Identifying patterns in loading a gondola car body with reinforcing belts in the structure of side walls

DOI:

https://doi.org/10.15587/1729-4061.2024.303987Keywords:

transport mechanics, gondola car improvement, gondola car frame, body load, body strengthAbstract

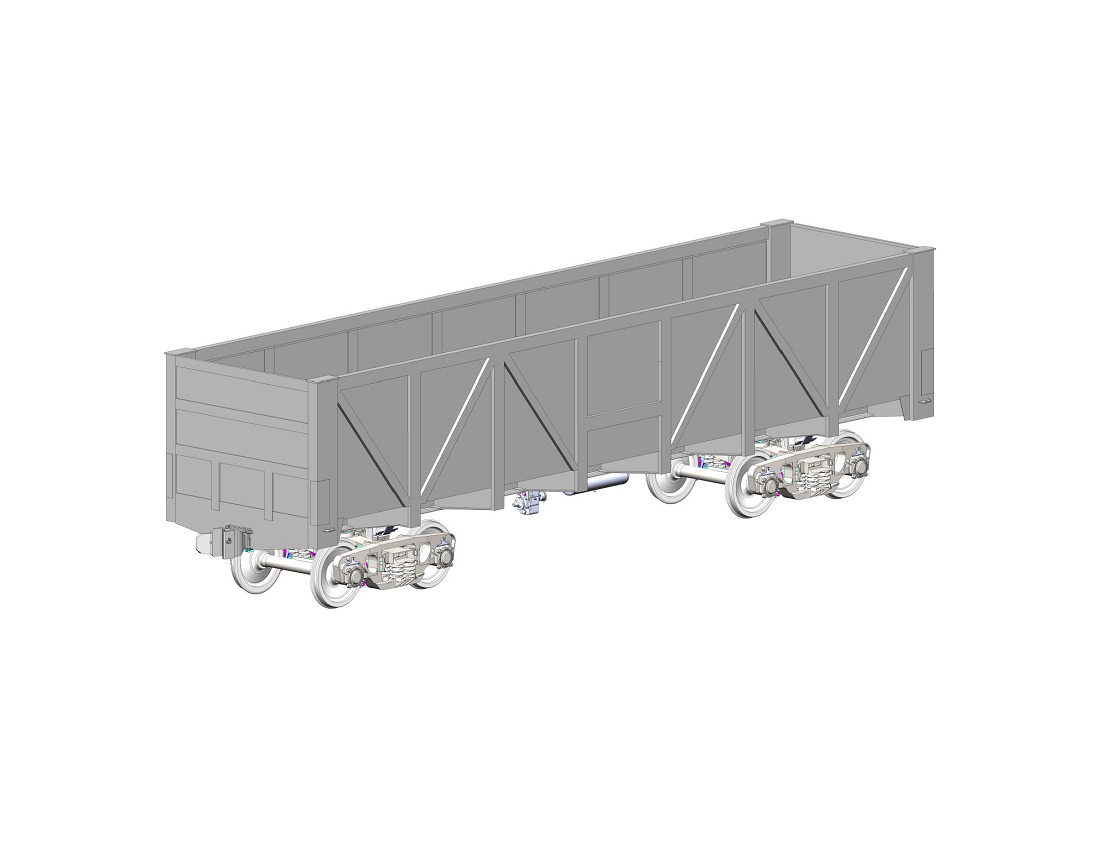

The object of this study is the processes of occurrence, perception, and redistribution of loads in the body of a gondola car with reinforcing belts in the structure of side walls.

In order to improve the strength of side walls of the gondola car body, it is proposed to strengthen them with additional belts. At the same time, it is reinforced with diagonal belts in three sections of the body on the side of the consoles, and in the middle section, 1/3 of the height from the lower strapping, with a horizontal belt. To determine the parameters for the execution of profiles in the reinforcing belts, the calculation of the gondola car body as a rod system was carried out. Based on the resulting values of bending moments, the moment of resistance of the cross-section of the profiles of the reinforcing belts was determined. The calculation of the strength of the body of the gondola car under the main modes of its loads in operation (I and III calculation modes) was carried out. It was found that the resulting stresses were 10.3 % lower than those occurring in a typical design of a gondola car body. The movement of the gondola car in the empty and loaded states was evaluated.

