Designing tribotechnical epoxy composite materials reinforced with chopped fibers and modified with silicon organic varnish

DOI:

https://doi.org/10.15587/1729-4061.2024.305739Keywords:

glass fibers, aramid fibers, electromagnetic field, ultrasound treatment, wear intensityAbstract

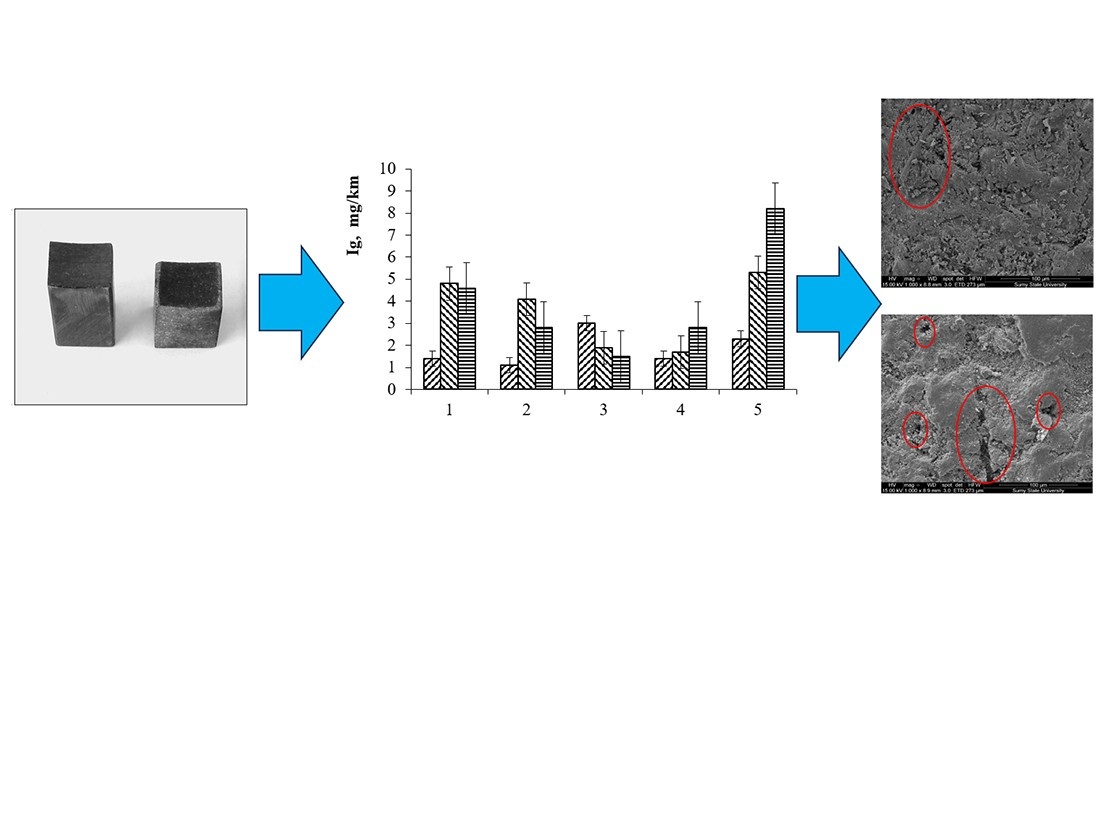

The object of research is modified epoxy composite materials containing fibrous fillers treated in physical fields. The technological features of the development of tribotechnical epoxy composites, which must withstand the effects of elevated temperatures, have been considered. In this case, it is necessary to modify the structure of the epoxy polymer matrix, which is achieved as a result of the introduction of heat-resistant organosilicon varnish. Organosilicon varnishes and chopped fibers contain technological additives, which complicates the process of structuring epoxy composites and leads to the appearance of structural defects. Removal of technological additives and cleaning the surface of the aramid and glass fibers from lubricants is possible as a result of processing the components of the composition in physical fields. There is a need to study the influence of physical fields on the structuring processes of the epoxy system and the formation of the structure of epoxy composites with specified properties. Modified epoxy composites contain chopped aramid and glass fibers treated with ultrasound. The tribotechnical characteristics of epoxy composites were studied at a sliding speed of V=1.0 m/s with a change in specific load from 0.5 MPa to 1.5 MPa. The temperature in the tribocontact zone during frictional interaction rises to 100 °C with an increase in the specific load. An increase in the density of the surface layer of tribocontact of epoxy composites with fillers treated in physical fields was revealed. The practical recommendations have been compiled for the implementation of the treatment technology of components in physical fields, which ensures structuring of epoxy composites with high tribotechnical characteristics

References

- Stawarz, S., Stawarz, M., Kucharczyk, W., Żurowski, W., Różycka, A. (2019). New Polymer Composites Including a Phenol-Formaldehyde Resin Binder Designed for Self-Lubricating Sliding Pair Elements. Advances in Science and Technology Research Journal, 13 (4), 223–229. https://doi.org/10.12913/22998624/113089

- Burmistr, M. V., Boiko, V. S., Lipko, E. O., Gerasimenko, K. O., Gomza, Yu. P., Vesnin, R. L. et al. (2014). Antifriction and Construction Materials Based on Modified Phenol-Formaldehyde Resins Reinforced with Mineral and Synthetic Fibrous Fillers. Mechanics of Composite Materials, 50 (2), 213–222. https://doi.org/10.1007/s11029-014-9408-0

