Devising technology for extinguishing oil tanks using compressed foam by sub-layer technique

DOI:

https://doi.org/10.15587/1729-4061.2024.305684Keywords:

compression foam, fire extinguishing of petroleum products, "sublayer" extinguishing of tanks, fires in tanksAbstract

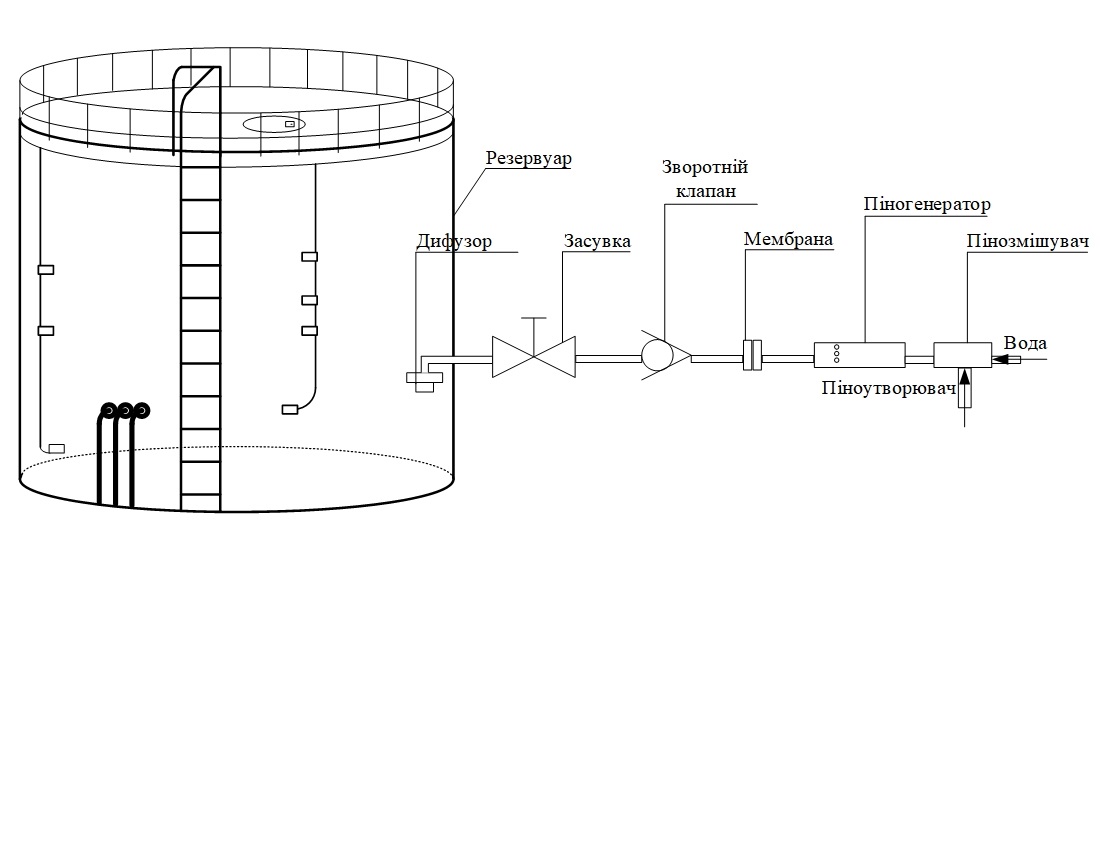

Tank facilities storing various combustible substances are a potential source of danger for the environment and human life. Fires in tanks can occur for various reasons: technical malfunctions, human factors, military operations, natural phenomena. One of the effective methods for extinguishing such fires is "sublayer" extinguishing with the help of foam of low multiplicity. The possibility of "sub-layer" extinguishing with the help of compression foam, which has unique properties, has been considered. The object of this study is the processes of stopping combustion during fire extinguishing in steel tanks for the storage of petroleum products with the use of foaming agents of increased stability, which ensure the generation of compression foam in a "sub-layer" way. A mathematical model of the movement of a submerged non-free jet of foam in the medium of motor fuel is given, which adequately describes the real physical processes that occur during "sublayer" quenching of vertical steel tanks. According to the research, it was established that the use of foam with a multiplicity of 10 (K10) is 1.56 times more effective in serving time than the use of foam with a multiplicity of 5 (K5). From an economic point of view, K10 foam also has greater advantages as the costs of the foaming agent during its generation are 3.1 times lower than when using K5 foam. The simulations demonstrated that the foaming agent consumption of the K10 foam is lower than the foaming agent consumption of the K5 foam and results in a different amount of foam coming to the surface. The simulations also showed that the volume of K5 foam increases proportionally with the feeding time, while the volume of K10 foam increases disproportionally and starts to decrease after half the time. The results from the implementation of the mathematical model were fully consistent with the results from experimental studies on extinguishing a model fire of class B

