Determining the influence of compaction methods on the physical-mechanical properties of asphalt concrete samples

DOI:

https://doi.org/10.15587/1729-4061.2024.304807Keywords:

compaction method, rutting resistance, compressive strength, void content, water saturation of asphalt concreteAbstract

The object of this study is the compaction methods of asphalt mixtures under laboratory conditions.

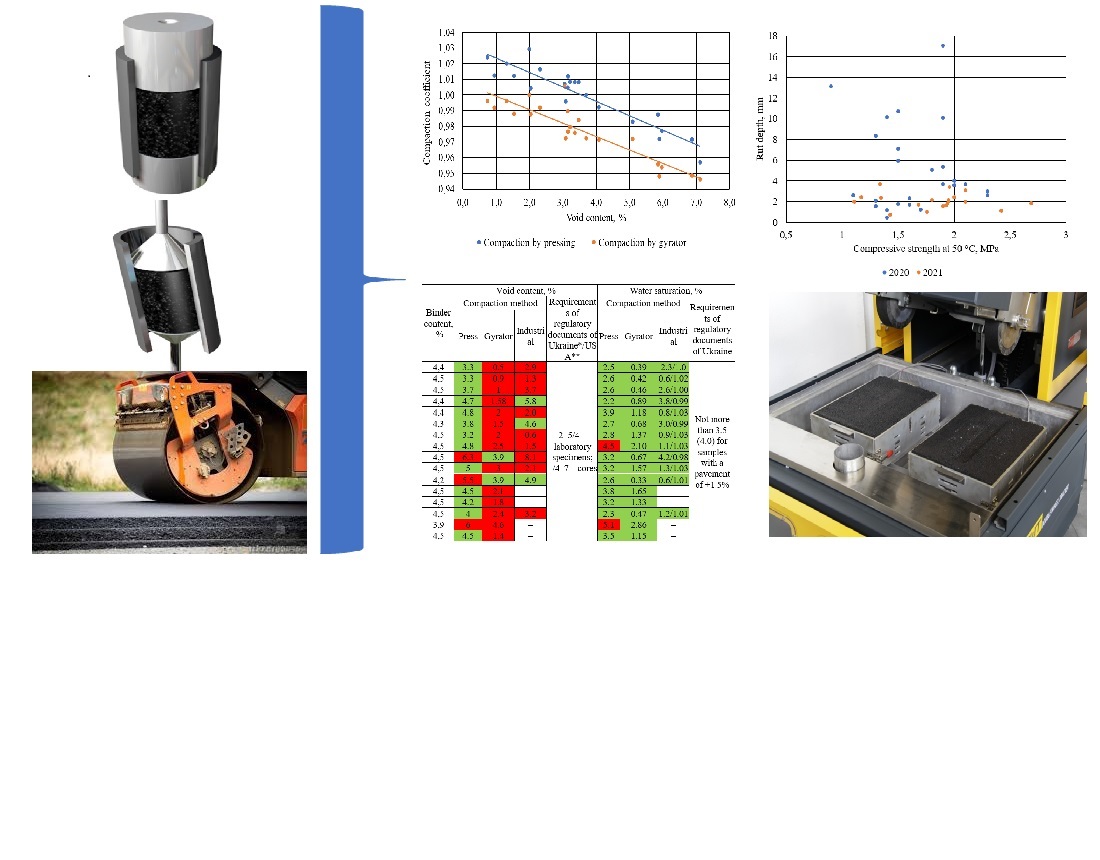

The experience of determining the physical properties of coarse-grained asphalt concretes taken from the layers of the road pavement structure shows that their values do not correspond to those of the samples obtained by laboratory compaction using the pressing method. In 90 % of cases, the density of cores exceeds the density of laboratory samples while the indicators of void content and water saturation are significantly lower than for laboratory samples. The compressive strength indicators of asphalt concrete are almost independent of compaction methods and are not very informative. All of the above leads to the conclusion that the methods of laboratory compaction by pressing do not meet modern requirements.

Low values of water saturation and void content of cores and laboratory samples compacted with a gyrator allow us to argue about outdated approaches to the design of grain compositions of asphalt concrete. Low-informative indicators of compressive strength indicate the need to use other mechanical characteristics that will make it possible to predict the properties of asphalt concrete in the pavement, for example, rutting resistance. As a summary, template solutions in the design of asphalt concrete warehouses and physical and mechanical characteristics are necessary only to establish compliance with the requirements of regulatory documents.

The current work shows that it is almost impossible to predict the properties of asphalt concrete based on laboratory samples obtained by pressing.

All this leads to the need to change the regulatory framework, which is possible by using regulatory documents of the countries in the European Union and the United States of America

References

- Hu, W., Jia, X., Huang, B., Park, H. (2017). Evaluation of compactability of asphalt mixture utilizing asphalt vibratory compactor. Construction and Building Materials, 139, 419–429. https://doi.org/10.1016/j.conbuildmat.2017.02.070

- Tarefder, R. A., Ahmad, M. (2016). Effect of compaction procedure on air void structure of asphalt concrete. Measurement, 90, 151–157. https://doi.org/10.1016/j.measurement.2016.04.054

- Huber, G. History of asphalt mix design in North America, Part 1. Available at: http://asphaltmagazine.com/history-of-asphalt-mix-design-in-north-america-part-1/

- EN 12697-30:2018. Bituminous mixtures - Test methods - Part 30: Specimen preparation by impact compactor. Available at: https://standards.iteh.ai/catalog/standards/cen/9728dcfe-4137-454b-8765-63a37932df62/en-12697-30-2018

- ASTM D6926-04. Standard Practice for Preparation of Bituminous Specimens using Marshall Apparatus.

