Determination of the cellulose- and lipid-containing components influence on the extrudate technological indicators

DOI:

https://doi.org/10.15587/1729-4061.2024.301843Keywords:

vegetable extrudate, cellulose-containing components, lipid-containing components, sunflower husk, sunflower phosphatide concentrateAbstract

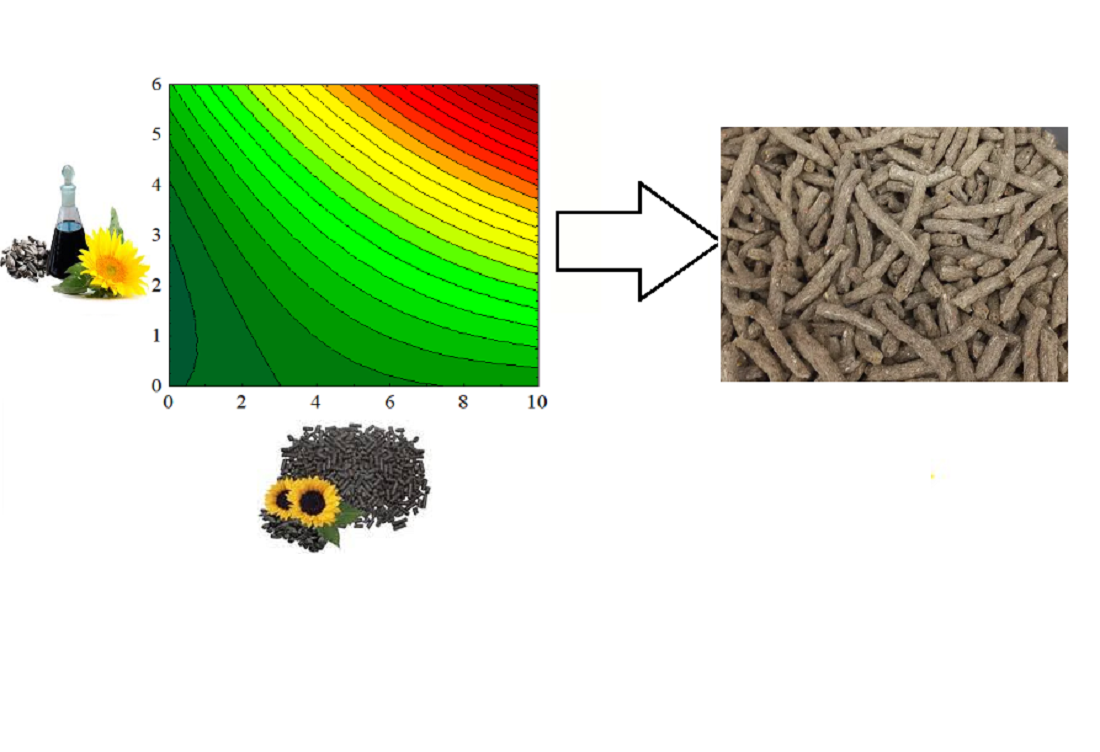

The effect of cellulose- and lipid-containing components on the technological parameters of the extruded mixture based on protein- and starch-containing raw materials on the technological parameters of the extrudate was studied. The use of components that modify such technological indicators of the extruded mixture as water resistance and swelling is substantiated. It is proposed to use sunflower husks and sunflower phosphatide concentrate as modifying additives to the mixture for extrusion. A rational ratio of the specified components in the extrudate was established to obtain indicators of water resistance in the range of 220...300 min and swelling in the range of 100...120 %. This is an important aspect of expanding the range of extruded products from the waste of oil and fat industries and obtaining high-quality competitive products.

