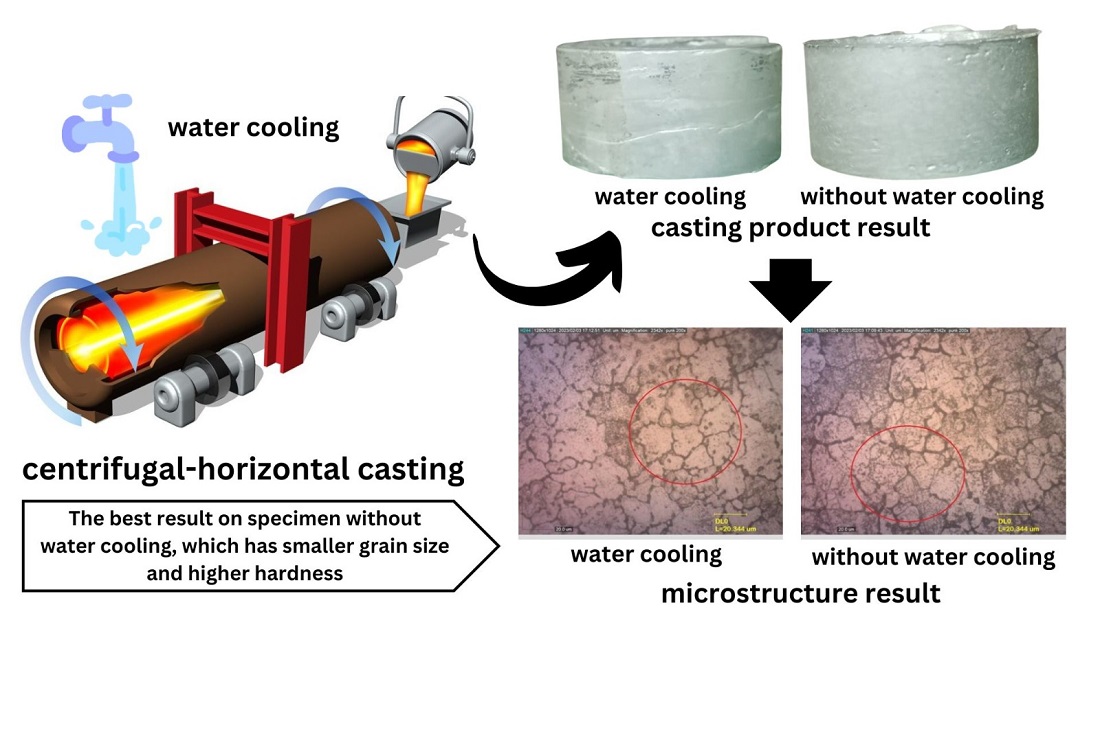

Comparison of the hardness value and microstructure of Al6061 in horizontal centrifugal casting with and without mold cooling

DOI:

https://doi.org/10.15587/1729-4061.2024.306262Keywords:

metal casting, horizontal centrifugal casting, mold cooling, hardness, microstructure, Al6061Abstract

The object of this research is the horizontal centrifugal casting process of the Al6061 alloy. Usually, cast products experience some casting defects, so the horizontal centrifugal casting process is applied to reduce the possibility of casting defects arising. In some casting processes, especially in the production of cylindrical specimens, casting defects such as porosity are encountered. Therefore, horizontal centrifugal casting was applied to overcome this problem. The test results show that the average hardness value for aluminum 6061 specimens resulting from centrifugal casting products with water cooling was 73.3 HRE, while the average hardness value for aluminum 6061 specimens resulting from centrifugal casting products without water cooling was 86.4 HRE. The microstructure results show that the grain size of centrifugal casting products with water cooling was 82.5 µm, whereas without water cooling it was 75 µm. Higher hardness values were obtained in specimens without mold cooling, this is because the conductivity in molds without cooling was higher compared to molds that experienced water cooling. The higher the heat conductivity of the mold, the faster the cooling process of the cast product. The casting process using the horizontal centrifugal method can be carried out to produce cylindrical spare parts

References

- Tsamroh, D. I. (2021). Comparison finite element analysis on duralium strength against multistage artificial aging process. Archives of Materials Science and Engineering, 1 (109), 29–34. https://doi.org/10.5604/01.3001.0015.0512

- Sun, Y. (2023). The use of aluminum alloys in structures: Review and outlook. Structures, 57, 105290. https://doi.org/10.1016/j.istruc.2023.105290

- Kumar, B., Joshi, A., Mer, K. K. S., Prasad, L., Pathak, M. K., Saxena, K. K. (2022). The impact of centrifugal casting processing parameters on the wear behaviour of Al alloy/Al2O3 functionally graded materials. Materials Today: Proceedings, 62, 2780–2786. https://doi.org/10.1016/j.matpr.2022.01.408

- Ogunsemi, B. T., Abioye, T. E., Ogedengbe, T. I., Zuhailawati, H. (2021). A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. Journal of Materials Research and Technology, 11, 1061–1089. https://doi.org/10.1016/j.jmrt.2021.01.070

- Fathi, R., Ma, A., Saleh, B., Xu, Q., Jiang, J. (2020). Investigation on mechanical properties and wear performance of functionally graded AZ91-SiCp composites via centrifugal casting. Materials Today Communications, 24, 101169. https://doi.org/10.1016/j.mtcomm.2020.101169

