Identification of the low-rank coals thermal heating behavior

DOI:

https://doi.org/10.15587/1729-4061.2024.299538Keywords:

coal, thermal heating, temperature, decomposition, volatile fuel gases, energy efficiencyAbstract

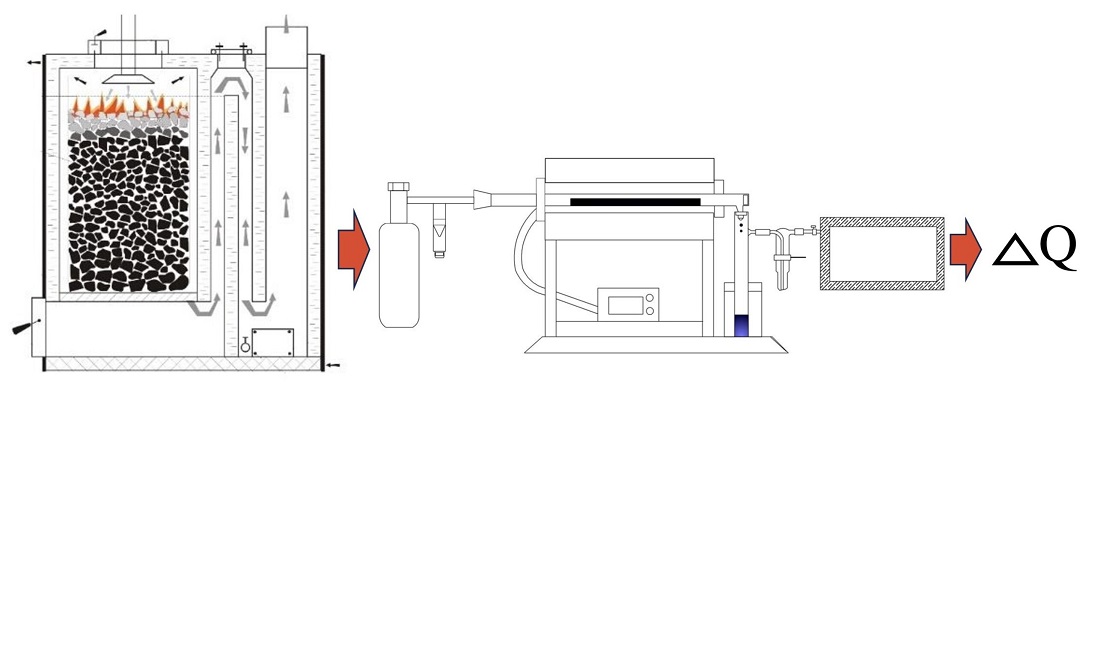

In this study, the object of the research is low-rank coal during the process of thermal heating of five types: brown, high moisture brown, long-flame, coke weakly sintering and coke fusinite.

In the research, when conducting thermal and gas analysis in inert media, the problem of using low-rank coal in the thermal heating process to obtain volatile fuel gases was solved by identifying the quantitative and qualitative performance of its behavior. Quantitative indicators are determined as the mass of thermal destruction products: the mass of coal tar and gas products and semi-coke under optimal temperature conditions of their maximum release. Qualitative indicators of coal behavior are components of thermal decomposition products. It is revealed that the behavior of low-rank coals in the process of thermal heating is determined by the degree of metamorphism. In this case, long-flame and brown coals have a lower release of volatile fuel gases than coke weakly sintering and coke fusinite coals due to a lower degree of metamorphism and greater degrees of thermal oxidation and dehydration.

Thermal decomposition component ranges consisting of polyaromatic fragments (HCN, C6H12, C4H5N), greenhouse gases (CH4 and CO2), toxic gases (H2S and NH3) and synthesis gases (CO and H2) have the highest share of release. Optimal temperature conditions and ranges for the release of low molecular weight gases used as high calorific volatile fuel gases are obtained.

The results can be used in the design, optimization and construction of thermal heating equipment, correction of gasification and pyrolysis processes. Moreover, they can be applied in localized coal tar spots minimization technologies and for designing targeted gases extraction

References

- Aisyah, L., Rulianto, D., Wibowo, C. S. (2015). Analysis of the Effect of Preheating System to Improve Efficiency in LPG-fuelled Small Industrial Burner. Energy Procedia, 65, 180–185. https://doi.org/10.1016/j.egypro.2015.01.055

- Woźniak, G., Longwic, R., Szydło, K., Kryłowicz, A., Kryłowicz, J., Juszczak, R. (2018). The efficiency of the process of coal gasification in the presence of hydrogen. E3S Web of Conferences, 46, 00030. https://doi.org/10.1051/e3sconf/20184600030