A feature of the reported research results is that the improvement of the strength of the side walls of the gondola car body is achieved by increasing the rigidity of its frame.

The field of practical use of the results is the engineering industry, in particular, railroad transport. The conditions for the practical application of results are the symmetrical distribution of reinforcing belts along the length of the gondola car body.

This study results may contribute to improving the durability of gondola car bodies in operation, and accordingly to reducing costs for unscheduled repairs. Also, the findings could prove useful for designing modern structures of railroad cars

References

- Čižiūnienė, K., Matijošius, J., Sokolovskij, E., Balevičiūtė, J. (2024). Assessment of Implementing Green Logistics Principles in Railway Transport: The Case of Lithuania. Sustainability, 16 (7), 2716. https://doi.org/10.3390/su16072716

- Dižo, J. (2016). Analysis of a Goods Wagon Running on a Railway Test Track. Manufacturing Technology, 16 (4), 667–672. https://doi.org/10.21062/ujep/x.2016/a/1213-2489/mt/16/4/667

- Soukup, J., Skočilas, J., Skočilasová, B., Dižo, J. (2017). Vertical Vibration of Two Axle Railway Vehicle. Procedia Engineering, 177, 25–32. https://doi.org/10.1016/j.proeng.2017.02.178

- Li, J., Pang, Z., Liu, X., Niu, N., Zhang, B. (2024). A Study on a Solution for Standardization Work for the Sustainable Development of Railway Enterprises. Sustainability, 16 (6), 2564. https://doi.org/10.3390/su16062564

- Sharma, V., Zivic, F., Adamovic, D., Ljusic, P., Kotorcevic, N., Slavkovic, V., Grujovic, N. (2022). Multi-Criteria Decision Making Methods for Selection of Lightweight Material for Railway Vehicles. Materials, 16 (1), 368. https://doi.org/10.3390/ma16010368

- Vatulia, G., Lovska, A., Myamlin, S., Rybin, A., Nerubatskyi, V., Hordiienko, D. (2023). Determining patterns in loading the body of a gondola with side wall cladding made from corrugated sheets under operating modes. Eastern-European Journal of Enterprise Technologies, 2 (7 (122)), 6–14. https://doi.org/10.15587/1729-4061.2023.275547

- Kondratiev, A., Píštěk, V., Smovziuk, L., Shevtsova, M., Fomina, A., Kučera, P. (2021). Stress–Strain Behaviour of Reparable Composite Panel with Step-Variable Thickness. Polymers, 13 (21), 3830. https://doi.org/10.3390/polym13213830

- Dveirin, O. Z., Andreev, O. V., Kondrat’ev, A. V., Haidachuk, V. Ye. (2021). Stressed State in the Vicinity of a Hole in Mechanical Joint of Composite Parts. International Applied Mechanics, 57 (2), 234–247. https://doi.org/10.1007/s10778-021-01076-4

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. https://doi.org/10.1177/0954409715593971

- Pravilonis, T., Sokolovskij, E. (2020). Analysis of composite material properties and their possibilities to use them in bus frame construction. Transport, 35 (4), 368–378. https://doi.org/10.3846/transport.2020.13018

- Galimova, F., Khurmatov, Y., Abdulloev, M., Jumabekov, B., Sultonaliev, D., Ergeshova, D. (2021). Modern Gondola with Lightweight Body. Lecture Notes in Networks and Systems, 1043–1050. https://doi.org/10.1007/978-3-030-80946-1_94

- Patrascu, A. I., Hadar, A., Pastrama, S. D. (2019). Structural Analysis of a Freight Wagon with Composite Walls. Materiale Plastice, 57 (2), 140–151. https://doi.org/10.37358/mp.20.2.5360

- Płaczek, M., Wróbel, A., Olesiejuk, M. (2017). Modelling and arrangement of composite panels in modernized freight cars. MATEC Web of Conferences, 112, 06022. https://doi.org/10.1051/matecconf/201711206022

- Panchenko, S., Gerlici, J., Lovska, A., Vatulia, G., Rybin, A. (2024). Determination of the transverse load of the box wagon body with sandwich panel walls. 15th International Scientific Conference on Aeronautics, Automotive, and Railway Engineering And Technologies (BulTrans-2023). https://doi.org/10.1063/5.0201453