- Basavaraj Pattanashetty, B., Bheemappa, S., Rajashekaraiah, H. (2017). Effect of Filler-Filler Interactions on Mechanical Properties of Phenol Formaldehyde Based Hybrid Composites. International Journal of Engineering and Technologies, 13, 24–38. https://doi.org/10.18052/www.scipress.com/ijet.13.24

- Binda, F. F., Oliveira, V. de A., Fortulan, C. A., Palhares, L. B., dos Santos, C. G. (2020). Friction elements based on phenolic resin and slate powder. Journal of Materials Research and Technology, 9 (3), 3378–3383. https://doi.org/10.1016/j.jmrt.2020.01.032

- Vinayagamoorthy, R. (2018). Friction and wear characteristics of fibre-reinforced plastic composites. Journal of Thermoplastic Composite Materials, 33 (6), 828–850. https://doi.org/10.1177/0892705718815529

- Kashytskyi, V., Sadova, O., Liushuk, O., Davydiuk, O., Myskovets, S. (2017). Examining a mechanism of generating the fragments of protective film in the trybological system "epoxycomposite–steel". Eastern-European Journal of Enterprise Technologies, 2 (11 (86)), 10–16. https://doi.org/10.15587/1729-4061.2017.97418

- Berladir, K., Zhyhylii, D., Gaponova, O., Krmela, J., Krmelová, V., Artyukhov, A. (2022). Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions. Polymers, 14 (10), 2087. https://doi.org/10.3390/polym14102087

- Panda, A., Dyadyura, K., Savchuk, P., Kashytskyi, V., Malets, V., Valicek, J. et al. (2019). The results of theoretical and experimental studies of tribotechnical purposes composites on the basis of epoxy composite material. MM Science Journal, 2019 (05), 3509–3518. https://doi.org/10.17973/mmsj.2019_12_2019032

- Stukhliak, P., Golotenko, O., Skorokhod, A. (2015). Influence of microwave electromagnetic treatment on properties of epoxy composites. Eastern-European Journal of Enterprise Technologies, 1 (5 (73)), 32–37. https://doi.org/10.15587/1729-4061.2015.36978

- Li, Z., Liu, J., Yuan, Y., Li, E., Wang, F. (2017). Effects of surface fluoride-functionalizing of glass fiber on the properties of PTFE/glass fiber microwave composites. RSC Advances, 7 (37), 22810–22817. https://doi.org/10.1039/c7ra02715j

- Coleman, J. N., Khan, U., Blau, W. J., Gun’ko, Y. K. (2006). Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon, 44 (9), 1624–1652. https://doi.org/10.1016/j.carbon.2006.02.038

- Riabchykov, M., Tsykhanovska, I., Alexandrov, A. (2023). Justification of technologies for the synthesis of mineral nanoparticles for the creation of magnetic smart textile. Journal of Materials Science, 58 (16), 7244–7256. https://doi.org/10.1007/s10853-023-08463-x

- Sabry, I., Mourad, A.-H. I., Subhan, A., Idrisi, A. H. (2022). Wear resistance of glass and carbon fibers/epoxy composites. 2022 Advances in Science and Engineering Technology International Conferences (ASET). https://doi.org/10.1109/aset53988.2022.9734885

- Savchuk, P. P., Kostornov, A. G., Kashitskii, V. P., Sadova, O. L. (2014). Friction Wear of Modified Epoxy Composites. Powder Metallurgy and Metal Ceramics, 53 (3-4), 205–209. https://doi.org/10.1007/s11106-014-9605-3

- Wang, H., Sun, A., Qi, X., Dong, Y., Fan, B. (2021). Experimental and Analytical Investigations on Tribological Properties of PTFE/AP Composites. Polymers, 13 (24), 4295. https://doi.org/10.3390/polym13244295

- Kashytskyi, V., Sadova, O., Melnychuk, M., Savchuk, P., Liushuk, O. (2022). Influence of Additives Processed by Physical Fields on Tribotechnical Properties of Polymer Composites. Advances in Design, Simulation and Manufacturing V, 393–403. https://doi.org/10.1007/978-3-031-06025-0_39

- Brailo, M., Buketov, A., Yakushchenko, S., Sapronov, O., Vynar, V., Kobelnik, O. (2018). The Investigation of Tribological Properties of Epoxy-Polyether Composite Materials for Using in the Friction Units of Means of Sea Transport. Materials Performance and Characterization, 7 (1), 20170161. https://doi.org/10.1520/mpc20170161

- Hu, X. J., Chen, Y. N., Bian, Q., Chen, M., Qin, W., Feng, J. (2014). Preparation and Properties of Organosilicon-Modified Epoxy Esters Resin. Advanced Materials Research, 960-961, 148–151. https://doi.org/10.4028/www.scientific.net/amr.960-961.148

- Brailo, M. V., Yakushchenko, S. Y. (2021). Development of epoxy-polyester base modified with UV light for upgrading of technological equipment of vehicles. Journal of Hydrocarbon Power Engineering, 8 (1), 33–39. Available at: http://elar.nung.edu.ua/handle/123456789/9217

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vitalii Kashytskyi, Oksana Sadova, Valentyna Tkachuk, Oleg Shehynskyi, Inna Parfentyeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.