The object of the study is the dependence of water resistance and swelling of the extruded mixture on the content of modifying additives. Their rational ratio in the extrudate is: sunflower husk – 6.0 %; sunflower phosphatide concentrate – 5.0 %. The manufactured extrudate sample corresponds to commercial fish feed in terms of chemical composition and technological parameters, and also has a 4 times lower cost. A feature of the obtained results is the possibility of regulating the water resistance, swelling and porosity of the extrudate based on protein- and starch-containing raw materials, depending on the ratio of cellulose- and lipid-containing modifying additives. This allows to change the technological parameters of the finished product depending on the chemical composition of the mixture of raw components according to the requirements of the consumer. The results of the conducted research prove that cellulose- and lipid-containing secondary products of production can be successfully transformed into new competitive products

References

- Draganovic, V., van der Goot, A. J., Boom, R., Jonkers, J. (2011). Assessment of the effects of fish meal, wheat gluten, soy protein concentrate and feed moisture on extruder system parameters and the technical quality of fish feed. Animal Feed Science and Technology, 165 (3-4), 238–250. https://doi.org/10.1016/j.anifeedsci.2011.03.004

- Banjac, V., Vukmirović, Đ., Pezo, L., Draganovic, V., Đuragić, O., Čolović, R. (2021). Impact of variability in protein content of sunflower meal on the extrusion process and physical quality of the extruded salmonid feed. Journal of Food Process Engineering, 44 (3). https://doi.org/10.1111/jfpe.13640

- Zhang, B., Liu, G., Ying, D., Sanguansri, L., Augustin, M. A. (2017). Effect of extrusion conditions on the physico-chemical properties and in vitro protein digestibility of canola meal. Food Research International, 100, 658–664. https://doi.org/10.1016/j.foodres.2017.07.060

- Sytnik, N., Kunitsa, E., Mazaeva, V., Chernukha, A., Bezuglov, O., Bogatov, O. et al. (2020). Determination of the influence of natural antioxidant concentrations on the shelf life of sunflower oil. Eastern-European Journal of Enterprise Technologies, 4 (11 (106)), 55–62. https://doi.org/10.15587/1729-4061.2020.209000

- Papchenko, V., Matveeva, T., Bochkarev, S., Belinska, A., Kunitsia, E., Chernukha, A. et al. (2020). Development of amino acid balanced food systems based on wheat flour and oilseed meal. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 66–76. https://doi.org/10.15587/1729-4061.2020.203664

- Vasenko, A., Rybalova, O., Kozlovskaya, O. (2016). A study of significant factors affecting the quality of water in the Oskil river (Ukraine). Eastern-European Journal of Enterprise Technologies, 3 (10 (81)), 48–55. https://doi.org/10.15587/1729-4061.2016.72415

- Pospelov, B., Andronov, V., Rybka, E., Krainiukov, O., Maksymenko, N., Meleshchenko, R. et al. (2020). Mathematical model of determining a risk to the human health along with the detection of hazardous states of urban atmosphere pollution based on measuring the current concentrations of pollutants. Eastern-European Journal of Enterprise Technologies, 4 (10 (106)), 37–44. https://doi.org/10.15587/1729-4061.2020.210059

- Vasyukov, A., Loboichenko, V., Bushtec, S. (2016). Identification of bottled natural waters by using direct conductometry. Ecology, Environment and Conservation, 22 (3), 1171–1176. Available at: http://repositsc.nuczu.edu.ua/handle/123456789/1633

- Loboichenko, V. M., Vasyukov, A. E., Tishakova, T. S. (2017). Investigations of Mineralization of Water Bodies on the Example of River Waters of Ukraine. Asian Journal of Water, Environment and Pollution, 14 (4), 37–41. https://doi.org/10.3233/ajw-170035

- Pospelov, B., Andronov, V., Rybka, E., Krainiukov, O., Karpets, K., Pirohov, O. et al. (2019). Development of the correlation method for operative detection of recurrent states. Eastern-European Journal of Enterprise Technologies, 6 (4 (102)), 39–46. https://doi.org/10.15587/1729-4061.2019.187252

