spherical and tend to separate easily from the mixture. The research found that increasing CB density worsens the bonding ability between PBT and PA6. These results help us provide experience for the most appropriate application for each purpose

References

- Mohanty, A. K., Vivekanandhan, S., Pin, J.-M., Misra, M. (2018). Composites from renewable and sustainable resources: Challenges and innovations. Science, 362 (6414), 536–542. https://doi.org/10.1126/science.aat9072

- Banik, K., Mennig, G. (2008). Effect of mold temperature on the long‐term viscoelastic behavior of polybutylene terepthalate. Polymer Engineering & Science, 48 (5), 957–965. https://doi.org/10.1002/pen.20989

- Li, H., Wang, J., Li, G., Lu, Y., Wang, N., Zhang, Q., Qu, X. (2016). Preparation of core-shell structured particle and its application in toughening PA6/PBT blends. Polymers for Advanced Technologies, 28 (6), 699–707. https://doi.org/10.1002/pat.3969

- Lievana, E., Karger‐Kocsis, J. (2003). Impact modification of PA‐6 and PBT by epoxy‐functionalized rubbers. Macromolecular Symposia, 202 (1), 59–66. https://doi.org/10.1002/masy.200351206

- Chiou, K.-C., Chang, F.-C. (2000). Reactive compatibilization of polyamide-6 (PA 6)/polybutylene terephthalate (PBT) blends by a multifunctional epoxy resin. Journal of Polymer Science Part B: Polymer Physics, 38 (1), 23–33. https://doi.org/10.1002/(sici)1099-0488(20000101)38:1<23::aid-polb3>3.0.co;2-y

- Wakita, N. (1993). Melt elasticity of incompatible blends of poly(butylene terephthalate)(PBT) and polyamide 6 (PA6). Polymer Engineering & Science, 33 (13), 781–788. https://doi.org/10.1002/pen.760331302

- Hu, J., Zhang, H.-B., Hong, S., Jiang, Z.-G., Gui, C., Li, X., Yu, Z.-Z. (2014). Simultaneous Improvement in Both Electrical Conductivity and Toughness of Polyamide 6 Nanocomposites Filled with Elastomer and Carbon Black Particles. Industrial & Engineering Chemistry Research, 53 (6), 2270–2276. https://doi.org/10.1021/ie4035785

- Chang, B. P., Mohanty, A. K., Misra, M. (2018). Tuning the compatibility to achieve toughened biobased poly(lactic acid)/poly(butylene terephthalate) blends. RSC Advances, 8 (49), 27709–27724. https://doi.org/10.1039/c8ra05161e

- Tran, K. L., Pham, T. H. N., Tran, M. T. U. (2023). Research on tensile strength of PBT/PA6/activated carbon composite materials. Proceeding The International Conference on Science, Education and Viable Engineering (ICSEVEN 2023), 207–215.

- Pham, T. H. N., Phuc, L. H. T., Ngan, L. D. H., Triem, T. D., Uyen, T. M. T., Van Thuc, N. et al. (2023). Effect of Glass Fiber on the Tensile Strength of Poly(butylene terephthalate)/Polyamide 6 Blends. Polymer Science, Series A, 65 (5), 543–549. https://doi.org/10.1134/s0965545x23701158

- Yang, H., Li, B., Zhang, Q., Du, R., Fu, Q. (2011). Simultaneous enhancement of electrical conductivity and impact strength via formation of carbon black‐filler network in PP/EPDM Blends. Polymers for Advanced Technologies, 22 (6), 857–862. https://doi.org/10.1002/pat.1588

- Huang, J. (2002). Carbon black filled conducting polymers and polymer blends. Advances in Polymer Technology, 21 (4), 299–313. https://doi.org/10.1002/adv.10025

- Li, H., Tuo, X., Guo, B.-H., Yu, J., Guo, Z.-X. (2021). Comparison of Three Interfacial Conductive Networks Formed in Carbon Black-Filled PA6/PBT Blends. Polymers, 13 (17), 2926. https://doi.org/10.3390/polym13172926

- Tang, L., Wang, L., Chen, P., Fu, J., Xiao, P., Ye, N., Zhang, M. (2017). Toughness of ABS/PBT blends: The relationship between composition, morphology, and fracture behavior. Journal of Applied Polymer Science, 135 (13). https://doi.org/10.1002/app.46051

- Xiao, J., Hu, Y., Yang, L., Cai, Y., Song, L., Chen, Z., Fan, W. (2006). Fire retardant synergism between melamine and triphenyl phosphate in poly(butylene terephthalate). Polymer Degradation and Stability, 91 (9), 2093–2100. https://doi.org/10.1016/j.polymdegradstab.2006.01.018

- Fang, H., Wu, F. (2014). Nonisothermal crystallization kinetics of poly(butylene terephthalate)/multiwalled carbon nanotubes nanocomposites prepared by in situ polymerization. Journal of Applied Polymer Science, 131 (19). https://doi.org/10.1002/app.40849

- Pham, N. T.-H. (2021). A Study of Recycled Poly(butylene terephthalate) and Low-Density Polyethylene Blend. Polymer Science, Series A, 63 (6), 800–803. https://doi.org/10.1134/s0965545x21060080

- Sato, Y., Masumizu, S., Sakaue, K., Koyanagi, J., Ohtani, A., Sakai, T. (2022). Evaluation of viscoelastic non-isochoric plastic behavior of PBT and PA6. Mechanics of Time-Dependent Materials, 27 (3), 829–841. https://doi.org/10.1007/s11043-022-09552-1

- Shuidong, Z., Lingcao, T., Jizhao, L., Hanxiong, H., Guo, J. (2014). Relationship between structure and properties of reprocessed glass fiber reinforced flame retardant poly(butylene terephthalate). Polymer Degradation and Stability, 105, 140–149. https://doi.org/10.1016/j.polymdegradstab.2014.04.009

- Jubinville, D., Chang, B. P., Pin, J.-M., Mohanty, A. K., Misra, M. (2019). Synergistic thermo-oxidative maleation of PA11 as compatibilization strategy for PA6 and PBT blend. Polymer, 179, 121594. https://doi.org/10.1016/j.polymer.2019.121594

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Phan Hieu Hua, Quoc Bao Ngo, Trong Kien Ha, Thi Hong Nga Pham, Vinh Tien Nguyen, Chi Thanh Nguyen, Quan Anh Pham

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.