References

- Metodychni rekomendatsiyi shchodo orhanizatsiyi operatyvnykh diy pidrozdiliv DSNS pid chas hasinnia pozhezh na skladakh naftoproduktiv, shcho stalysia vnaslidok obstriliv v umovakh vedennia boiovykh diy. DSNS Ukrainy V-269 vid 23.05.2022. Available at: https://if.dsns.gov.ua/upload/1/1/9/3/3/4/7/Vr00vOSx9wVORgnKSrdVAYnz6P9sLaTd1EVLmisK.pdf

- Voitovych, T., Kovalyshyn, V., Novitskyi, Y., Voytovych, D., Pastukhov, P., Firman, V. (2020). Influence of flooded foam jets’ motion parameters on subsurface extinguishing of fires in tanks with petroleum products. Eastern-European Journal of Enterprise Technologies, 3 (10 (105)), 6–17. https://doi.org/10.15587/1729-4061.2020.206032

- Voitovych, T. M., Kovalyshyn, V. V., Chernetskyi, V. V. (2019). Design and calculation specifics of the subsurface fire extinguishing system. Fire Safety, 34, 21–27. https://doi.org/10.32447/20786662.34.2019.04

- Borovykov, V. (2015). Hasinnia pozhezh u rezervuarakh dlia zberihannia nafty ta naftoproduktiv. Pozhezhna ta tekhnohenna bezpeka, 11 (26), 28‒29.

- Korolov, R., Kovalyshyn, V., Shtajn, B. (2017). Analysis of methods for extinguishing fires in reservoirs with oil products by a combined method. ScienceRise, 6, 41–50. https://doi.org/10.15587/2313-8416.2017.104613

- Kodryk, A., Nikulin, O., Titienko, O., Kurtov, A., Shakhov, S. (2019). Dependence of compression foam properties from working parameters of foam generation process. Scientific Bulletin: Сivil Protection and Fire Safety, 1 (7), 54–63. https://doi.org/10.33269/nvcz.2019.1.54-63

- Chen, Y., Chen, T., Hu, C., Fu, X. C., Bao, Z. M., Zhang, X. Z., Xia, J. J. (2017). The research of press drop of compressed air foam flow through the bend. IOP Conference Series: Earth and Environmental Science, 81, 012118. https://doi.org/10.1088/1755-1315/81/1/012118

- Chen, Y., Chen, T., Fu, X. C., Bao, Z. M., Hu, C. (2021). The research of compressibility of compressed air foam. Journal of Physics: Conference Series, 1820 (1), 012021. https://doi.org/10.1088/1742-6596/1820/1/012021

- Su, L., Wang, L., Wang, Z., Zhang, J., Tian, Y., Yan, Y. (2012). Investigation on Compressed Air Foams Fire-extinguishing Model for Oil Pan Fire. Procedia Engineering, 45, 663–668. https://doi.org/10.1016/j.proeng.2012.08.219

- Rie, D.-H., Lee, J.-W., Kim, S. (2016). Class B Fire-Extinguishing Performance Evaluation of a Compressed Air Foam System at Different Air-to-Aqueous Foam Solution Mixing Ratios. Applied Sciences, 6 (7), 191. https://doi.org/10.3390/app6070191

- Fu, X., Bao, Z., Chen, T., Xia, J., Zhang, X., Zhang, J., Hu, Y. (2012). Application of Compressed Air Foam System in Extinguishing Oil Tank Fire and Middle Layer Effect. Procedia Engineering, 45, 669–673. https://doi.org/10.1016/j.proeng.2012.08.220

- Klius, P. P., Paliukh, V. H., Pustovoi, A. S., Senchykhin, Yu. M., Syrovoi, V. V. (1998). Pozhezhna taktyka. Kharkiv: Osnova, 592.

- Kropyvnytskyi, V. S. (Ed.) (2016). Dovidnyk kerivnyka hasinnia pozhezh. Kyiv: TOV «Litera-Druk», 320.

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172. Available at: https://lib.lntu.edu.ua/sites/default/files/2021-02/Інженерна%20графіка%20в%20SolidWorks.pdf

- Zvit pro doslidno-konstruktorsku robotu «Rozroblennia tekhnichnoho zasobu pozhezhohasinnia kompresiynoiu pinoiu ta doslidzhennia yoho kharakterystyk («pina–zasib»)». Available at: https://dsns.gov.ua/upload/1/3/2/5/0/2021-7-9-pina-zasib-rozdil-6.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vasyl Kovalyshyn, Nazarii Velykyi, Volodymyr Kovalyshyn, Tetiana Voitovych, Rostyslav Bun, Yaroslav Novitskyi, Volodymyr Firman

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.