- Pospelov, B., Rybka, E., Togobytska, V., Meleshchenko, R., Danchenko, Y., Butenko, T. et al. (2019). Construction of the method for semi-adaptive threshold scaling transformation when computing recurrent plots. Eastern-European Journal of Enterprise Technologies, 4 (10 (100)), 22–29. https://doi.org/10.15587/1729-4061.2019.176579

- Sytnik, N., Kunitsia, E., Mazaeva, V., Chernukha, A., Kovalov, P., Grigorenko, N. et al. (2020). Rational parameters of waxes obtaining from oil winterization waste. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 29–35. https://doi.org/10.15587/1729-4061.2020.219602

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. https://doi.org/10.15587/1729-4061.2020.200026

- Leonard, W., Zhang, P., Ying, D., Fang, Z. (2019). Application of extrusion technology in plant food processing byproducts: An overview. Comprehensive Reviews in Food Science and Food Safety, 19 (1), 218–246. https://doi.org/10.1111/1541-4337.12514

- Bajaj, S. R., Singhal, R. S. (2019). Effect of extrusion processing and hydrocolloids on the stability of added vitamin B12 and physico-functional properties of the fortified puffed extrudates. LWT, 101, 32–39. https://doi.org/10.1016/j.lwt.2018.11.011

- Yousf, N., Nazir, F., Salim, R. (2017). Water solubility index and water absorption index of extruded product from rice and carrot blend. Journal of Pharmacognosy and Phytochemistry, 6 (6), 2165–2168. Available at: http://surl.li/rqalu

- de Oliveira, F. C., Coimbra, J. S. dos R., de Oliveira, E. B., Zuñiga, A. D. G., Rojas, E. E. G. (2014). Food Protein-polysaccharide Conjugates Obtained via the Maillard Reaction: A Review. Critical Reviews in Food Science and Nutrition, 56 (7), 1108–1125. https://doi.org/10.1080/10408398.2012.755669

- Beck, S. M., Knoerzer, K., Arcot, J. (2017). Effect of low moisture extrusion on a pea protein isolate’s expansion, solubility, molecular weight distribution and secondary structure as determined by Fourier Transform Infrared Spectroscopy (FTIR). Journal of Food Engineering, 214, 166–174. https://doi.org/10.1016/j.jfoodeng.2017.06.037

- Rahman, M. A. U., Rehman, A., Chuanqi, X. et al. (2015). Extrusion of feed/feed ingredients and its effect on digestibility and performance of poultry: A review. International Journal of Current Microbiology and Applied Sciences, 4 (4), 48–61. Available at: http://surl.li/rqamn

- Belinska, A., Bochkarev, S., Varankina, O., Rudniev, V., Zviahintseva, O., Rudnieva, K. et al. (2019). Research on oxidative stability of protein-fat mixture based on sesame and flax seeds for use in halva technology. Eastern-European Journal of Enterprise Technologies, 5 (11 (101)), 6–14. https://doi.org/10.15587/1729-4061.2019.178908

- Belinska, A., Bliznjuk, O., Shcherbak, O., Masalitina, N., Myronenko, L., Varankina, O. et al. (2022). Improvement of fatty systems biotechnological interesterification with immobilized enzyme preparation usage. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 6–13. https://doi.org/10.15587/1729-4061.2022.268373

- Román, L., Martínez, M. M., Gómez, M. (2015). Assessing of the potential of extruded flour paste as fat replacer in O/W emulsion: A rheological and microstructural study. Food Research International, 74, 72–79. https://doi.org/10.1016/j.foodres.2015.04.035

- Wang, P., Fu, Y., Wang, L., Saleh, A. S. M., Cao, H., Xiao, Z. (2017). Effect of enrichment with stabilized rice bran and extrusion process on gelatinization and retrogradation properties of rice starch. Starch - Stärke, 69 (7-8). https://doi.org/10.1002/star.201600201