- Baier, A., Majzner, M. (2012). Application of feature based method in constructing innovative sheathing of railway wagons. Journal of Achievements in Materials and Manufacturing Engineering, 52 (2), 91–98. Available at: https://delibra.bg.polsl.pl/dlibra/doccontent?id=32231

- Olmos Irikovich, Z., Rustam Vyacheslavovich, R., Mahmod Lafta, W., Yadgor Ozodovich, R. (2020). Development of new polymer composite materials for the flooring of rail carriage. International Journal of Engineering & Technology, 9 (2), 378–381. https://doi.org/10.14419/ijet.v9i2.30519

- Liu, W., Zhang, L., Bi, C., Huo, Y., Zhang, R., Wang, Z. (2022). The Anti-Fatigue Design of 80 t Depressed-Center Gondola Car Body. Processes, 10 (8), 1618. https://doi.org/10.3390/pr10081618

- Dovbush, T. A., Khomyk, N. I., Babii, A. V., Tson, H. B., Dovbush, A. D. (2022). Opir materialiv. Ternopil: FOP Palianytsia V.A., 220. Available at: https://elartu.tntu.edu.ua/handle/lib/37778

- Barabash, M. S., Soroka, M. M., Surianinov, M. H. (2018). Neliniyna budivelna mekhanika z PK Lira – SAPR. Odesa: Ekolohiya, 248.

- Dižo, J., Blatnický, M., Steišūnas, S., Skočilasová, B. (2018). Assessment of a rail vehicle running with the damaged wheel on a ride comfort for passengers. MATEC Web of Conferences, 157, 03004. https://doi.org/10.1051/matecconf/201815703004

- Lovskaya, A. (2015). Computer simulation of wagon body bearing structure dynamics during transportation by train ferry. Eastern-European Journal of Enterprise Technologies, 3 (7 (75)), 9–14. https://doi.org/10.15587/1729-4061.2015.43749

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252. Available at: https://ep3.nuwm.edu.ua/22175/1/Комп%27ютерна%20графіка.pdf

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172. Available at: https://lib.lntu.edu.ua/sites/default/files/2021-02/Інженерна%20графіка%20в%20SolidWorks.pdf

- Domin, Yu. V., Cherniak, H. Yu. (2003). Osnovy dynamiky vahoniv. Kyiv: KUETT, 269.

- Bohach I. V., Krakovetskyi O. Yu., Kylyk L. V. (2020). Chyselni metody rozviazannia dyferentsialnykh rivnian zasobamy MathCad. Vinnytsia, 106. Available at: http://pdf.lib.vntu.edu.ua/books/IRVC/Bogach_2020_106.pdf

- Siasiev, A. V. (2004). Vstup do systemy MathCad. Dnipropetrovsk, 108. Available at: https://static.klasnaocinka.com.ua/uploads/editor/8959/536928/sitepage_51/files/mathcad_sayt.pdf

- Gerlici, J., Lovska, A., Vatulia, G., Pavliuchenkov, M., Kravchenko, O., Solčanský, S. (2023). Situational Adaptation of the Open Wagon Body to Container Transportation. Applied Sciences, 13 (15), 8605. https://doi.org/10.3390/app13158605

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Rybin, A., Kravchenko, O. (2023). Strength Assessment of an Improved Design of a Tank Container under Operating Conditions. Communications - Scientific Letters of the University of Zilina, 25 (3), B186–B193. https://doi.org/10.26552/com.c.2023.047

- Lovskaya, A. (2014). Assessment of dynamic efforts to bodies of wagons at transportation with railway ferries. Eastern-European Journal of Enterprise Technologies, 3 (4 (69)), 36–41. https://doi.org/10.15587/1729-4061.2014.24997

- Caban, J., Nieoczym, A., Gardyński, L. (2021). Strength analysis of a container semi-truck frame. Engineering Failure Analysis, 127, 105487. https://doi.org/10.1016/j.engfailanal.2021.105487

- Lovska, A. (2018). Simulation of Loads on the Carrying Structure of an Articulated Flat Car in Combined Transportation. International Journal of Engineering & Technology, 7 (4.3), 140. https://doi.org/10.14419/ijet.v7i4.3.19724

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Alyona Lovska, Oleksandr Stanovskyi, Oksana Zharovа, Yevheniia Naumenko, Yevhen Pelypenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.