- Chandran, V., Kunjan, C., Veerapandian, V., Kannan, R. (2023). Mechanical, corrosion and biological behavior of centrifugal casting processed Mg–2Zn–1Mn alloy reinforced with β Tricalciumphosphate (βTCP) for orthopaedic applications. Journal of the Mechanical Behavior of Biomedical Materials, 144, 105983. https://doi.org/10.1016/j.jmbbm.2023.105983

- Li, B., Bai, W., Yang, K., Hu, C., Wei, G., Liu, J. et al. (2024). Revealing the microstructural evolution and strengthening mechanism of Mg-5.5Gd-3Y-1Zn-0.5Mn alloy in centrifugal casting and subsequent hot rolling. Journal of Alloys and Compounds, 984, 173950. https://doi.org/10.1016/j.jallcom.2024.173950

- Ma, Z., Li, G., Peng, Q., Peng, X., Chen, D., Zhang, H. et al. (2022). Microstructural evolution and enhanced mechanical properties of Mg–Gd–Y–Zn–Zr alloy via centrifugal casting, ring-rolling and aging. Journal of Magnesium and Alloys, 10 (1), 119–128. https://doi.org/10.1016/j.jma.2020.11.009

- Li, Y., Shen, B., Yang, H., Hu, G., Yang, D., Wang, J. et al. (2023). Alumina nanocrystalline ceramic by centrifugal casting. Journal of the European Ceramic Society, 43 (4), 1590–1596. https://doi.org/10.1016/j.jeurceramsoc.2022.12.004

- Ali, S. M. (2019). The effect of reinforced SiC on the mechanical properties of the fabricated hypoeutectic Al-Si alloy by centrifugal casting. Engineering Science and Technology, an International Journal, 22 (4), 1125–1135. https://doi.org/10.1016/j.jestch.2019.02.009

- Oktikawati, A., Riastuti, R., Damisih, D., Nyoman Jujur, I., Paul Setiawan Kaban, A. (2024). Electrochemical characteristic and microstructure of Ti-6Al-7Nb alloy by centrifugal casting for orthopedic implant based on ageing time variations. Materials Science, 2 (12 (128)), 6–15. https://doi.org/10.15587/1729-4061.2024.302614

- Nafiuddin, I., Samsudi, S. (2020). Pengaruh Variasi Putaran Cetakan Pengecoran Sentrifugal Tegak pada Pengecoran Paduan Aluminium terhadap Ketangguhan Impak dan Struktur Mikro Pembuatan Velg Gokart. JMEL: Journal of Mechanical Engineering Learning, 9 (1). Available at: https://journal.unnes.ac.id/sju/jmel/article/view/39624

- Manurung, F. F., Mahadi, M. (2022). Studi Eksperimental Pengaruh Variasi Temperatur Pemanasan Awal Cetakan Horizontal Centrifugal Casting Pada Pengecoran Al-Si Terhadap Sifat Mekanik Dan Cacat Coran. Dinamis, 10 (2), 46–52. https://doi.org/10.32734/dinamis.v10i2.10270

- Xin, M., Wang, Z., Lu, B., Li, Y. (2022). Effects of different process parameters on microstructure evolution and mechanical properties of 2060 Al–Li alloy during vacuum centrifugal casting. Journal of Materials Research and Technology, 21, 54–68. https://doi.org/10.1016/j.jmrt.2022.08.147

- Mubarok, A. K. (2017). Pengaruh Variasi Temperatur Awal Cetakan Centrifugal Casting Terhadap Nilai Kekerasan dan Struktur Mikro pada Pengecoran Aluminium Berbahan Piston Bekas. Universitas Negeri Semarang. Available at: https://lib.unnes.ac.id/30811/1/5201413010.pdf

- Bintoro, W. M., Undiana, B., Duddy, Y. P. (2014). Penerapan Metode Sentrifugal pada Proses Pengecoran Produk Komponen Otomotif Velg Sepeda Motor. Jurnal Energi Dan Manufaktur, 6 (2), 135–142.

- Florenciano, J. T. O., Ambrosi, A., Hotza, D., González, S. Y. G. (2022). Understanding centrifugal casting in the manufacture of functionally graded materials. Journal of the European Ceramic Society, 42 (15), 7089–7101. https://doi.org/10.1016/j.jeurceramsoc.2022.08.042

- Zygmuntowicz, J., Tomaszewska, J., Jeleń, J., Piotrkiewicz, P., Wachowski, M., Torzewski, J., Żurowski, R. (2022). Comprehensive analysis of the microstructure, properties and environmental performance of Al2O3-ZrO2 composites obtained via centrifugal slip casting. Chemical Engineering Science, 263, 118086. https://doi.org/10.1016/j.ces.2022.118086

- Darmadi, D. B., Talice, M. (2021). Improving the strength of friction stir welded joint by double side friction welding and varying pin geometry. Engineering Science and Technology, an International Journal, 24 (3), 637–647. https://doi.org/10.1016/j.jestch.2020.11.001

- Tsamroh, D. I., Riza Fauzy, M. (2022). Peningkatan Sifat Mekanik Al6061 Melalui Heat Treatment Natural-Artificial Aging. G-Tech: Jurnal Teknologi Terapan, 6 (1), 8–13. https://doi.org/10.33379/gtech.v6i1.1217

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Agus Suprapto, Dewi Izzatus Tsamroh, Djoko Andrijono, Septian Dwi Irianto Maswain

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.