Justification of parameters of impact-spreading finger shaft for grinder-mixer-dryer using the example of eggshells

DOI:

https://doi.org/10.15587/1729-4061.2024.304127Keywords:

grinder-mixer-dryer, impact-spreading finger shaft, cracks, destructive speed, eggshellAbstract

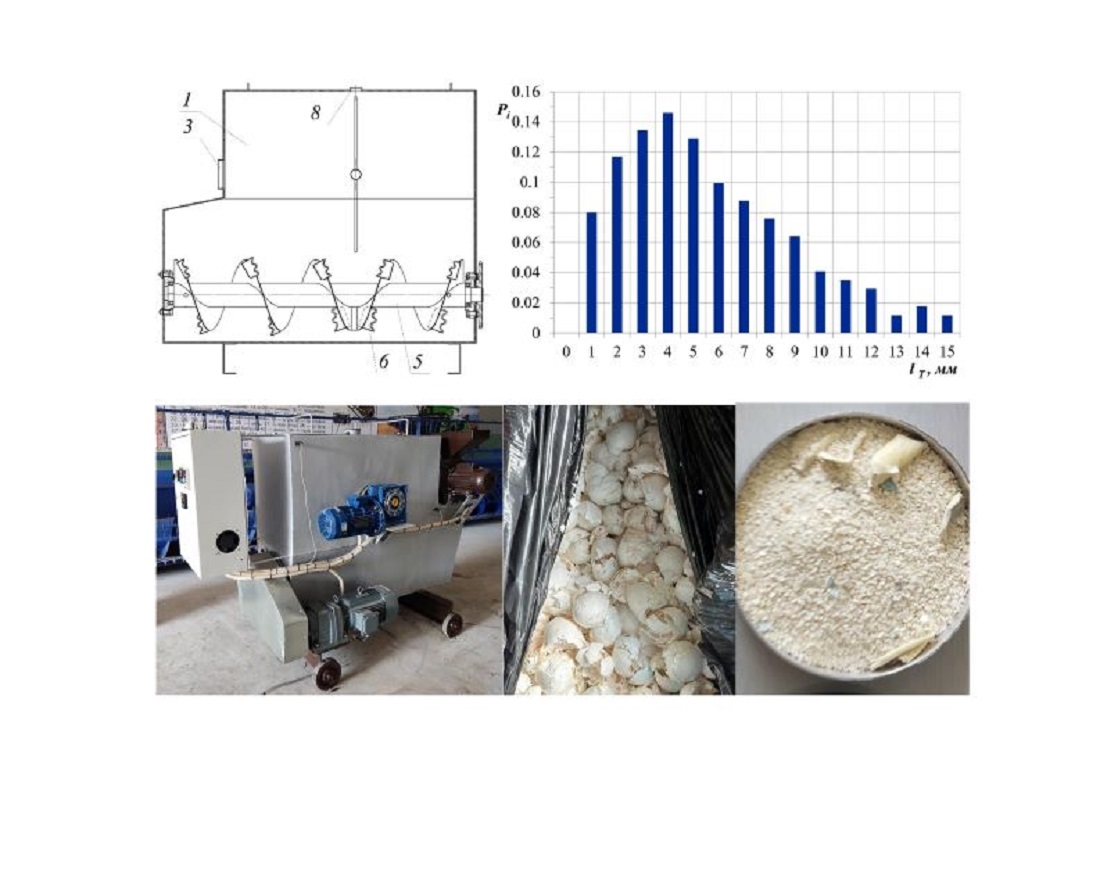

The object of the study is to determine the critical impact speed during shell destruction, study crack formation in the shell, and grind the shell. When operating a grinder-mixer-dryer, problems arise such as determining the speed of impact on the shell depending on the height of its fall, the lack of ability to determine the speed of shell fall from certain heights, which complicates planning the operation of the finger shaft. As a result of research, it was found that an auger with knives crushes and moves feed raw materials, and the impact-spreading shaft ensures partial grinding of fragile raw materials and intensive processes of mixing and drying wet feed with uniform filling of the installation hopper. The appearance of cracks on the shell when it falls from a height of 0.15 m has been experimentally recorded. Therefore, this speed of impact of the shell on a metal surface is the critical peripheral speed of the impact-spreading shaft, which ensures partial crushing of the shell. As a result of theoretical studies, an analytical expression was obtained that provides the determination of the shell impact speed depending on the height of its fall. The value of the critical peripheral speed of the fingers of the impact-spreading shaft is determined to be 1.66 m/s. The experimental results showed the effective occurrence of grinding, mixing and drying processes. Moreover, within 15 minutes of operation of the installation, the wet shell was crushed in accordance with the requirements. The uniformity reached up to 90 % within 4 to 6 minutes of its operation, and drying proceeded at a rate of 26.54 % per hour. All this proves the effectiveness of the processes of grinding, mixing and drying wet food, and also confirms the reliability of theoretical research

Supporting Agency

- This research has been/was/is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP19679802).