- Duriez, M., Arrambide, J. (1964). Nouveaux traite des materiaux des constructions. Vol. 3. Paris: Dunod, 1543.

- Zhdaniuk, V., Volovyk, O., Kostin, D., Lisovin, S. (2021). An investigation of the effect of thermoplastic additives in asphalt concrete mixtures on the properties of different types of asphalt concrete. Eastern-European Journal of Enterprise Technologies, 2 (6 (110)), 61–70. https://doi.org/10.15587/1729-4061.2021.227806

- Pyrig, Y., Galkin, A., Oksak, S., Ilin, I., Shyika, Y. (2022). Influence of Rejuvenator on the Properties of Bitumen and Asphalt Concrete. Key Engineering Materials, 938, 225–233. https://doi.org/10.4028/p-b11x6t

- Tipton, R. A. (1993). A study of California kneading compactors ability to optimise angular aggregate particle orientation and interlock of large stone asphalt mixes in Montana. Montana State University. Available at: https://studylib.net/doc/13510379/a-study-of-california-kneading-compactors-ability-to-opti

- Abo-Qudais, S., Qudah, M. (2007). Effect of compaction method on bituminous mixtures voids distribution and magnitude. Advanced Characterisation of Pavement and Soil Engineering Materials - Proceedings of the International Conference on Advanced Characterisation of Pavement and Soil Engineering Materials, 817–829. Available at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84858063707&partnerID=40&md5=40ae17f7e7e9176c66547ee641cddb97

- Harman, T., Bukowski, J. R., Moutier, F., Huber, G., McGennis, R. (2002). History and Future Challenges of Gyratory Compaction: 1939 to 2001. Transportation Research Record: Journal of the Transportation Research Board, 1789 (1), 200–207. https://doi.org/10.3141/1789-22

- Development and Performance Prediction of Idaho Superpave Mixes (2004). National Institute for Advanced Transportation Technology. Available at: https://www.webpages.uidaho.edu/niatt/research/Final_Reports/KLK464-N06-08.pdf

- Bi, Y., Huang, J., Pei, J., Zhang, J., Guo, F., Li, R. (2021). Compaction characteristics assessment of Hot-Mix asphalt mixture using Superpave gyratory compaction and Stribeck curve method. Construction and Building Materials, 285, 122874. https://doi.org/10.1016/j.conbuildmat.2021.122874

- EN 12697-31:2019. Bituminous mixtures - Test methods - Part 31: Specimen preparation by gyratory compactor. Available at: https://standards.iteh.ai/catalog/standards/cen/ab0e065c-37a0-4f6e-8f6e-e7465859eaa1/en-12697-31-2019

- Oliveira, M. F., Bessa, I. S., Vasconcelos, R. R., Vasconcelos, K. L., Bernucci, L. L. B. (2021). A new approach to laboratory roller compaction method and its influence on surface texture and permanent deformation of asphalt mixtures. International Journal of Pavement Engineering, 23 (11), 3867–3878. https://doi.org/10.1080/10298436.2021.1924377

- Doyle, J. D., Howard, I. L. (2011). Linear Asphalt Compactor. Operator’s manual. Oak Ridge National Laboratory.

- Muniandy, R., Jakarni, F. M., Hassim, S., Mahmud, A. R. (2007). Development of Criteria for Slab Compaction of Laboratory Roller Compactor (Turamesin). American Journal of Applied Sciences, 4 (11), 908–911. https://doi.org/10.3844/ajassp.2007.908.911

- Bijleveld, F. R., Miller, S. R., de Bondt, A. H., Dorée, A. G. (2015). Aligning laboratory and field compaction practices for asphalt – the influence of compaction temperature on mechanical properties. International Journal of Pavement Engineering, 17 (8), 727–740. https://doi.org/10.1080/10298436.2015.1019494

- Zhao, X., Niu, D., Zhang, P., Niu, Y., Xia, H., Liu, P. (2022). Macro-meso multiscale analysis of asphalt concrete in different laboratory compaction methods and field compaction. Construction and Building Materials, 361, 129607. https://doi.org/10.1016/j.conbuildmat.2022.129607

- EN 12697-33:2003+A1:2007. Bituminous mixtures - Test methods for hot mix asphalt - Part 33: Specimen prepared by roller compactor. Available at: https://standards.iteh.ai/catalog/standards/cen/8c67ff09-b50c-4a37-bdb5-3ac26b6fcf4a/en-12697-33-2003a1-2007

- Mozghovyi, V. V., Onyshchenko, A. M., Olkhovyi, B. Y., Oproshchenko, I. O., Kutsman, O. M., Baran, S. A., Riznichenko, O. S. (2016). The assessment of durability of asphalt pavement asphalt through the test for resistance to permanent deformation accumulation. Visnyk Natsionalnoho transportnoho universytetu, 34, 283–293. Available at: http://publications.ntu.edu.ua/visnyk/34_2016/283-293.pdf

- Zolotaryov, V., Ilin, Y., Kipnis, D., Ekimov, V. (2022). The problem of optimizing laboratory compaction of asphalt concrete mixtures. Avtoshliakhovyk Ukrayiny, 2 (270), 47–55. https://doi.org/10.33868/0365-8392-2022-2-270-47-55

- EN 12697-22:2020. Bituminous mixtures - Test methods - Part 22: Wheel tracking. Available at: https://standards.iteh.ai/catalog/standards/cen/4442b66e-a324-4503-880a-ee4342064693/en-12697-22-2020

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Serhiy Chuguyenko, Rami Hamad, Denys Kipnis, Maksym Minchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.