- Garcia-Amezquita, L. E., Tejada-Ortigoza, V., Serna-Saldivar, S. O., Welti-Chanes, J. (2018). Dietary Fiber Concentrates from Fruit and Vegetable By-products: Processing, Modification, and Application as Functional Ingredients. Food and Bioprocess Technology, 11 (8), 1439–1463. https://doi.org/10.1007/s11947-018-2117-2

- Rashid, S., Rakha, A., Anjum, F. M., Ahmed, W., Sohail, M. (2015). Effects of extrusion cooking on the dietary fibre content and Water Solubility Index of wheat bran extrudates. International Journal of Food Science & Technology, 50 (7), 1533–1537. https://doi.org/10.1111/ijfs.12798

- Mohamad Mazlan, M., Talib, R. A., Mail, N. F., Taip, F. S., Chin, N. L., Sulaiman, R. et al. (2019). Effects of extrusion variables on corn-mango peel extrudates properties, torque and moisture loss. International Journal of Food Properties, 22 (1), 54–70. https://doi.org/10.1080/10942912.2019.1568458

- Abilmazhinov, Y., Bekeshova, G., Nesterenko, A., Dibrova, Z., Ermolaev, V., Ponomarev, E., Vlasova, V. (2023). A Review on The Improvement of Extruded Food Processing Equipment: Extrusion Cooking in Food Processing. Food Science and Technology, 43. https://doi.org/10.5327/fst.80621

- Ruiz-Gutiérrez, M. G., Sánchez-Madrigal, M. Á., Quintero-Ramos, A. (2018). The Extrusion Cooking Process for the Development of Functional Foods. Extrusion of Metals, Polymers and Food Products. https://doi.org/10.5772/intechopen.68741

- Babatunde, O. O., Cargo-Froom, C. L., Ai, Y., Newkirk, R. W., Marinangeli, C. P. F., Shoveller, A. K., Columbus, D. A. (2023). Extrusion effects on the starch and fibre composition of Canadian pulses. Canadian Journal of Animal Science, 103 (3), 289–297. https://doi.org/10.1139/cjas-2022-0127

- Petik, I., Litvinenko, O., Kalyna, V., Ilinska, O., Raiko, V., Filenko, O. et al. (2023). Development of extruded animal feed based on fat and oil industry waste. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 112–120. https://doi.org/10.15587/1729-4061.2023.275509

- Papchenko, V., Stepankova, G., Karatieieva, O., Balandina, I., Shapovalenko, D., Kariuk, A. et al. (2023). Determining the effect of raw materials moisture and lipid content on the technological properties of the extruded protein-fat system. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 37–46. https://doi.org/10.15587/1729-4061.2023.285132

- Ačkar, Đ., Jozinović, A., Babić, J., Miličević, B., Panak Balentić, J., Šubarić, D. (2018). Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innovative Food Science & Emerging Technologies, 47, 517–524. https://doi.org/10.1016/j.ifset.2018.05.004

- Makowska, A., Zielińska‐Dawidziak, M., Niedzielski, P., Michalak, M. (2017). Effect of extrusion conditions on iron stability and physical and textural properties of corn snacks enriched with soybean ferritin. International Journal of Food Science & Technology, 53 (2), 296–303. https://doi.org/10.1111/ijfs.13585

- Korm dlia ryb ekstrudovanyi Roicher Akva Korop Finishnyi 6,5-8,5 mm. Available at: http://surl.li/rglcp

- Phosphatide concentrate (sunflower, rapeseed). Available at: http://surl.li/rhmkf

- Sunflower husk pellets. Available at: http://surl.li/rhmkc

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ihor Petik, Olena Litvinenko, Serhii Stankevych, Inna Zabrodina, Maryna Ponomarova, Oleh Kotliar, Ruslan Kliuchko, Oleksii Myhalenko, Tetiana Pidpala, Galyna Danylchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.