References

- Laohavisuti, N., Boonchom, B., Boonmee, W., Chaiseeda, K., Seesanong, S. (2021). Simple recycling of biowaste eggshells to various calcium phosphates for specific industries. Scientific Reports, 11 (1). https://doi.org/10.1038/s41598-021-94643-1

- Qiu, Y., Hou, Y., Zhang, S., Jin, L., Zhou, J., Chen, J. (2022). Study on the preparation and properties of CaCO3 ultrafine powder derived from waste eggshell. Environmental Technology, 1–10. https://doi.org/10.1080/09593330.2022.2141664

- Liu, H., Guo, X., Yin, Y., Song, Sh., Liu, M., He, H. (2023). Optimization of Separation Process of Eggshell and Shell Membrane. Science and Technology of Food Industry, 44 (12), 193–200. https://doi.org/10.13386/j.issn1002-0306.2020090076

- Ahmed, T. A. E., Younes, M., Wu, L., Hincke, M. T. (2021). A Survey of Recent Patents in Engineering Technology for the Screening, Separation and Processing of Eggshell. Frontiers in Bioengineering and Biotechnology, 9. https://doi.org/10.3389/fbioe.2021.677559

- Markochev, V. M. (2011). Reologicheskaya model' razrushayushchegosya tverdogo tela. Zavodskaya laboratoriya. Diagnostika materialov, 6, 44–47.

- Markochev, V. M., Alymov, M. I. (2017). On The Brittle Fracture Theory By Ya. Frenkel And A. Griffith. Chebyshevskii Sbornik, 18 (3), 381–393. https://doi.org/10.22405/2226-8383-2017-18-3-381-393

- Kochetkov, A. V., Fedotov, P. V. (2013). Nekotorye voprosy teorii udara. Naukovedeniye, 5, 1–15.

- Wang, D. K., Sun, L. T., Wei, J. P. (2019). Microstructure Evolution and Fracturing Mechanism of Coal Under Thermal Shock. Rock and Soil Mechanics, 40 (2), 529.

- Kachayev, A. Ye. (2011). K opredeleniyu vremeni udara i moshchnosti dezintegratora, raskhoduyemoy na izmel'cheniye pri udarnom vozdeystvii. Vestnik Belgorodskogo gosudarstvennogo tekhnologicheskogo universiteta imeni Shukhova, 3, 1–5.

- Glebov, L. A., Demskiy, A. B., Veden'yev, V. F., Yablokov, A. Ye. (2010). Tekhnologicheskoye oborudovaniye i potochnye linii predpriyatiy po pererabotke zerna. Moscow: DeLi print, 696.

- Maudlin, T. (2011). How bell reasoned: A reply to Griffiths. American Journal of Physics, 79 (9), 966–970. https://doi.org/10.1119/1.3606476

- Iskakov, R. M., Mamirbaeva, I. K., Gulyarenko, A. A., Silaev, M. Yu., Gusev, A. S. (2022). Improved Hammers for Crushers in Feed Production. Russian Engineering Research, 42 (10), 987–992. https://doi.org/10.3103/s1068798x22100124

- Smits, M., Kronbergs, E. (2017). Determination center of percussion for hammer mill hammers. Engineering for Rural Development. https://doi.org/10.22616/erdev2017.16.n072

- Kupchuk, I. M., Solona, O. V., Derevenko, I. A., Tverdokhlib, I. V. (2018). Verification of the Mathematical Model of the Energy Consumption Drive for Vibrating Disc Crusher. Inmateh-Agricultural Engineering, 55 (2), 113–120. Available at: https://www.researchgate.net/publication/328293822_Verification_of_the_mathematical_model_of_the_energy_consumption_drive_for_vibrating_disc_crusher

- Abilzhanuly, T., Iskakov, R., Abilzhanov, D., Darkhan, O. (2023). Determination of the average size of preliminary grinded wet feed particles in hammer grinders. Eastern-European Journal of Enterprise Technologies, 1 (1 (121)), 34–43. https://doi.org/10.15587/1729-4061.2023.268519

- Tian, H., Wang, H., Huang, T., Wang, D., Liu, F., Han, B. (2018). Design of Combination Sieve for Hammer Feed Mill to Improve Crushing Performance. Transactions of the Chinese Society of Agricultural Engineering, 34 (22), 45–2. https://doi.org/10.11975/j.issn.1002-6819.2018.22.006

- Verma, H. R., Singh, K. K., Basha, S. M. (2018). Effect of Milling Parameters on the Concentration of Copper Content of Hammer-Milled Waste PCBs: A Case Study. Journal of Sustainable Metallurgy, 4 (2), 187–193. https://doi.org/10.1007/s40831-018-0179-z

- Feng, F., Shi, J., Yang, J., Ma, J. (2022). Correlation between the Angle of the Guide Plate and Crushing Performance in Vertical Shaft Crushers. Shock and Vibration, 2022, 1–8. https://doi.org/10.1155/2022/9991855