- Hoya, R., Fushimi, C. (2017). Thermal efficiency of advanced integrated coal gasification combined cycle power generation systems with low-temperature gasifier, gas cleaning and CO2 capturing units. Fuel Processing Technology, 164, 80–91. https://doi.org/10.1016/j.fuproc.2017.04.014

- Global coal production slumps in 2020, yet looks to increase in 2021. International energy agency. Available at: https://www.iea.org/reports/coal-2020/supply

- Liu, H., Zhang, K. (2021). Mechanism Exploration and application on Improving Coal Permeability by Heat Treating. IOP Conference Series: Earth and Environmental Science, 861 (6), 062076. https://doi.org/10.1088/1755-1315/861/6/062076

- Zhang, L., Wang, G., Xue, Q., Zuo, H., She, X., Wang, J. (2021). Effect of preheating on coking coal and metallurgical coke properties: A review. Fuel Processing Technology, 221, 106942. https://doi.org/10.1016/j.fuproc.2021.106942

- Guo, X., Xiao, Y., Zhao, L., Shi, L., Xue, X., Li, X., Liu, Z. (2021). Combustion behaviors of various coals and chars: From covalent bonds’ and radicals’ perspective. Fuel, 297, 120749. https://doi.org/10.1016/j.fuel.2021.120749

- Li, X., Zeng, Q. (2022). HRTEM analysis of the aggregate structure and ultrafine microporous characteristics of Xinjiang Zhundong coal under heat treatment. Scientific Reports, 12 (1). https://doi.org/10.1038/s41598-022-09113-z

- Zhang, J., Zhu, J., Liu, J. (2023). Experimental Studies on Preheating Combustion Characteristics of Low-Rank Coal with Different Particle Sizes and Kinetic Simulation of Nitrogen Oxide. Energies, 16 (20), 7078. https://doi.org/10.3390/en16207078

- Zhu, G., Xu, L., Wang, S., Niu, F., Li, T., Hui, S., Niu, Y. (2024). Synergistic reduction on PM and NO source emissions during preheating-combustion of pulverized coal. Fuel, 361, 130699. https://doi.org/10.1016/j.fuel.2023.130699

- Baubek, A., Atyaksheva, A., Zhumagulov, M., Kartjanov, N., Plotnikova, I., Chicherina, N. (2021). Complex Studies of the Innovative Vortex Burner Device with Optimization of Design. Studies in Systems, Decision and Control, 139–153. https://doi.org/10.1007/978-3-030-68103-6_13

- Kukharets, S., Tsyvenkova, N., Yaroslav, Y., Grabar, I., Нolubenko, A. (2018). The results of study into the effect of airsteam blast on the lowgrade fuel gasification process. Eastern-European Journal of Enterprise Technologies, 6 (8 (96)), 86–96. https://doi.org/10.15587/1729-4061.2018.147545

- Mergalimova, A., Ongar, B., Georgiev, A., Каlieva, K., Abitaeva, R., Bissenbayev, P. (2021). Parameters of heat treatment of coal to obtain combustible volatile substances. Energy, 224, 120088. https://doi.org/10.1016/j.energy.2021.120088

- Atyaksheva, A. V., Atyaksheva, A. D., Ryvkina, N. V., Yermekov, M. T., Rozhkova, O. V., Smagulov, A. S. (2022). Effectiveness analysis of Maikuben brown coal combustion in the heating boiler “Kamkor-300.” Journal of Physics: Conference Series, 2211 (1), 012003. https://doi.org/10.1088/1742-6596/2211/1/012003

- ISO 7404-5. Methods for the petrographic analysis of coals – Part 5: Method of determining microscopically the reflectance of vitrinite. Available at: https://cdn.standards.iteh.ai/samples/42832/c2926e4841384667987b347a9257cf0f/ISO-7404-5-2009.pdf

- ISO 11722. Solid mineral fuels – Hard coal – Determination of moisture in the general analysis test sample by drying in nitrogen. Available at: https://cdn.standards.iteh.ai/samples/62610/8c78a84a373d499483d1e1881597bc80/ISO-11722-2013.pdf

- ISO 1171. Solid mineral fuels – Determination of ash. Available at: https://cdn.standards.iteh.ai/samples/55944/eea836eacc03443982645044ee1082a4/ISO-1171-2010.pdf

- ISO 334. Coal and coke – Determination of total sulfur – Eschka method. Available at: https://cdn.standards.iteh.ai/samples/79738/c9442640ff044268a9079c42b138803e/ISO-334-2020.pdf

- ISO 625. Solid mineral fuels – Determination of carbon and hydrogen – Liebig method. Available at: https://cdn.standards.iteh.ai/samples/4746/b111e919a77f473f9d9678f3d457f8fc/ISO-625-1996.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Almagul Mergalimova, Аlexandra Аtyaksheva, Ybray Sultan, Seitzhapparov Nursultan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.