- Munkhbayar, B., Bayaraa, N., Rehman, H., Kim, J., Chung, H., Jeong, H. (2012). Grinding characteristic of multi-walled carbon nanotubes-alumina composite particle. Journal of Wuhan University of Technology-Mater. Sci. Ed., 27 (6), 1009–1013. https://doi.org/10.1007/s11595-012-0590-4

- Hong, S., Kim, S. (2017). Analysis of simulation result by digital filtering technique and improvement of hammer crusher. International Journal of Mineral Processing, 169, 168–175. https://doi.org/10.1016/j.minpro.2017.11.004

- Iskakov, R. M., Iskakova, A. M., Nurushev, M. Z., Khaimuldinova, A. K., Karbayev, N. K. (2021). Method for the Production of Fat from Raw Materials and Animal Waste. Journal of Pure and Applied Microbiology, 15 (2), 716–724. https://doi.org/10.22207/jpam.15.2.23

- Iskakov, R., Sugirbay, A. (2023). Technologies for the Rational Use of Animal Waste: A Review. Sustainability, 15 (3), 2278. https://doi.org/10.3390/su15032278

- Al-Khasawneh, Y. (2021). Development and testing of a novel mathematical-physical model for the design of ring armor for the vertical shaft impact crushers. Minerals Engineering, 170, 106994. https://doi.org/10.1016/j.mineng.2021.106994

- Tumanov, A. M., Tumanova, M. I., Brusentsov, A. S. (2018). Obzor tekhniki, primenyayemoy dlya prigotovleniya kormov pri otkarmlivanii bychkov v malykh formakh khozyaystvovaniya. Izvestiya Orenburgskogo gosudarstvennogo agrarnogo universiteta, 6, 117–121. Available at: https://e.lanbook.ru/journal/issue/309771

- Kormotsekhi na kolesakh KIS-8, KIS-9, KIS-10. Prospekt. Novosibirskiy opytno-eksperimental'niy zavod nestandartnogo oborudovaniya.

- Gishchenko, M. A., Braginets, S. V., Klimenko, V. I. (2010). Kombinirovannaya mashina dlya prigotovleniya i razdachi kormov. Sel'skiy mekhanizator, 11, 22–23.

- Madyshev, I. Sh., Faizrahmanov, R. N., Kamaldinov, I. N. (2017). Efficiency of feed additives in animals. Uchenye zapiski Kazanskoy gosudarstvennoy akademii veterinarnoy meditsiny im. N.E. Baumana, 232 (4), 105–108. Available at: https://sciup.org/jeffektivnost-kormovyh-dobavok-v-zhivotnovodstve-142212948

- Nikiforov, V. Ye., Uglin, V. K., Nikitin, L. A. (2018). Tekhnologicheskaya liniya sushki semyan kormovykh trav dlya usloviy Severo-Zapada Rossii. Agrozootekhnika, 2 (1), 1–9.

- Zykov, A. V., Zakharov, A. M., Yunin, V. A. (2019). Infrared Method for Drying Vegetable Raw Materials. Journal of Advanced Research in Technical Science, 16, 107–110. https://doi.org/10.26160/2474-5901-2019-16-107-110

- Yunin, V. A., Zykov, A. V., Zakharov, A. M., Perekopsky, A. N. (2020). Research of drum installation of drum type with infrared heat source. International Research Journal, 6 (96), 64–68. Available at: https://research-journal.org/wp-content/uploads/2020/06/6-1-96.pdf#page=64

- Targ, S. M. (2010). Kratkiy kurs teoreticheskoy mekhaniki. Moscow: Vysshaya shkola, 416.

- Strelkov, S. P. (1975). Mekhanika. Moscow: Nauka, 560.

- Abilzhanov, D. T., Adil'sheyev, A. S., Shabikova, G. A. (2019). Obosnovaniye parametrov podbrasyvayushchego barabana separatora listovoy chasti trav. Vestnik Kyrgyzsko-Rossiyskogo Slavyanskogo universiteta, 19 (12), 65–71.

- Abilzhanuly, T., Iskakov, R., Issenov, S., Kubentaeva, G., Mamyrbayeva, I., Abilzhanov, D. et al. (2023). Development of a layer leveling technology that reduces the energy intensity of the processes of mixing and drying the fodder mass. Eastern-European Journal of Enterprise Technologies, 4 (7 (124)), 106–115. https://doi.org/10.15587/1729-4061.2023.286325

- Abilzhanuly, T. (2007) Kormoprigotovitel'niye mashiny dlya krest'yanskikh khozyaystv i drugikh agroformirovaniy. Astana: Kazakhskiy agrotekhnicheskiy universitet imeni Seyfullina, 200.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Tokhtar Abilzhanuly, Ruslan Iskakov, Daniyar Abilzhanov, Alexandr Gulyarenko, Valery Khan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.